Megmeet MC200E Series Manual

1

MC200E Series PLC Main Module

Quick Start User Manual

Thank you for using Megmeet programmable logic controller (PLC).

Before using the MC200E series PLC product, please carefully read

this booklet so as to better understand it, fully use it, and ensure safety.

This quick start manual is to offer you a quick guide to the design,

installation, connection and maintenance of MC200E series PLC,

convenient for on-site reference.

This manual MC200E series for the following members: MC200E-

1616BTA

Version V1.0

Revision date July 26, 2010

BOM R33010006

For detailed product information, please refer to our MC200E Series

PLC User Manual, ControlStar Programming Software User Manual,

and MC100 /MC200 Series PLC Programming Manual. For ordering

the above user manuals, contact your Megmeet distributor or sales

office.

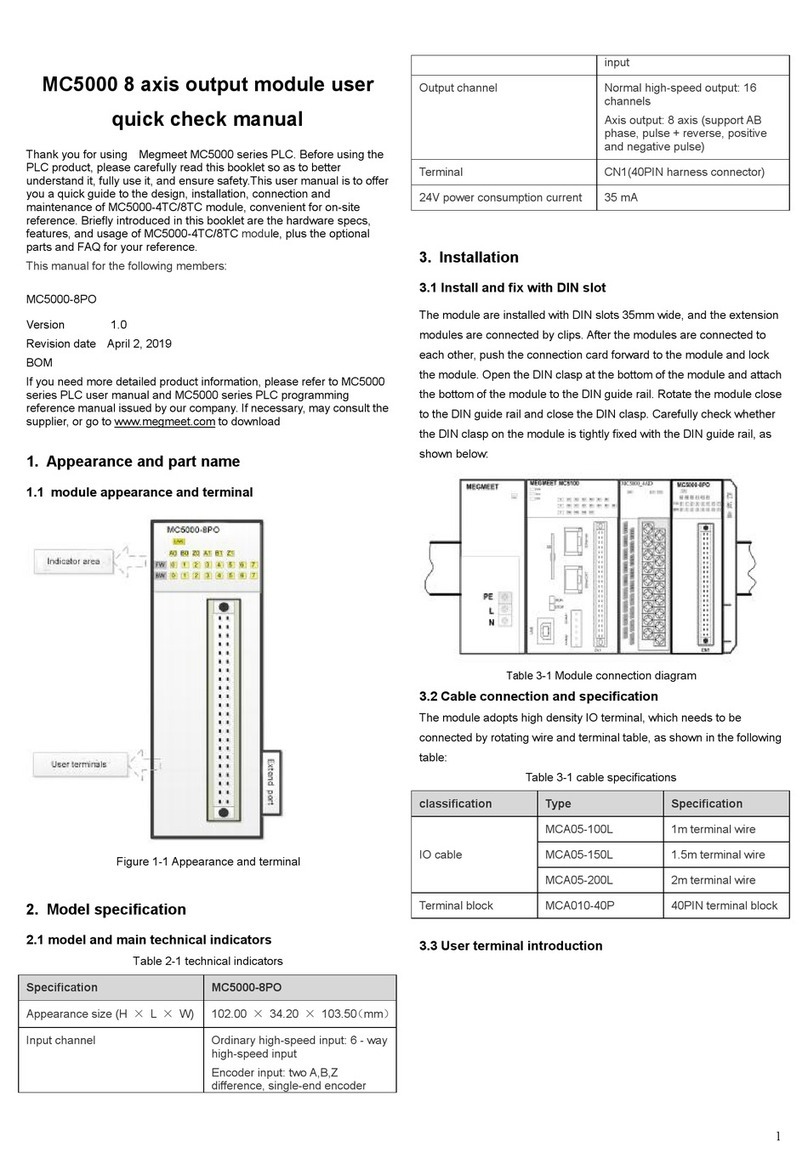

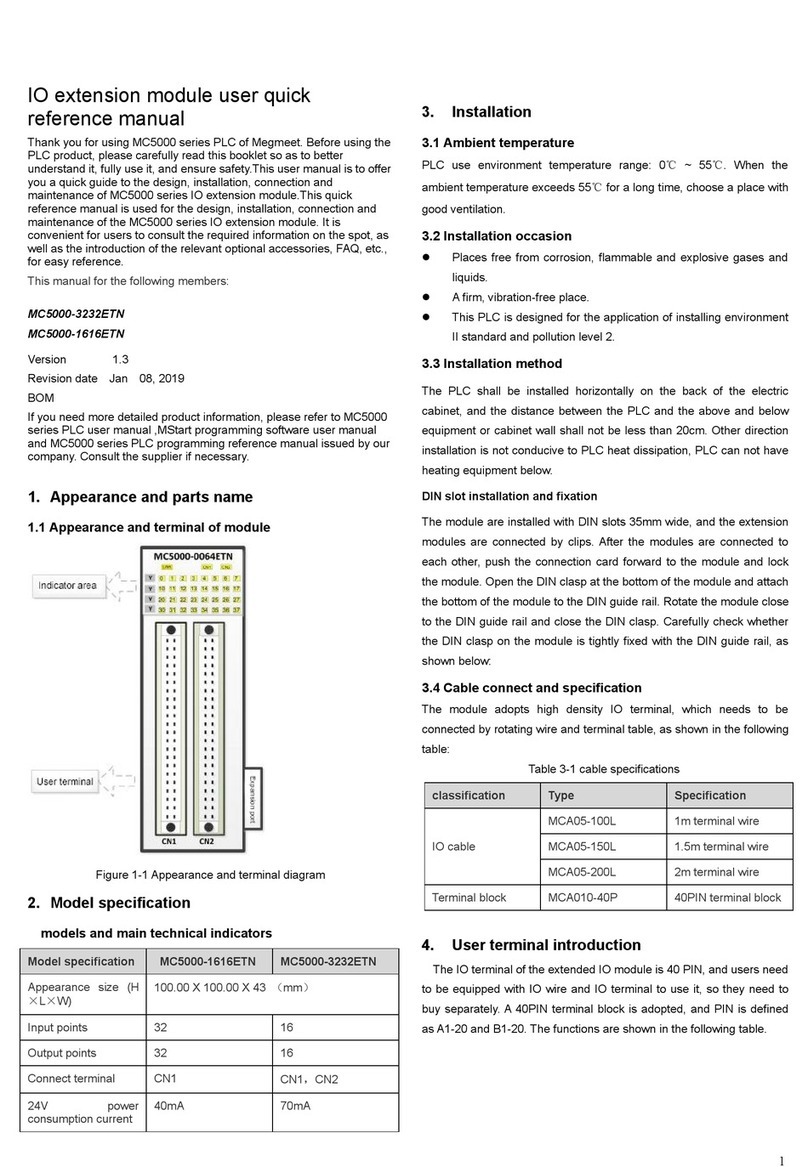

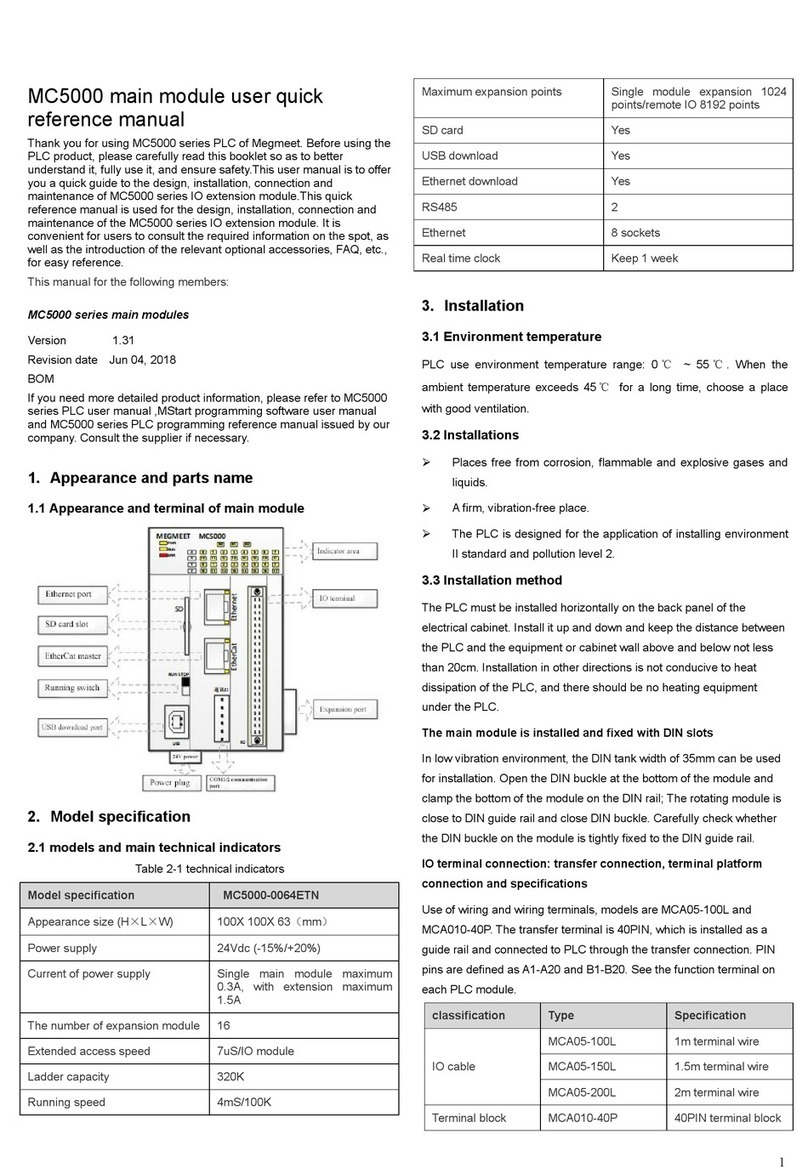

1. Appearance And Part Names

2.Module Description

MC

2

00

E -

16

16

B

T A

Special functions added

Start from 1 by time

sequence, like 1, 2, 3 and so on. When

empty, it implies no special function.

Power input mode (A: 220ac input; D:

24Vdc input); N: no external power

input.

Output mode. R: relay output; T:

transistor output; N: no output

Module type.

B: Basic module.

E: Extension module

Output points. In this example,16.

Input points. In this example,16.

Sub-version number, indicating functional

or structural change, changing by the order

of A, B, C

…

Z. When empty, it indicates

no sub-version change.

Version number.

Series number. 10: mini; 20: small;

30: mid; 40: large.

Megmeet Controller module

3.Installatin Location

3.1 Environmental Tempetature

PLC use ambient temperature range: -5℃~55℃. Ambient

temperature for a long time when over 55 ℃,Should choose a

well-ventilated place.

3.2 Installation Site

◆Non-corrosive, flammable gases and liquids place.

◆Strong vibration-free place.

◆This PLC for the installation environment design II standards,

pollution level 2 applications.

3.3 Installation Position

Mount the PLC onto the cabinet backboard horizontally. You must

provide a clearance of at least 20cm, both above and below the unit, for

proper cooling. Never mount them to the floor or ceiling of an enclosure

or other directions. See the following figure. No heat generating

equipment should be around the PLC.

3.4 Installation Methord

DIN rail mounting

Generally you can mount the PLC onto a 35mm-wide rail (DIN), Open

the module at the bottom of the DIN card buckled,The bottom of the

module onto the DIN rail;

Rotating module close to the DIN guide rail, Close the DIN card clasp;

Double-check the module and DIN rail snap on DIN is closely fixed, as

the following figure

Screw fixing

Fixing the PLC with screws can stand greater shock than DIN rail

mounting. Use M3 screws through the mounting holes on PLC

enclosure to fix the PLC onto the backboard of the electric cabinet, as

the following figure.

Main Module Size

3.5 Cable Connection And Specifications

Cable specifications

When wiring a PLC, use multi-strand copper wire and ready-made

insulated terminals to ensure the quality. The recommended model and

the cross-sectional area of the cable are shown in the following table.

Cable

Recommended Wire NO.

Conductor Cross-Section

AC power line(L、N)

AWG12、18

1.0~2.0mm²

Ground wire( )

AWG12

2.0mm²

Input signal wire(X)

AWG18、20

0.8~1.0mm²

Outout signal wire(Y)

AWG18、20

0.8~1.0mm²

Fix the prepared cable head onto the PLC terminals with screws.

Fastening torque: 0.5~0.8Nm.

◆In order to safety (to prevent electric shocks and fire accident) and

reduce noise, PLC grounding terminals should be in strict accordance

with the national electrical code requirements grounding, grounding

resistance should be less than 100 Ω. Multiple PLC ground, should be

single-point grounding, ground loops can not form. As below:

2

ERRO

RIGHT

4.Power Estination

MC200E main modules have an internal power supply module, give

priority to itself, the expansion module and other electric equipment

with power. The power performance index is as follows:

Project

Unit

Min

Rated

Max

Note

Input Voltage

Range

Vac

90

220

264

Normal operating range

and start machine

Input Current

A

/

/

1.5

90Vac Input ,Loaded

with output

MC200E Lord module provides 5 V dc logic power supply (5 V/GND)

and 24 V dc logic power supply (24 V/GND) for self and all extension

module. At the same time MC200E Lord module can also provide 24 V

dc power supply (24 V/COM), the 24 VDC can input point or other

equipment for power supply, MC200E series provide active I/O

extension module, the 5 V/GND, 24 V/GND, 24 V/COM output can be

used as the subsequent passive extension module of power supply.

Model

5V/GND

To provide the

maximum capacity

expansion module

24V/GND

To provide the

maximum capacity

expansion module

24V/COM

Offer capacity

to foreign

MC200E-1616BTA

525 mA

600mA

460 mA

*5 V/GND (24 V/GND) for the maximum capacity is refers to, When 24

V/GND (5 V/GND) no load, which can provide the maximum output

capacity.

5. Connect the power cord and grounding lines

MC200E communication power input module and auxiliary power

connection examples below:

COM

+24V

N

L

POWER

S/S

Y0

COM0

Y1

COM1

Y2

Y3

Y4

Y5

Y6

Y7

COM2

Y10

Y11

COM5

X0

X1

X2

X3

X4

X16

X17

MC280-1616BTA

X0

X1

X7

+24V

Y0

Y1

COM0

Y2

MC200-0808ER

AC - L

AC - N

+24V

+5V

GND

传感器

编码器

+24V

VGND

COM3

The AC power and auxiliary power connection examples

6.The User Terminals Introduction

MC200E-1616BTA Terminal definition

Pins

Identification

Fuction Declaration

L/N

220V AC power input,respectively firewire,zero line

Ground wire terminals PG

Pins

Identification

Fuction Declaration

+24V

Auxiliary DC power for users’ external equipment, work with

COM

COM

Negative pole of +24V auxiliary power

S/S

Input mode selection: sink mode when connected with +24V,

or source mode when connected with COM

●

Null, for isolation. Leave it suspended

X0~X17

Switching signal inputs, work with COM to generate input

signal

Y0、Y1、COM0

Control output

terminals, group 0

The COMx of different output

groups are isolated from each

other

Y2、Y3、COM1

Control output

terminals, group 1

Y4、Y5、COM2

Control output

terminals, group 2

Y6、Y7、COM3

Control output

terminals, group 3

Y10~Y13、

COM4

Control output

terminals, group 4

Y14~Y17、

COM5

Control output

terminals, group 5

7. Switch input and output characteristics

7.1 The switch quantity input X port specifications

Project

Specification

Signal Input Metherd

Source type/leak type way, the user can

choose through the S/S terminal.

Electrical

Specificatio

n

Detaction

Voltage

24Vdc

Input

Impedance

X0~X7 terminal:3.3kΩ。Other port 4.3kΩ

Input is

ON

External loop resistance is less than 400 Ω

Input is

OFF

External loop resistance is more than 24 kΩ

Filter

function

digital

filtering

X0 ~ X7 have digital filter function, filtering

time can be set by the user program

Hardwar

e filter

Input terminals other than X0 ~ X7 are

hardware filters. Filtering time is about 10ms

High-speed function

X0~X7: high-speed counting, interrupt, and

pulse catching .X0 ~X7 terminals are up to

10kHz Max.

Public terminal

S/S terminal,a public terminal

MC200E series PLC to provide a port "S/S", Used to select the input

signal is input source type way or leak type input methods.

The S/S terminals and + 24 V terminal connected, that is set to leak

type input methods, can connect NPN type sensor. Sink input

equivalent circuit of the internal and external wiring is shown below

Internal logic circuit work power

24

V

/

5

V

/

GND

24

V dc

auxiliary power

Sensor

+

24

V

COM

24V

+

24V

-

Logic

Control

Circuit

PLC

AC equivalent circuit inside the main module

S

/

S

X

0

X

1

X

2

Xn

Users can also input by source type to connect,

In this case, only the external switching power supply, you can connect

PNP sensors. Source-type input of the internal equivalent circuit and

external wiring as shown:

3

24

V

/

5

V

/

GND

Logic

Control

Circuit

PLC

AC equivalent circuit

inside the main module

S

/

S

X

0

X

2

Xn

24

Vdc

r

+

24

V

COM

24V

+

Sensor

External provide

24

Vdc

Power

24V

-

The I/O extension module internal equivalent sources and the input

signal wiring are shown below.

7.2 output characteristics and signal specifications

Output port specifications

Project

Transistor output port

External Power

5~24Vdc

Circuit isolation

PhotoCoupler

Operation indication

LED is on when optical coupler is driven

Leakage current of

open circuit

Less than 0.1mA/30Vdc

Minimum load

5mA(5~24Vdc)

Max.

output

current

Resistive

load

Y0~Y7:0.3A/1 point;Others:0.3A/1 point;0.8A/4

point;1.2A/6 point;1.6A/8 point

Inductive

load

7.2W/24VDC

Lamp

load

Y0~Y7:0.9W/24Vdc

Others:1.5W/24Vdc

Response

time

ON→OFF

Y0~Y7:Less than 5 us(Load current above 10 mA)

Others:Less than 0.5ms(Load current above 100 mA)

OFF→ON

Max output frequency

Y0~Y3:Each channel:200kHz;Y4~Y7:Each

channel:100kHz

Output common

terminal

Y0,Y1,COM0;Y2,Y3,COM1;Y4,Y5,COM2;

Y6,Y7,COM3;

Y10~Y13,COM4;Y14~Y17,COM5

Fuse protection

NO

8. Power operation and routine maintenance

8.1 Power operation

After the connection, item by item, check to ensure that no foreign

connections fall into the cabinet inside,heat flow

1.Switch on the POWER of the controller, POWER light should be light;

2.Start the PC software programming, Download the user program

will be programmed into the controller;

3.Download program calibration finished.

8.2 Routine Maintenance

Routine maintenance checking should pay attention to the following:

1.Ensure working environment clean and tidy, controller, avoid foreign

body in dust into machine;User equipment

2.To maintain good ventilation controller;

3.All wiring connections and terminals, fixed tightly in good condition

4. Observe the indicator light controller, observe LCD display screen

and state information.

9. The common problems and solutions

When the controller can not work normally, please check in turn:

1. Power line connection and protection of electrical switches and

related conditions, ensure controller has been reliable power supply;

2. The connection of user terminals is strong;

3. Refer to the fault record. If the above checks are done and when

confirmed controller still unable to work, Can refer to the table and

working status of the controller for analysis

Phenomenon

Possible cause

Solution

Power lights and other

lights are not bright

Power supply pressure loss

or voltage is too low

Check the power supply condition,

be ruled out

Disconnect the power

switch or fuse blown

Check the switch, wires or fuse

condition, be ruled out

Power wiring abnormal

Power board damage

Replace controller

POWER Lights

flashing

Power lines contact

undesirable

Check and make sure:1.24VL、24

VN terminal voltage whether

between the normal range; 2.

P24V and COM between

terminals whether short circuit or

load is too large

P24V/COM auxiliary

power output is circuit,

leading to the current limit

RUN indicator and

ALARM indicater are

not bright

Programme error

Confirm the power under normal

operation of the menu in controller

test

LCD can't display

properly

Power wiring undesirable,

or P24V/COM a short

circuit

Confirm the power under normal

operation of the menu in controller

test

Output cannot close

(OFF)

External connection is bad

Re-wiring,make sure the eiring is

correct.

Relay contacts damage

Frequency movement of relay port

can be swapped with the port idle.

Can't download,

upload, monitoring

Programme cable connect

bad

Use the special programming

cable of Megmeet controller

A serial port can't

control the other

equipment

Cable connection bad, or

connection error, such as

the signal attribute TXD

and RXD confusion

Will signal lines connected

correctly

Communication master

and slave feature is

inconsistent,such as baud

rate,parity,data

bits,address.

The communation parameter is set

to the same.

Communication protocol is

inconsistent with the

master and slave

Set the same communation

protocal.

Notice

1. The warranty range is confined to the PLC only.

2. Warranty period is 18 months, within which period Megmeet

Network Power conducts free maintenance and repairing to the PLC

that has any fault or damage under the normal operation conditions.

3. The start time of warranty period is the delivery date of the

product, of which the product SN is the sole basis of judgment. PLC

without a product SN shall be regarded as out of warranty.

4. Even within 18 months, maintenance will also be charged in the

following situations:

Damages incurred to the PLC due to mis-operations, which are

not in compliance with the User Manual;

Damages incurred to the PLC due to fire, flood, abnormal voltage,

etc;

Damages incurred to the PLC due to the improper use of PLC

functions.

5. The service fee will be charged according to the actual costs. If there

is any contract, the contract prevails.

4

6. Please keep this paper and show this paper to the maintenance unit

when the product needs to be repaired.

7. If you have any question, please contact the distributor or our

company directly.

Shenzhen Megmeet Control Technology Co.,Ltd

Address: 5th Floor,Block B,Ziguang Information Harbor, Langshan Rd,

Science& Technology Park, Nahshan District, Shenzhen

Homepage: www.megmeet.com

Copyright © 2011 by Shenzhen Megmeet Control Technology Co.,Ltd

All rights reserved. The contents in this document are subject to change

without notice.

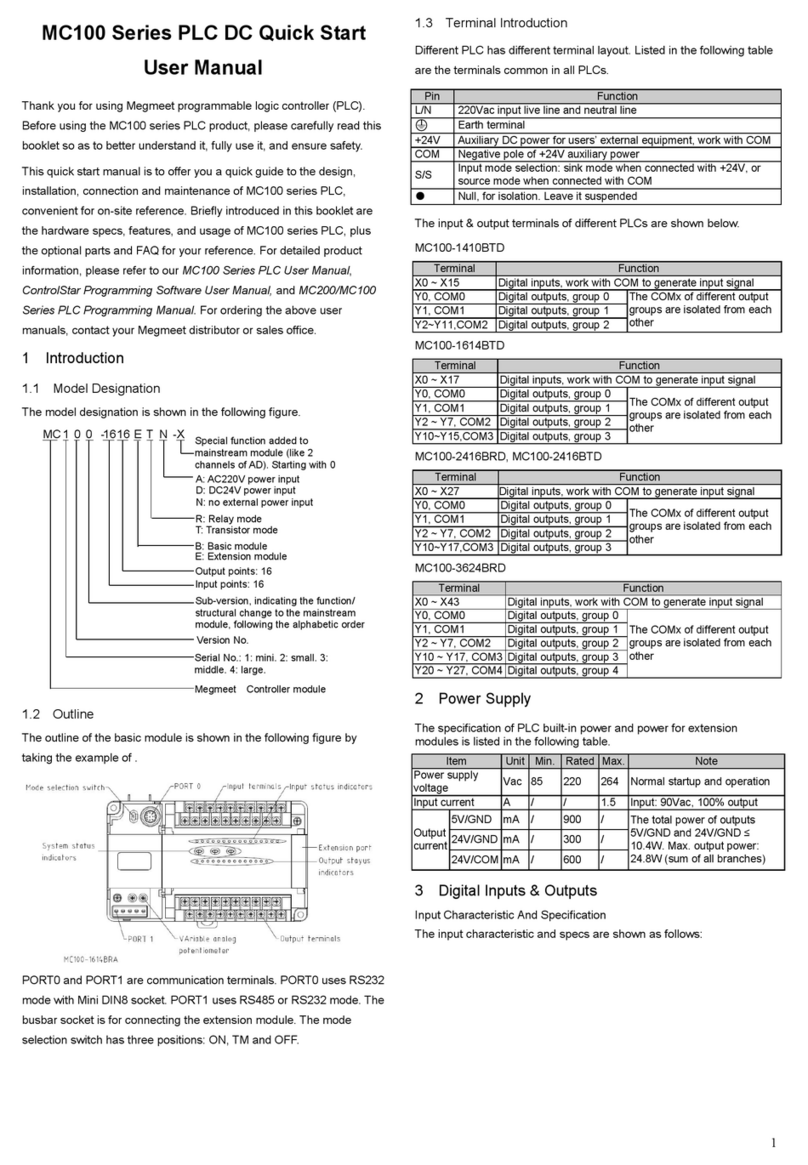

This manual suits for next models

1

Other Megmeet Controllers manuals

Megmeet

Megmeet L6 Series User manual

Megmeet

Megmeet MC5000 Series User manual

Megmeet

Megmeet MC100 Series User manual

Megmeet

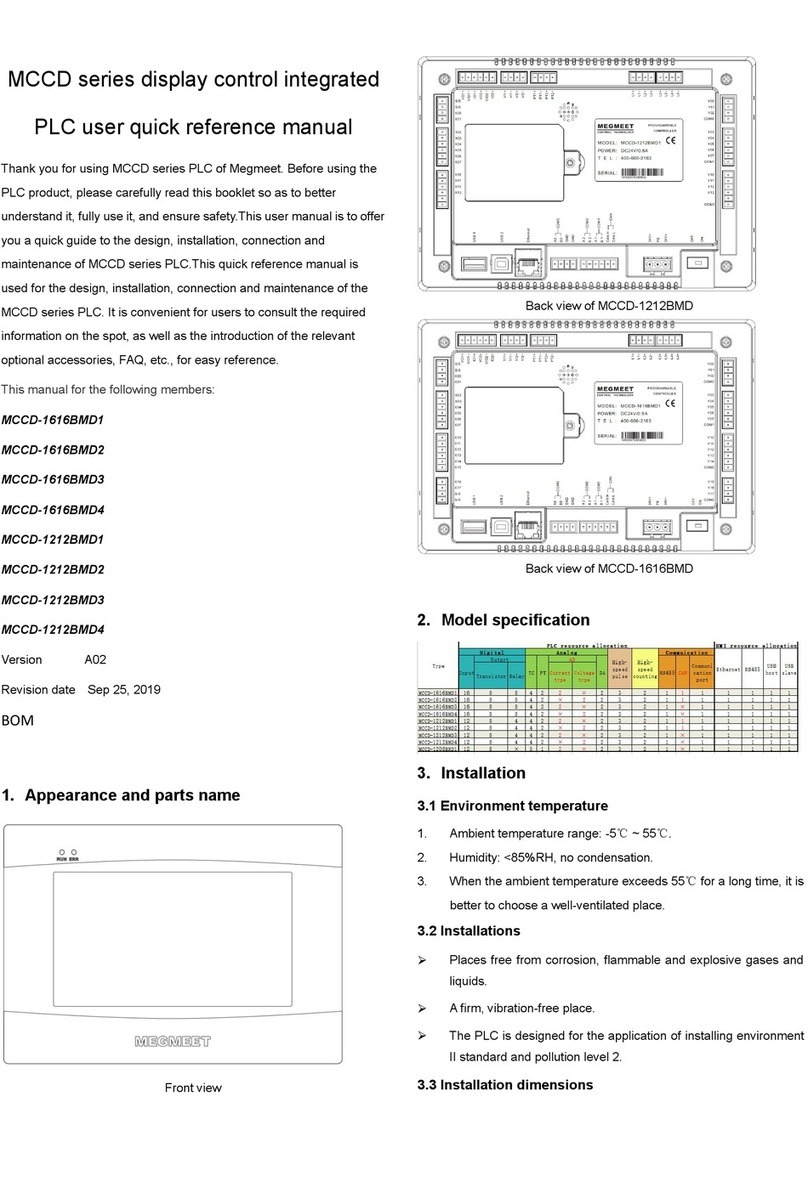

Megmeet MCCD Series Service manual

Megmeet

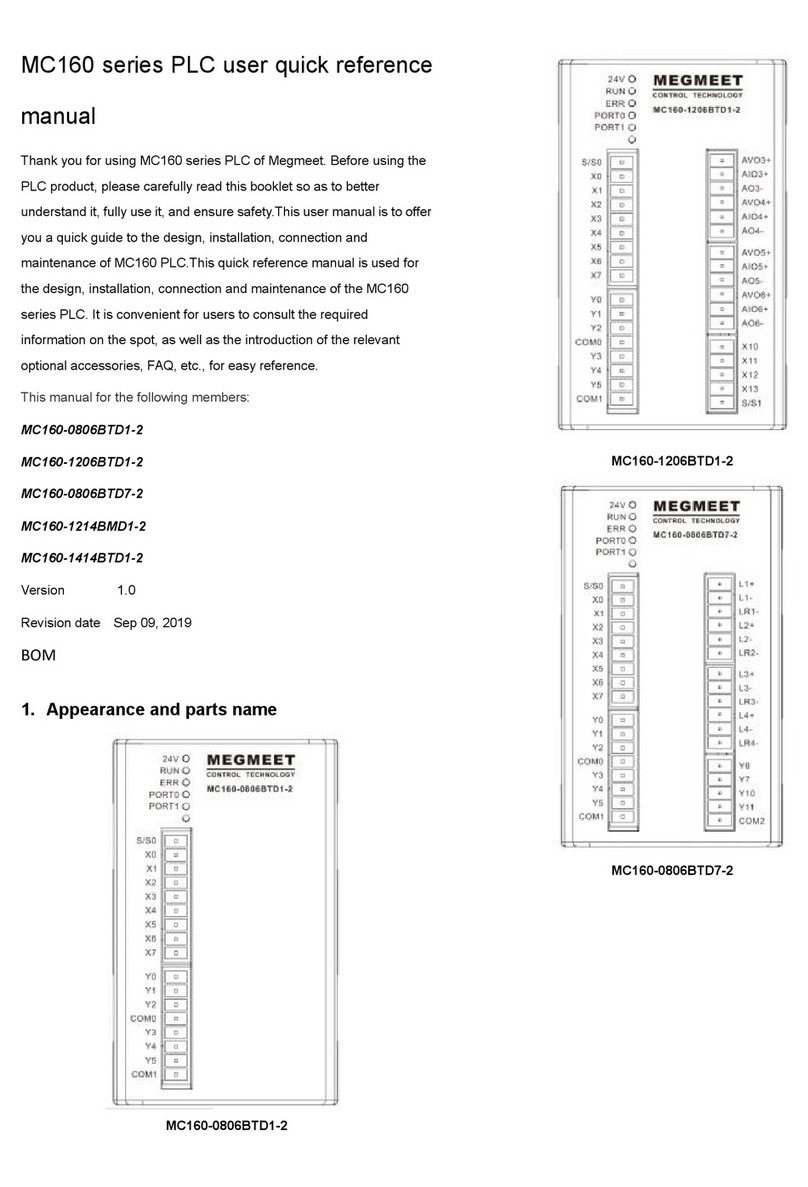

Megmeet MC160 PLC Series User manual

Megmeet

Megmeet MC5000 Series User manual

Megmeet

Megmeet MV820 User manual

Megmeet

Megmeet MC5000 Series User manual

Popular Controllers manuals by other brands

Remote Control

Remote Control RCEL005X instructions

Samson

Samson TROVIS 5177 Mounting and operating instructions

Brightlink

Brightlink BL-VW22-4K60-GUI user manual

Xantrex

Xantrex SOLAR CHARGE CONTROLLER 30 owner's guide

Edgewater Networks

Edgewater Networks EdgeMarc 250W Hardware installation guide

Omron

Omron SmartVision MX user guide