www.factorybuysdirect.com 200366-01B4

WARNING: Do not use a

blower insert, heat exchanger

insert or any accessory not ap-

proved for use with this log set.

WARNING: Do not allow fans

to blow directly into the heater.

Avoid any drafts that alter burner

ame pattern including ceiling

fans. Altered burner patterns

can cause sooting.

WARNING: FIRE,EXPLOSION

AND ASPHYXIATION HAZARD

Improper adjustment, alteration,

service, maintenance, or installa-

tion of this heater or its controls

can cause death or serious injury.

Read and follow instructions and

precautionsinUser's Information

Manual provided with this heater.

WARNING: Do not place cloth-

ing or other ammable material

on or near the appliance. Never

place any objects in the heater.

WARNING: Due to high tem-

peratures, the appliance should

be located out of trac and away

from furniture and draperies.

WARNING: Heater becomes

very hot when running. Keep

children andadults awayfrom hot

surfaces to avoid burns or cloth-

ing ignition. Heater will remain

hot for a time after shuto. Allow

surfaces to cool before touching.

WARNING: Carefully super-

vise young children when they

are in the room with the heater.

WARNING: Make sure a re-

place screen is in place before

running heater.

SAFETY

1. Do not place propane supply tank(s) in-

side any structure. Propane supply tank(s)

must be placed outdoors.

2. This heater should not be installed in a

bedroom or bathroom unless installed as

a vented appliance.

3. This heater needs fresh air ventilation to

run properly. This heater has an Oxygen

Depletion Sensing (ODS) safety shuto

system. The ODS shuts down the heater

if not enough fresh air is available. See

Air for Combustion and Ventilation, pages

6 and 7. If heater keeps shutting o, see

Troubleshooting, page 21.

4. Do not add extra logs or ornaments such

as pine cones, vermiculite, or rock wool.

Using these added items can cause soot-

ing. Do not add lava rock around base.

Rock and debris could fall into the control

area of heater. After servicing, always

replace screen before operating heater.

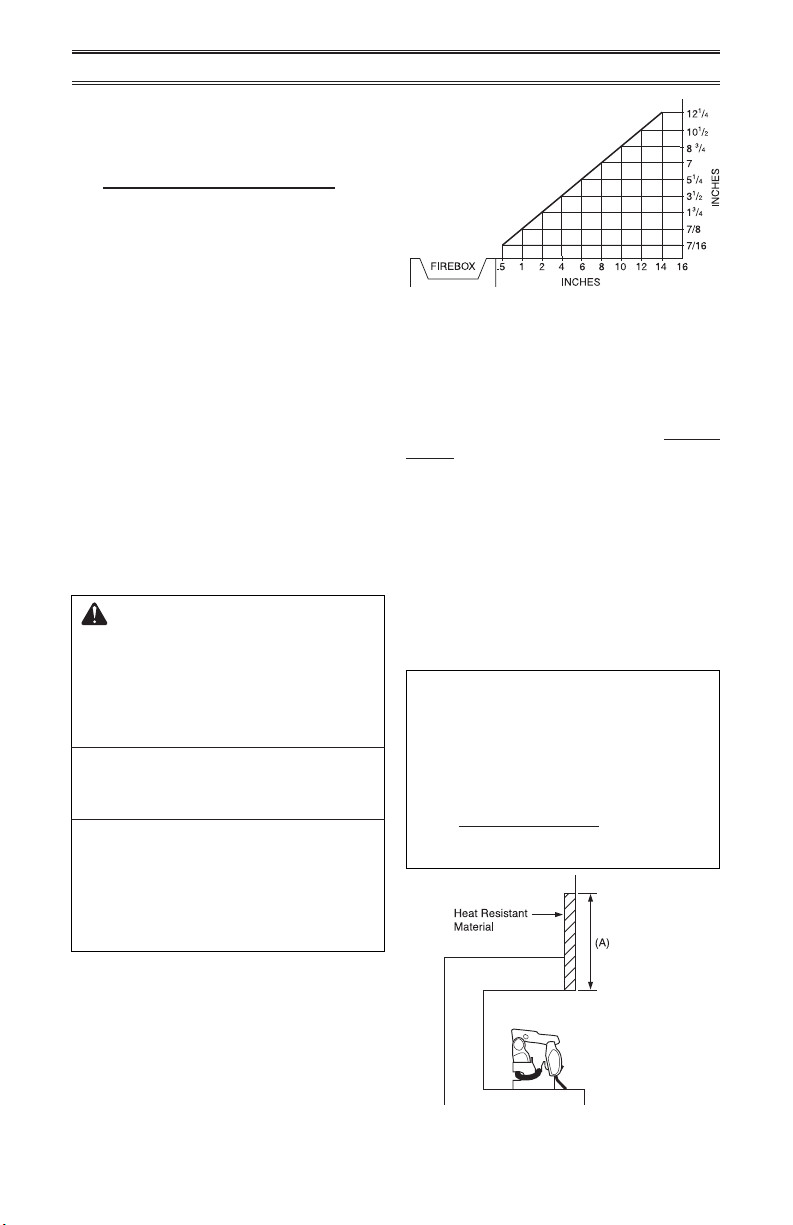

5. If replace has glass doors, never operate

this heater with glass doors closed. If you

operate heater with doors closed, heat will

build-up inside replace and cause glass

to burst. If replace opening has vents

at the bottom, you must open the vents

before operating log set. Always operate

heater with glass doors fully open.

6. This log heater is designed to be smokeless.

If logs ever appear to be smoking, turn o

heater and call a qualied service techni-

cian. NOTE: During initial operating, slight

smoking could occur due to log curing and

heater burning o manufacturing residues.

7. To prevent the creation of soot, follow the

instructions under Care and Maintenance

page 20.

8. Do not run heater:

• Where ammable liquids or vapors are

used or stored.

• Under dusty conditions.

9. Before using furniture polish, wax, carpet

cleaner, or similar products, turn heater o.

If heated, the vapors from these products

may create a white powder residue within

burner box or on adjacent walls or furniture.

10. Do not use heater if any part has been

under water. Immediately call a qualied

service technician to inspect the room

heater and to replace any part of the

control system and any gas control which

has been under water.