5 of 24

IN TALLATION IN TRUCTION

A. Qualified Personnel

These inst ll tion instructions re for the use of

qu lified inst ll tion nd service personnel only.

Inst ll tion or service by other th n qu lified

personnel m y result in d m ge to the oven

nd/or injury to the oper tor.

Qu lified inst ll tion personnel re those individu ls, firms,

comp nies or corpor tions which either in person or

through n gent re eng ged in nd responsible for:

•The inst ll tion of electric l wiring from the

electric meter, m in control box or service

outlet to the electric l ppli nce. Qu lified

inst ll tion personnel must be f mili r with ll

prec utions required nd h ve complied with ll

requirements of st te nd loc l uthorities

h ving jurisdiction. See: N tion l Electric l

code, ANSI/NFPA 70-1990.

B. Delivery and Inspection

Duke M nuf cturing Co., does everything within its power

to insure you receive your oven in good condition. They

re str pped down on he vy wooden skids nd surrounded

by he vy "tri-w ll" c rtons to prevent shipping d m ge.

They h ve ll been c refully inspected before they were

p ck ged nd consigned to the c rrier.

Upon Delivery of your Duke oven:

•Look over the shipping cont iner c refully

noting ny exterior d m ge on the delivery

receipt which must lso be signed by the

driver/delivery person.

•Uncr te nd check for ny d m ge which w s

not evident on the outside of the shipping

cont iner. This is c lled conce led d m ge.

The c rrier must be notified within fifteen (15)

d ys of the delivery of the oven nd the c rton,

skid nd ll p ck ging m teri ls must be

ret ined for inspection.

Duke M nuf cturing Co. c nnot ssume li bility for loss or

d m ge suffered in tr nsit. The c rrier ssumes full

responsibility for delivery in good order

when the shipment w s ccepted. However, we re

prep red to ssist you in filing ny freight cl im.

C. Location of the Oven

Proper pl nning nd pl cement of the oven will give you

the best results in terms of long term user convenience nd

s tisf ctory perform nce. We urge you to give dequ te

thought in the pl cement of your oven prior to its rriv l.

•The oven should be pl ced in n re which is

free from dr fts nd ccessible for proper

oper tion nd servicing.

•The re round the oven must be kept cle r of

combustible m teri ls. A minimum of one (1)

inch from the left or right side, three (3) inches

from the re r nd eight (8) inches from the floor

must be m int ined between the oven nd ny

combustible or non-combustible surf ce.

It is lso import nt not to obstruct the n tur l flow of

ventil tion ir if the oven is to oper te properly. Do

not pl ce ny objects on top of the oven. This oven

should not be inst lled on curb b se or se led to the

w ll. Either condition c n prevent proper ventil tion

of the blower motor. The blower motor h s therm l

protection device which will trip bec use of excessive

mbient temper tures t the side of the oven. If the

device trips continu lly, this condition should be

corrected immedi tely to void d m ging the oven

perm nently.

Before m king ny connections to the over, check the r ting

pl te to be sure the oven specific tions concur with the

volt ge nd ph se to be supplied to the oven.

The r ting pl te nd seri l number d t re loc ted behind

the motor ccess cover on the right side p nel.

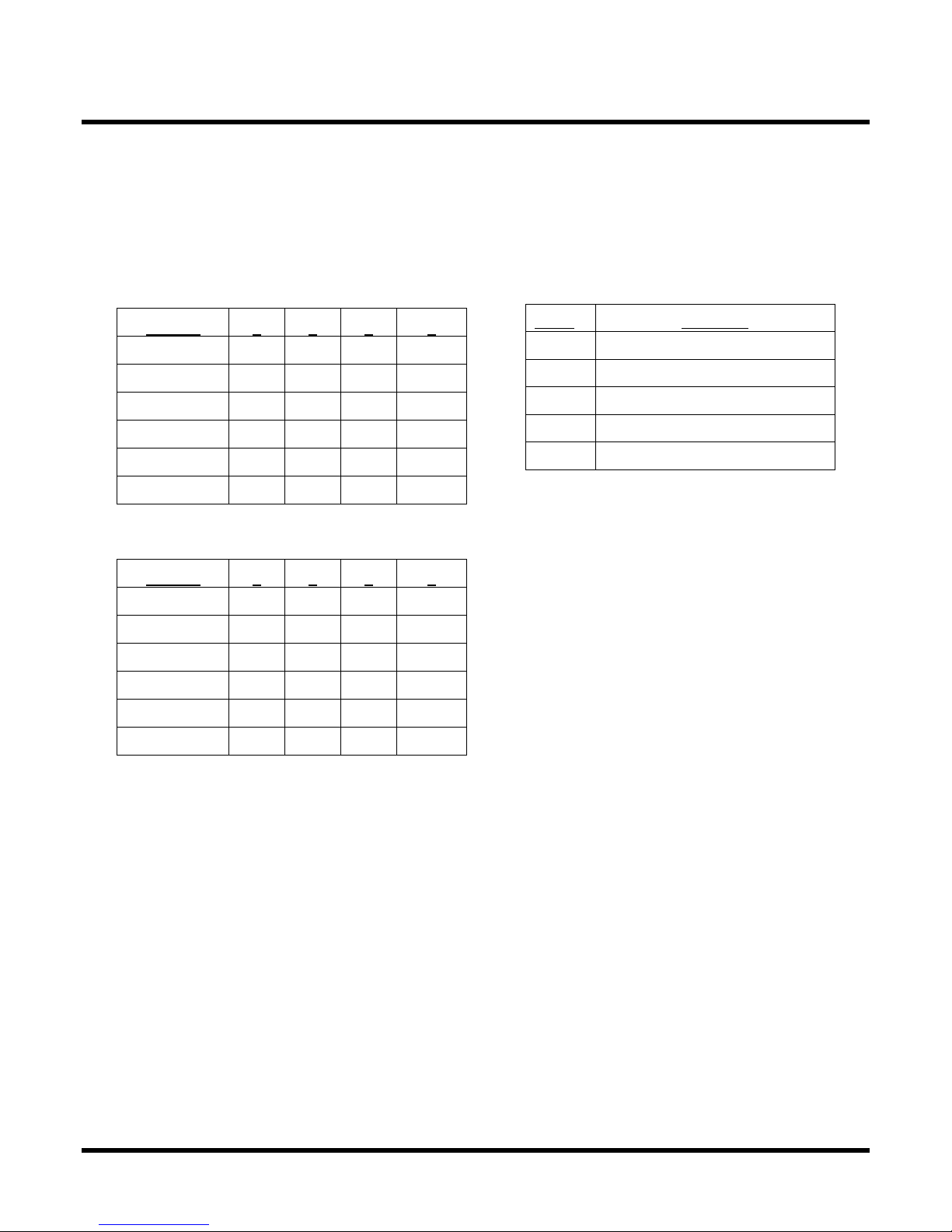

D. Electrical Connections

E ch section of the Duke 5/9 H lf-Size Convection Ovens

is r ted t 8.0 KW.

Your oven is supplied for connection to 208 or 240 volt,

1-ph se or 3-ph se grounded circuit. The

electric motor, indic tor lights nd control circuits re

powered intern lly nd do not h ve sep r te power

supply.

Before m king ny connections to these units, check the

r ting pl te to ssure th t the volt ge nd ph se r ting of the

oven is comp tible with the electric l supply. When

inst lling, ll ovens must be electric lly grounded in

ccord nce with loc l codes or in the bsence of loc l

codes, with the N tion l Electric l Code, ANSI/NFPA 70-

1990 (in C n d - CSA Std. C22.1).