Page 4

iQSeries,Auto-Plus User’s Manual

Dukane Manual Part No. 403-591-01

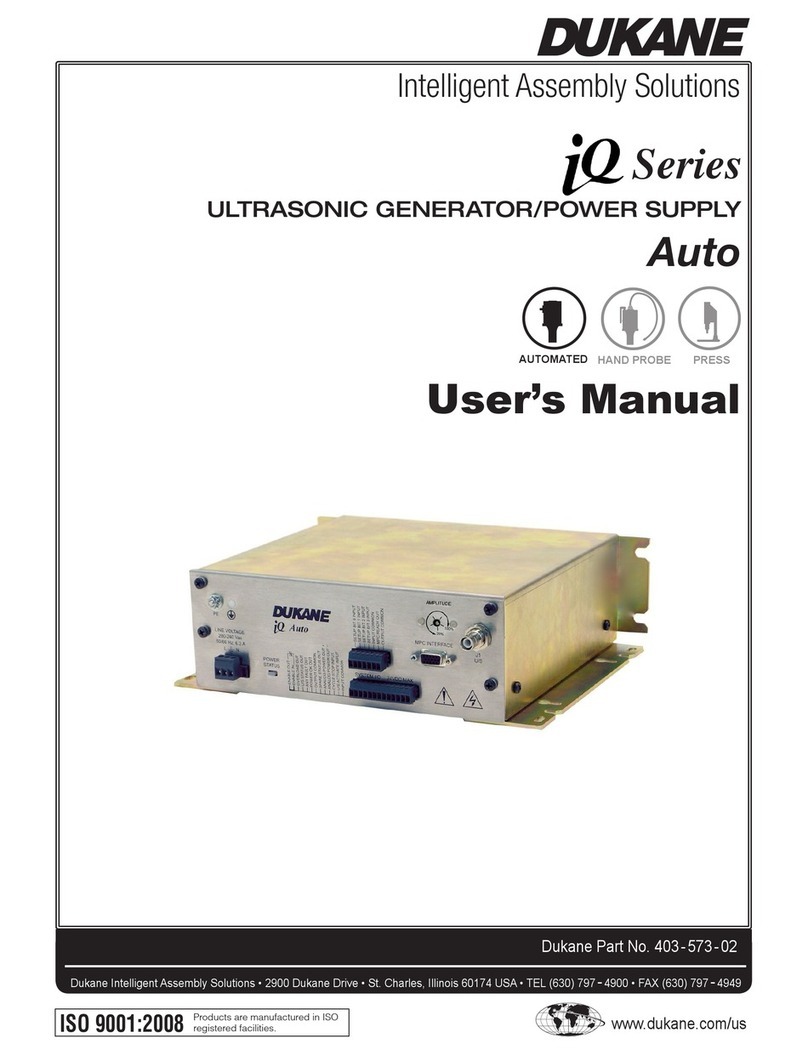

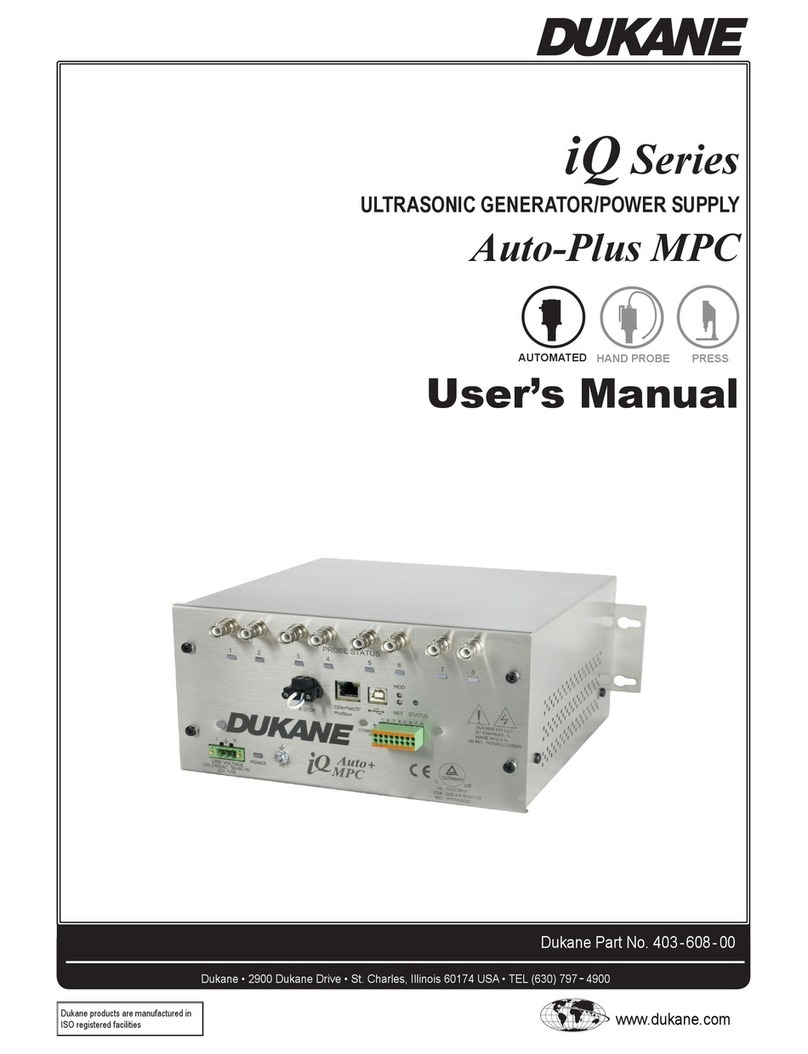

Generator Overview

This generator is designed for ultrasonic applications con-

trolled by a Programmable Logic Controller (PLC). Us-

ing the available system control inputs and outputs, the

generator can easily be integrated into a wide variety of

automated systems.

The generator design accepts several control input signals,

provides system output signals, has a variety of status LED

indicators, and built-in USB and EtherNet connectors.

The Multi-Probe Control (MPC) interface allows the gen-

erator to power multiple probes selected by an automated

control system.

This product’s rugged internal ultrasonic generator cir-

cuitry ensures a continuous resonant frequency lock at

the start of each weld. Users can modify generator per-

formance to meet a wide variety of ultrasonic processing

requirements if needed.

The generator’s compact size allows multiple units to be

placed into an industrial equipment cabinet, and the gen-

erator will operate at the same international line voltage

input specications as the other generators of this product

family. It also includes an RFI line lter that passes strict

CE test specications for global applications.

Key Generator Features

• Compact Enclosure Size requires a small footprint for

either vertical or horizontal mounting into your equip-

ment cabinet.

• Pulse Width Modulation incorporates patented

circuitry giving the power supply the ability to

efciently change the output amplitude. This makes

it possible to start large horns with reduced power. It

also provides more power efcient switch-mode gen-

erator operation and increased reliability.

• Linear Ramp Soft Start circuitry allows the acous-

tic stack to ramp up to operating amplitude smoothly,

minimizing the startup surges and abnormal stress to

the stack and generator.

• Automatic Tuning tracks the resonant frequency of

the acoustic stack (horn, booster, transducer) and ad-

justs the generator output frequency to match it. This

is done for every weld cycle and eliminates the need

to manually tune the generator.

• Line Voltage Regulation automatically maintains

constant amplitude regardless of line voltage devia-

tion. The available output power is maintained with

any voltage input within the specied range. This

provides consistent system performance regardless of

line voltage uctuations. It also eliminates the need

for bulky, external constant–voltage transformers.

• Load Regulation provides constant amplitude auto-

matically regardless of power draw. The ultrasonic

output amplitude level is held to within ±1% to pro-

vide weld process consistency and reduced weld cycle

times.

• Power Factor Corrected Universal AC Power

Source means that standard 600 watt systems will

operate worldwide at all industrial high line voltage

levels, whether it is 100-200VAC @60Hz in Japan,

240VAC @50Hz in Europe or 100-240VAC @60Hz

in the United States. There are no internal transformer

taps to change for worldwide operation.

• Amplitude Adjustment Control allows the peak -to-

peak excursion of the horn at its workface to be ad-

justed between 20% and 100% of the horn’s nominal

amplitude.

• Multiple Electronic Overload protection circuits

prevent instantaneous component failure in the event

of extreme output overload conditions and rated over-

load power limit is based on the actual true RMS

power output level.

• Optional Weld by Distance Feature to monitor up

to four analog 0-10 VDC encoders (requires customer

supplied encoders).

• CE Certication means that the system meets the

required European standards to be sold and used in

Europe.

• ISO Certied means that this system has been manu-

factured to high quality standards and assures you of

manufacturing excellence.

• TUV Certication - TÜV Rheinland certies Dukane

products comply with applicable UL (Underwriters

Laboratories) and CSA (Canadian Standards Associa-

tion) requirements.