10

Installation and Operation of: DUKE TSC3 Proofer Oven with Touch Screen Controls

INSTALLATION

UNPACKING UNIT

Inspect the shipping carton and/or container,

carefully noting any exterior damage on the

delivery receipt; also note any damage not evident

on the outside of the shipping container (concealed

damage). Contact the carrier immediately and le a

damage claim with them. Save all packing materials

when ling a claim. Freight damage claims are the

responsibility of the purchaser and are not covered

by the warranty.

• Follow the instructions on the Carton Box for

unpacking the unit.

• Inspect unit for damage such as, broken glass,

etc.

• Report any dents or breakage to source of

purchase immediately.

• Do not attempt to use unit if damaged.

• Remove all materials from unit interior.

• If unit has been stored in extremely cold area,

wait a few hours before connecting power.

UNIT PLACEMENT

• Do not install unit next to source of heat, such

as deep fryer, etc.

• Install unit on level surface oor.

• Minimum Clearance of 6" (152mm) must

be maintained between the unit and any

combustible substance.

• Either side of the unit must remain open for

proper airow for electrical component cooling.

The rear of the unit and one side may be

installed without clearance.

ELECTRICAL AND SUPPLY CONNECTIONS

Connection of the unit to the mains supply

MUST be performed by an authorized person

in accordance with codes, standards, and laws

governing the installation site using properly rated

all poles mains protection, full disconnection under

over voltage category III, safety ground earthing,

and shall be a minimum of 48" (1.2 meter) long to

allow the equipment to be moved for cleaning.

USA and non-EU Countries must use exible

conduit within variances that may be required by

local electric codes or regulations.

All International installations must use IEC 60245

IEC 66, HO7RN-F, minimum 5G 2,5mm, 5G4.0mm

maximum exible cordage.

For 1~ appliances use minimum 3G 4.0mm, 3G

6.0mm maximum exible cordage.

The Mains Supply safety / earth ground wire must

be longer than mains conductors at the unit's

interconnections to prevent stress under pull.

Contact Duke for service of IVS (Integrated

Ventilation System) HO5RN supply interconnection.

EXTERNAL EQUIPOTENTIAL

Terminal provides a connection for bonding to

equipment enclosure.

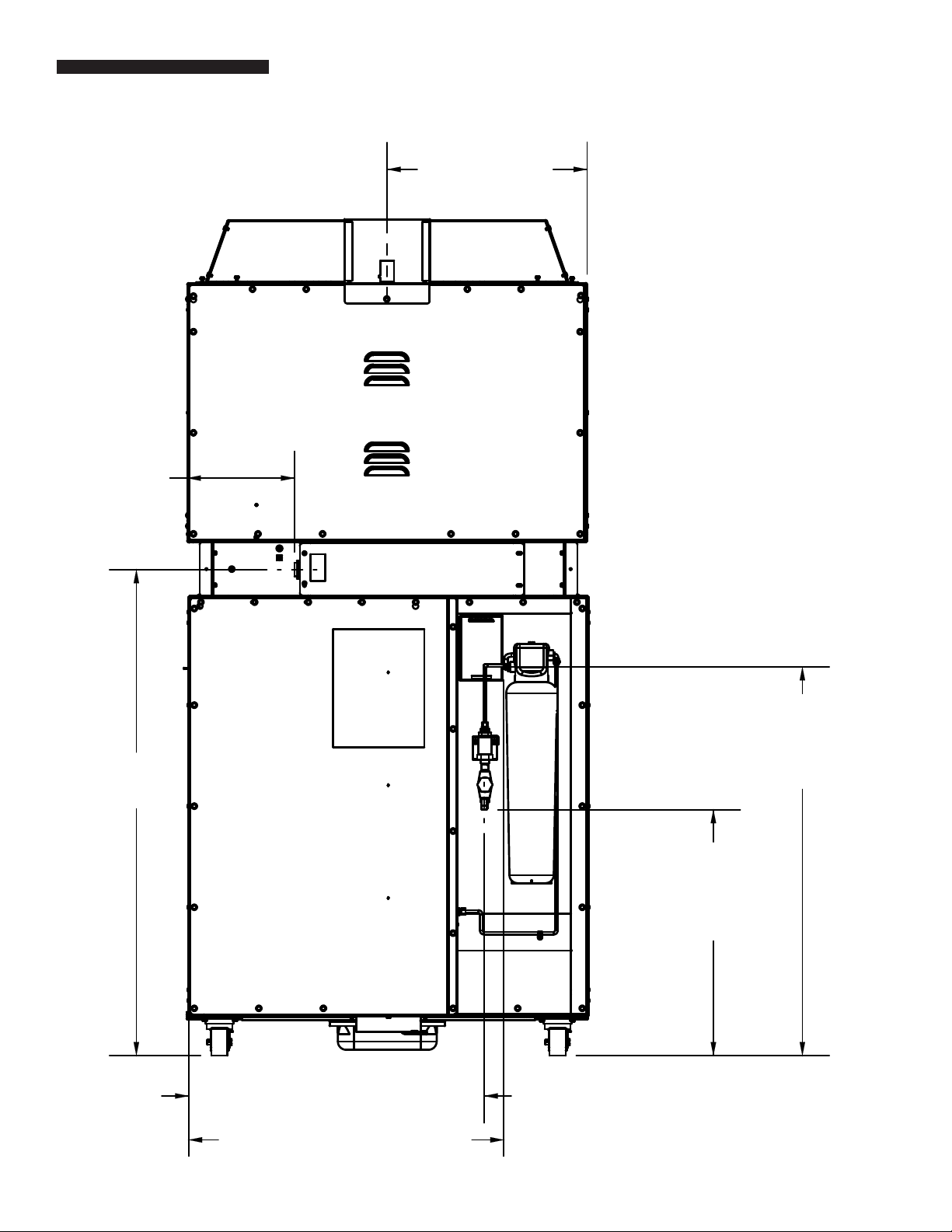

WATER SUPPLY CONNECTION

This equipment must be installed in accordance

with all applicable federal, state, and/or local

plumbing codes having jurisdiction.

The water inlet utilizes ¼” (6.35mm), OD plastic

tubing. Install the tubing in a manner to ensure

there are no kinks, strains, or tight bends. Leave

sucient length to allow unit movement for service

and cleaning.

The tubing should be cut square and be free of any

deformations at the connection points. All burrs

and sharp edges should be removed for proper

connection.

Insert the tubing through the compression tting

with the threads pointing towards the end of the

tubing.

Push the tubing into the tting as far as it will go

and tighten the nut with a ½” (12.7mm), wrench.

Do not over-tighten the nut. If leaks occur, further

tighten the tting until the leakage stops.

ELECTRICAL SHOCK HAZARD UNIT MUST BE

SAFETY GROUNDED, EARTHED.

DO NOT MODIFY OR DEFEAT ELECTRICAL

CONNECTIONS