DukeManufacturingCo.

2305 N. Broadway • St. Louis, MO 63102

800.735.3853 • 3.231.1130 • 314.231.5074 Fax

www.dukemfg.com

3 of 29

IMPORTANT SAFETY INSTRUCTIONS

Throughoutthismanual,youwill find the following safetywordsandsymbolsthat signify important safety issues

withregardsto operating ormaintaining the equipment.

GENERAL WARNING. Indicates informa-

tion important to the proper operation of

the equipment. Failure to observe may

result in damage to the equipment and/

or severe bodily injury or death.

WARNING

ELECTRICAL WARNING. Indicates infor-

mation relating to possible shock hazard.

Failure to observe may result in damage

to the equipment and/or severe bodily

injury or death.

WARNING

GENERAL CAUTION. Indicates informa-

tion important to the proper operation of

the equipment. Failure to observe may

result in damage to the equipment.

CAUTION

HOT SURFACE WARNING. Indicates in-

formation important to the handling of

equipment and parts. Failure to observe

caution could result in personal injury.

WARNING

In addition to the warnings and cautions in this manual,

usethefollowingguidelines forsafeoperationoftheunit.

• Readallinstructions before usingequipment.

• For your safety, the equipment must be furnished

with a properly grounded cord connector. Do not

attempttodefeat the groundedconnector.

• Install or locate the equipment only for its intended

use as described in this manual.

• Do not use corrosive chemicals in this equipment.

• Do not operate this equipment if it has a damaged

cord or plug, if it is not working properly, or if it has

beendamagedordropped.

• Thisequipmentshould be servicedby qualified per-

sonnel only. Contact the nearest Duke authorized

servicefacility for adjustment orrepair.

• Do not block any openings on the unit.

• Aminimum clearance of6” (152,4 mm)from the top

of the unit to the ceiling must be provided.

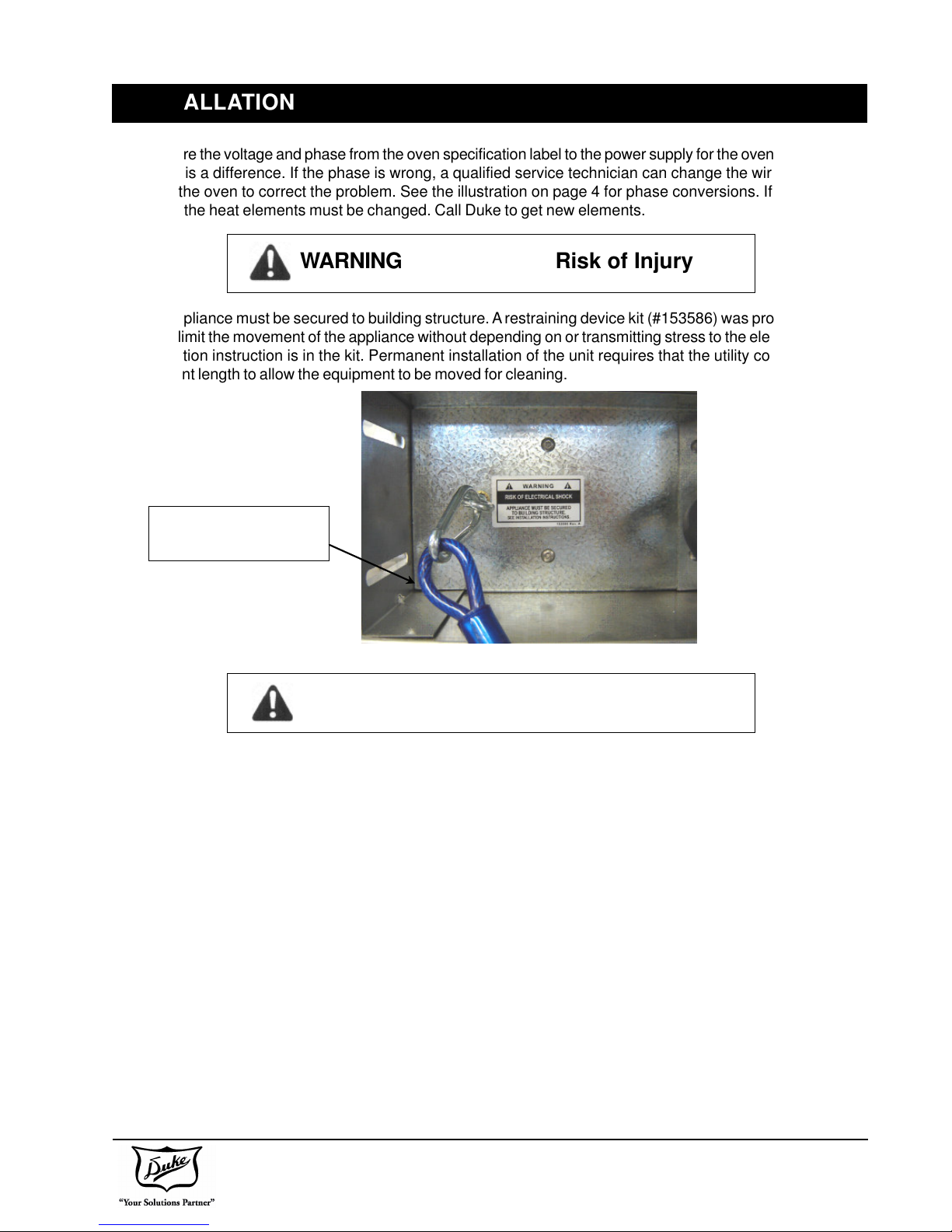

• Thisappliancemustbesecuredtobuildingstructure

(RestrainingDeviceKit).

• Keepcordaway from heatedsurfaces.

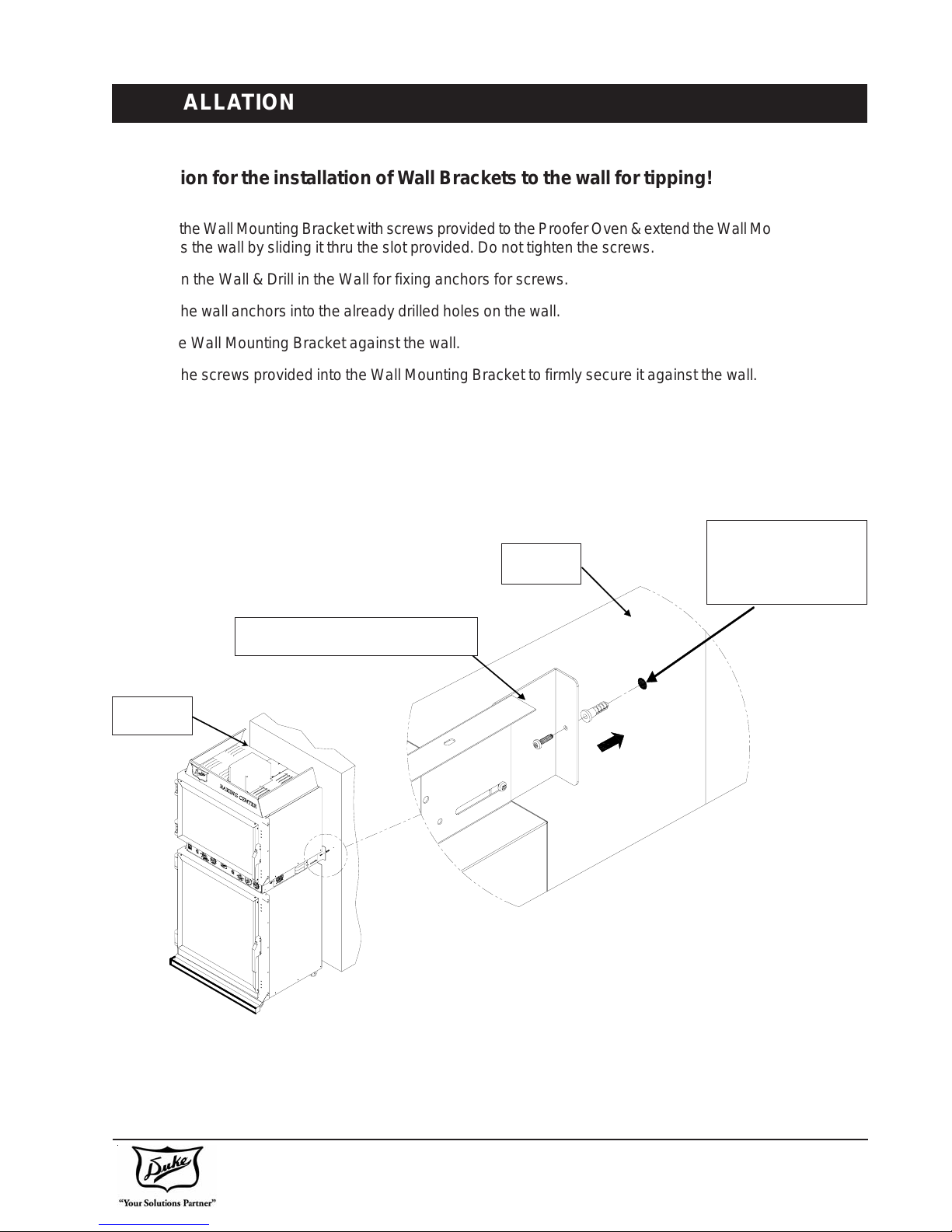

• To prevent tipping, securely attach unit to the wall

usingbracketsprovided.

Thefollowingwarningsandcautionsappearthroughout

thismanualand should be carefullyobserved.

• Turn the unit off, disconnect the power source and

allowunittocooldownbeforeperforminganyservice

ormaintenance onthe unit.

• The procedures in this manual may include the use

of chemical products. You must read the Material

SafetyData Sheets before using anyof these prod-

ucts.

• Theunitshouldbegroundedaccordingtolocalelec-

trical codes to prevent the possibility of electrical

shock. Itrequiresa grounded receptacle withsepa-

rate electrical lines, protected by fuses or circuit

breakeroftheproperrating.

• Allelectricalconnectionsmustbeinaccordancewith

local electrical codes and / or any other applicable

codes.

• Disposal of the unit must be in accordance with lo-

calenvironmentalcodesand/oranyotherapplicable

codes.

SAVE THESE INSTRUCTIONS