Thank you for choosing Tamerica’s TCC-1655HC Laminating Machine, designed to

provide years of usefu service for your amination needs. Upon receipt, p ease in-

spect the box/crate, the machine, and a other contents for any signs of shipping

damage which shou d immediate y be brought to the attention of the de ivery carrier.

For comp ete operating and maintenance information, p ease read this manua thor-

ough y.

Fai ure to comp y with any of the fo owing safety procedures cou d

resu t in serious injury. P ease read the instructions carefu y and

keep this manua for future reference.

1. A icensed e ectrician shou d insta the proper out et for the wiring of the

machine.

2. Ensure machine is p ugged into a proper y grounded out et with correct vo t-

age.

3. Do not a ow artic es of c othing (ex. ties, scarves, etc.) near the machine

openings as they cou d get caught by the ro ers and pu ed inside causing

serious persona injury.

4. Keep machine away from anything f ammab e and insta in a dry ocation.

5. To prevent the possibi ity of e ectric shock, do not immerse machine in wa-

ter or a ow iquid to spi inside.

6. Avoid excessive sun ight, humidity and extreme temperatures.

7. Ensure that the machine is turned off, has coo ed down, and is unp ugged

from the out et prior to moving or performing repairs.

8. Keep chi dren away.

9. Do not open the case without being authorized by a technician.

10. Do not attempt to aminate items that exceed tota recommended materia

thickness for the unit.

WARNING: The laminator should be installed by a trained service

technician

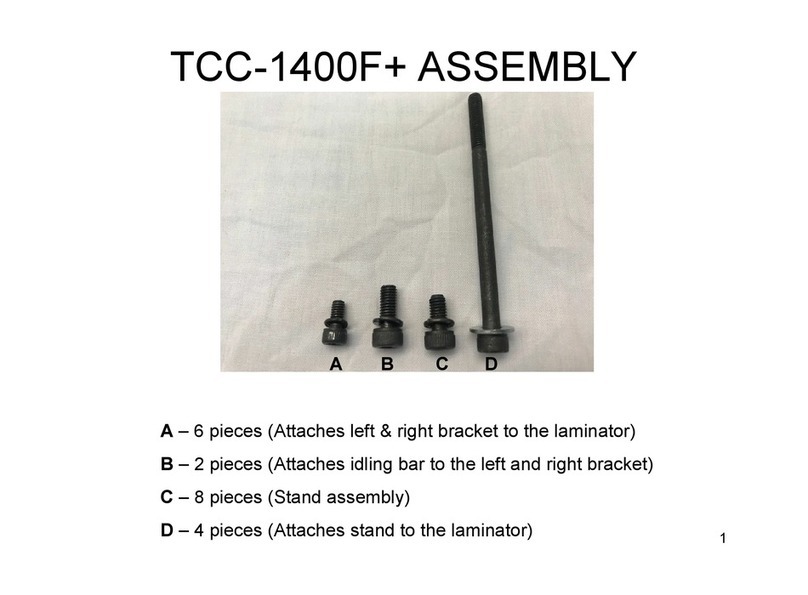

The aminator is shipped with the stand disassemb ed and the feed tab e unat-

tached to avoid any damage whi e in transit. Upon arriva , thorough y inspect the

machine for any signs of damage or ma function which shou d immediate y be re-

ported to the carrier and dea er and/or manufacturer for proper fi ing of any c aim

or warranty rep acement/repair.

The aminator shou d be ocated in an area with adequate work space for feeding

graphics and aminating materia s. Avoid p acing in dusty areas or near sources of

extreme heat or co d. Once the aminator is proper y situated, ock the casters into

position and on y un ock when moving to a different ocation.

INTRODUCTION

SAFETY PRECAUTIONS

INSTALLATION

4