5 of 28

INSTALLATION INSTRUCTIONS

A. Qualified Personnel

These installation instructions are for the use of

qualified installation and service personnel only.

Installation or service by other than qualified service

personnel may result in damage to the oven and/or

injury to the operator.

Qualified installation personnel are those individuals,

firms, companies or corporations which either in

person or through an agent are engaged in and

responsible for:

The installation of electrical wiring from the

electric meter, main control box or service

outlet to the electrical appliance. Qualified

installation personnel must be familiar with

all precautions required and have complied

with all requirements of state and local

authorities having jurisdiction.

B. Delivery and Inspection

For transport, ovens are strapped down on wooden

skids and surrounded by "tri-wall" cartons to prevent

shipping damage. They have been carefully

inspected before they were packaged and

consigned to the carrier.

Upon Delivery of your Duke oven:

Look over the shipping container carefully

noting any exterior damage on the

delivery receipt.

Uncrate and check for any damage which

was not evident on the outside of the

shipping container. The carrier must be

notified within fifteen (15) days of the

delivery of the oven and the carton, skid

and all packaging materials must be

retained for inspection.

Duke Manufacturing Co. cannot assume liability for

loss or damage suffered in transit. The carrier

assumes full responsibility for the delivery in good

order when the shipment was accepted. If you need

assistance in preparing a freight claim call Duke

Manufacturing Co.

C. Location of the Oven

Proper planning and placement of the oven is

required for the proper function of the oven. Please

do consider the following requirements:

The oven should be placed in an area

which is free from drafts and accessible

for proper operation and servicing.

The area around the oven must be kept

clear of combustible materials. A minimum

of one (1) inch from the left or right side,

three (3) inches from the rear and eight (8)

inches from the floor must be maintained

between the oven and any combustible or

non-combustible surface.

D. Ventilation

It is important not to obstruct the cooling system flow

of the oven. Do not place any objects on top of the

oven. This oven should not be installed on a curb

base or sealed to the wall. Either condition can

prevent proper ventilation of the oven components.

The blower motor has a thermal protection device,

which will trip because of excessive ambient

temperatures at the side of the oven. If the device

trips continually, this condition should be corrected

immediately to avoid damaging the oven

permanently.

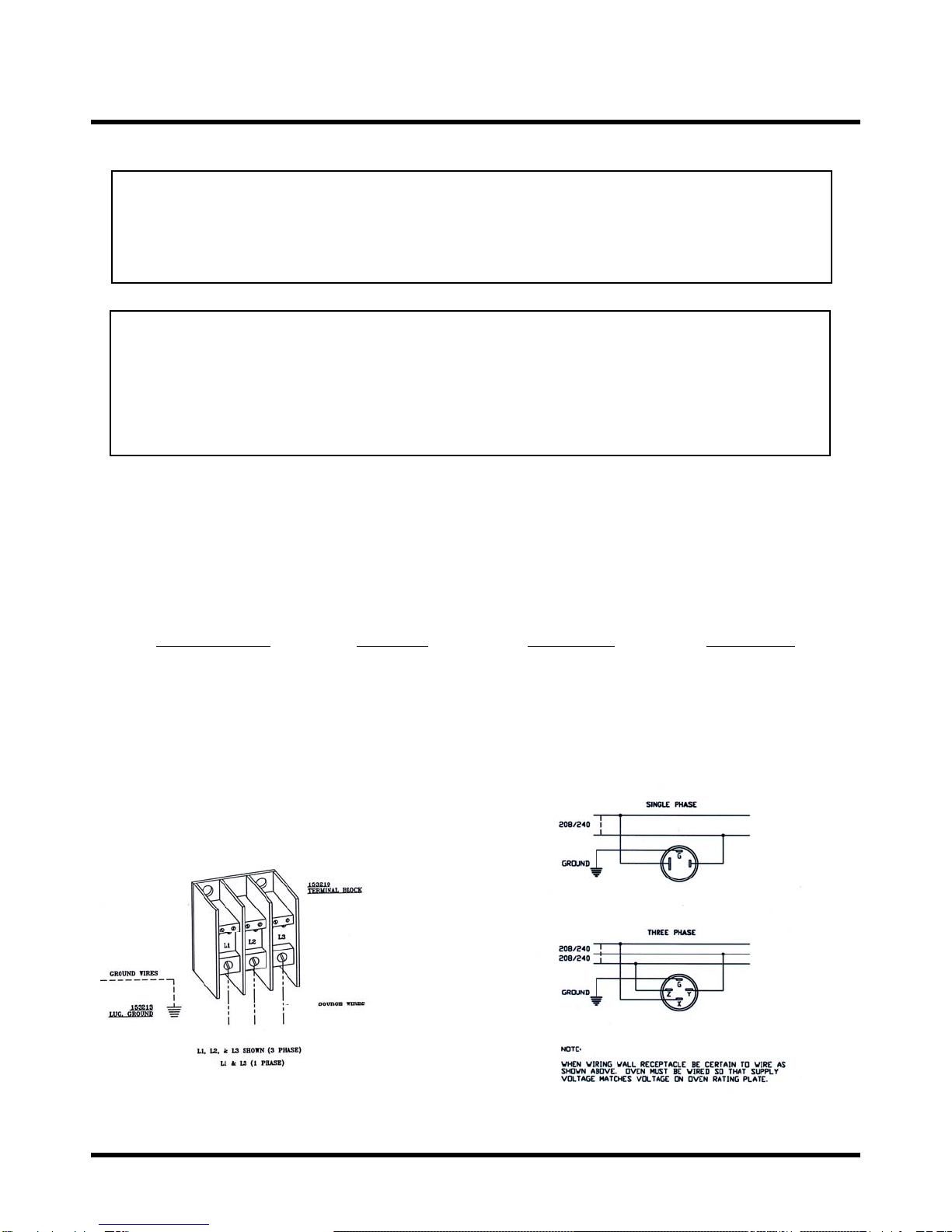

E. Electrical Connections

Verify the rating plate to be sure the oven

specifications concur with the voltage and phase to

be supplied to the oven. The rating plate and serial

number data are located behind the motor access

cover on the right side panel.

The following installation steps should only be

conducted by authorized service personnel or a

qualified electrician.

Your oven is supplied for connection to a 208 or 240

volt, 1-phase or 3-phase grounded circuit.

Before making any connections to these units, check

the rating plate to assure that the voltage and phase

rating of the oven is compatible with the electrical

supply. All ovens must be electrically grounded in

accordance with local codes. In the absence of local

codes, the National Electrical Code, ANSI/NFPA 70-

1990 (in Canada - CSA Std. C22.1) applies.