BX308XPGasDetectionController

t: 01905 797989

BX308 XP 8 Sensor Gas Detection Controller

FEATURES

■Eight sensors

■Datalogging Facility

■Wall mounted

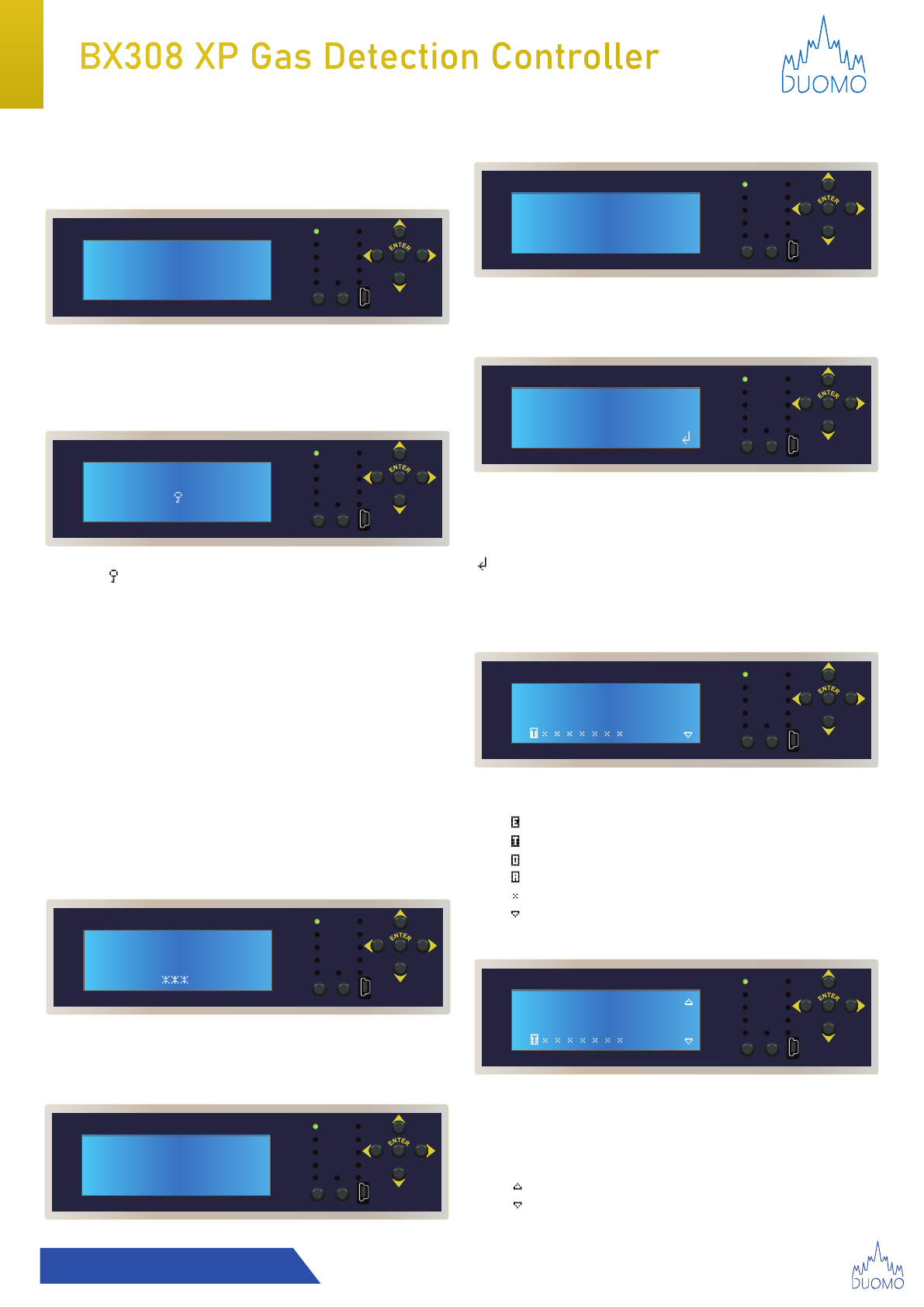

■Illuminated digital display

■Detection of Toxic 0-300ppm / Explosive Gas(es)

0-20%LEL

■4-20mA signal sensor input

■2 alarm stages - Pre-alarm and main alarm

■IP65 protective rating

■CE certied and approved to EN 50194 EN 50291 EMC

EN50270

■3 years guarantee

OVERVIEW

The control unit BX308 XP has been designed and built to meet

the current requirements of the Market and in compliance with

European Standard for checking gas presence in a versatile and

innovative using conventional sensors.

Up to 8 remote sensors from 4-20mA can be connected in

conventional mode for a single area. Gas concentration measured

by each sensor is sequentially shown on display, with a location

description.

When one of the connected sensors exceeds pre-alarm or main

alarm setpoints, the control unit activates the internal audible alarm,

depending on the concentration of gas measured, and shows on the

display the number of the sensor the amount of gas measured and

its origin; the alarm triggered is saved in a memory (Datalogger).

The data stored can be printed (up to maximum 50 events). The

control unit features two levels of alarm: 1st level, pre-alarm. This

data is variable. The technician can modify pre-alarm intervention

for every sensor according to the type of plant to be controlled.

The level can be selected from 5% to 9% of L.E.L. or from 75 to 135

ppm. Main alarm is set from 10-20 % of L.E.L. or 150-300ppm. The

control unit is equipped with a main alarm relay which can be set

with or without Positive Safety Switch to enable further independent

control of a solenoid valve. Finally, the control unit allows the user to

control the actual operation of the sensors coupled.

SPECIFICATION

Power

Power Supply 230V (enclosure) 12VDC module

Secondary Battery (Not supplied) 12VDC ± 10% Max 2.2Ah

Battery Charger Charger Capacity 2.2Ah

Power Consumption 12V - 25W Maximum

230V - 30W Maximum

Relay Contact Range 10A resistive 230VAC, 5A 30VDC resistive

Alarm Settings

Pre-Alarm No.1 Can be set from 5% LEL (75ppm) to 9% LEL (135ppm)

Main Alarm 10-20% LEL / 150-300ppm

Sensor Fault Short circuit, interruption, sensor deterioration

Technical Specication

Dimensions Width 360mm |Height 320mm |Depth 135mm

Weight 260 grams

Display Illuminated digital display

Mounting Wall & Panel mounted

Input Signal 4-20mA

Device Precision 1% FS

Reaction Time <2 seconds

Working Temperature -10°C to 45°C

Start-up Self-Diagnostic Delay 90 seconds

Protective Rating IP65

Conguration

Positive Safety Yes (General functions menu)

Main Alarm Relay Actuation Yes (General functions menu)

Gas Type Selection Yes (Sensors menu)

Timed Sensor Test Facility Yes

Emergency Stop Connections Yes

O2Compatibility as Standard Yes (Sensors menu) - Increase/Depletion

Perhipheral Specication

No. of Remote sensors 8 sensors

Maximum Sensor distance 100m

Cable Diameter for sensors 1mm2CSA

(Screened and earthed at the controller end)

Compatibility

Sensor Compatibility All Duomo Sensors (Explosive, toxic gas and oxygen)

Approvals, Certications and Guarantee

Approvals EN 61010-1, EN 50270, EN 50271, EN 45544-3,

EN 60079-29-1, EN 50104

Guarantee 3 years as standard

8

Sensor

Conventional

8888

Illuminated

Digital Display

4-20mA

IP65