Instruction Manual

DHS-15 Spreader - V1.4 www.durapac.com Page 4 of 8

Never pressurise uncoupled couplers. Only use hydraulic equipment in a coupled

system

3.2 Hydraulic Hoses & Fluid Transmission Lines

Avoid short runs of straight line tubing. Straight line runs do not provide for

expansion and contraction due to pressure and/or temperature changes

Reduce stress in tube lines. Long tubing runs should be supported by brackets or

clips. Before operating the pump, connections should be tightened securely and

leak-free. Over tightening can cause premature thread failure or high pressure

fittings to burst

Should a hydraulic hose ever rupture, burst or need to be disconnected,

immediately shut off the pump and release all pressure. Never attempt to grasp a

leaking pressurised hose with your hands. The force of escaping hydraulic fluid can

inflict injury

Do NOT subject the hose to potential hazard such as fire, sharp objects, extreme

heat or cold or heavy impact

Do NOT allow the hose to kink, twist, curl, crush, cut or bend so tightly that the fluid

flow within the hose is blocked or reduced. Periodically inspect the hose for wear

Hose material and coupler seals must be compatible with the hydraulic fluid used.

Hoses also must not come in contact with corrosive materials such as battery acid,

creosote-impregnated objects and wet paint. Never paint a coupler or hose

FAILURE TO HEED THESE WARNINGS MAY RESULT IN PERSONAL INJURY AS WELL AS PROPERTY DAMAGE.

4.0 Installation

IMPORTANT: Always secure threaded port connections with high grade, non-hardening pipe

thread sealant. Teflon tape can be used if only one layer of tape is used and it is applied

carefully, two threads back, to prevent the tape from being introduced into hydraulic system,

which could cause jamming of precision-fit parts

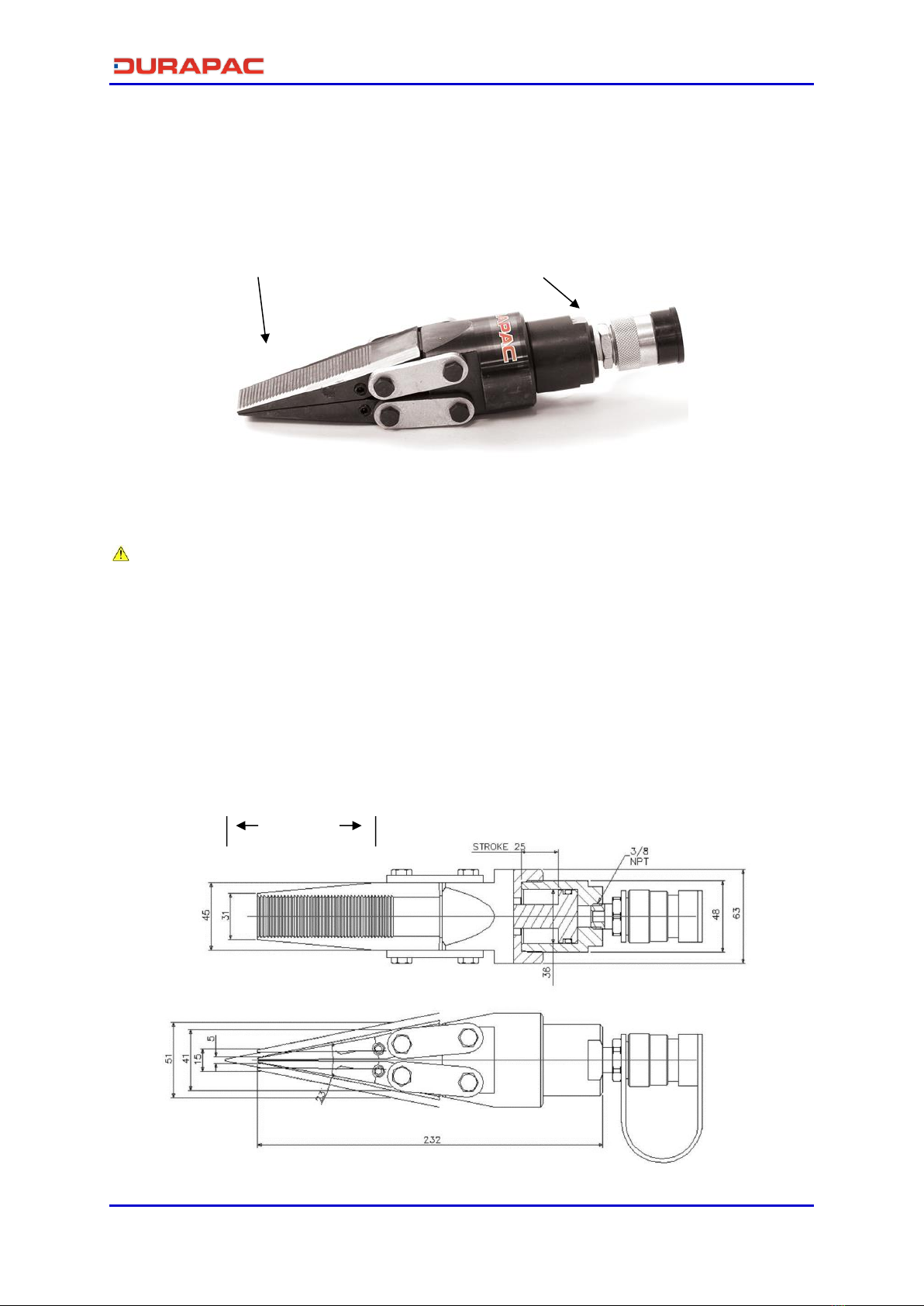

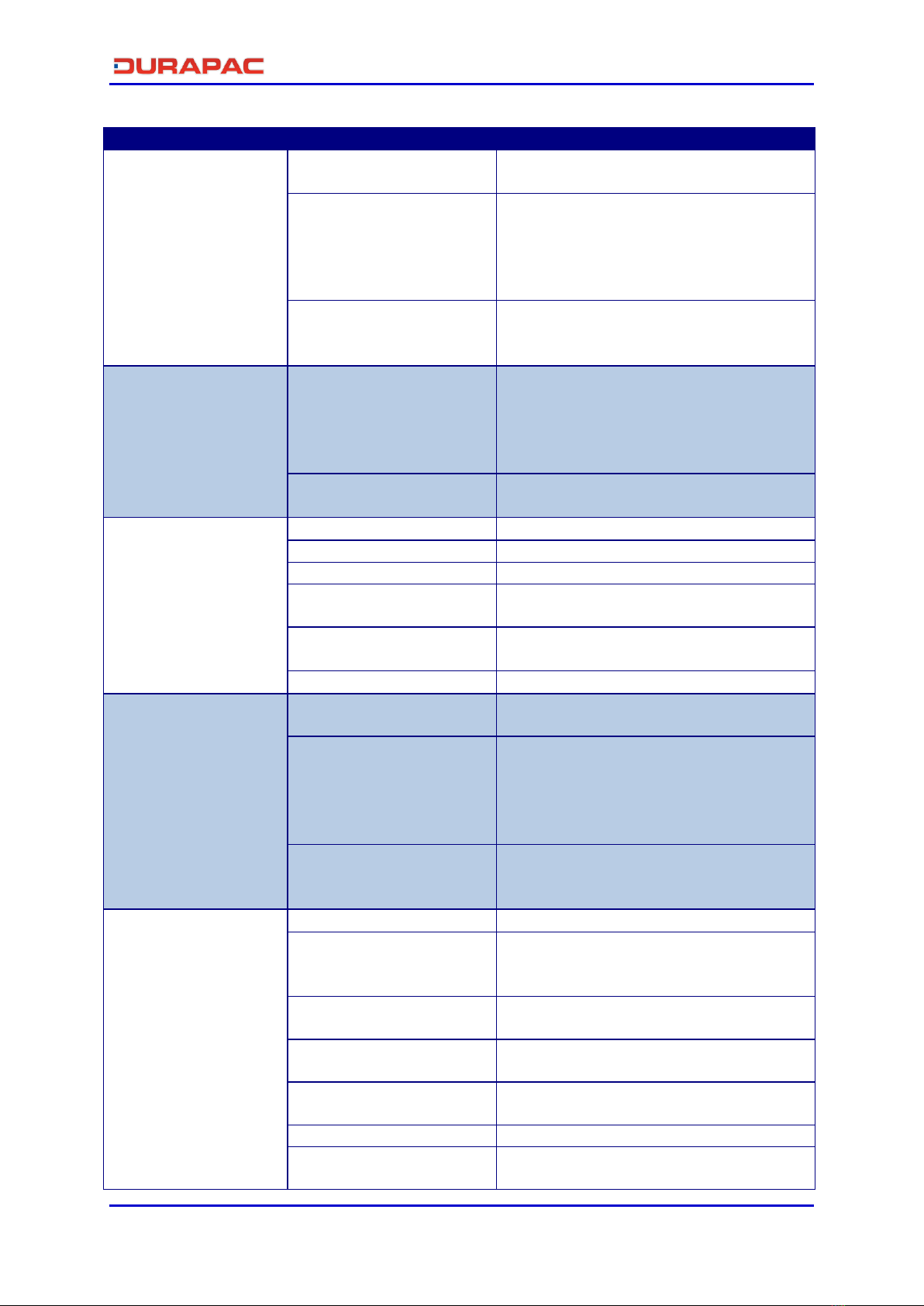

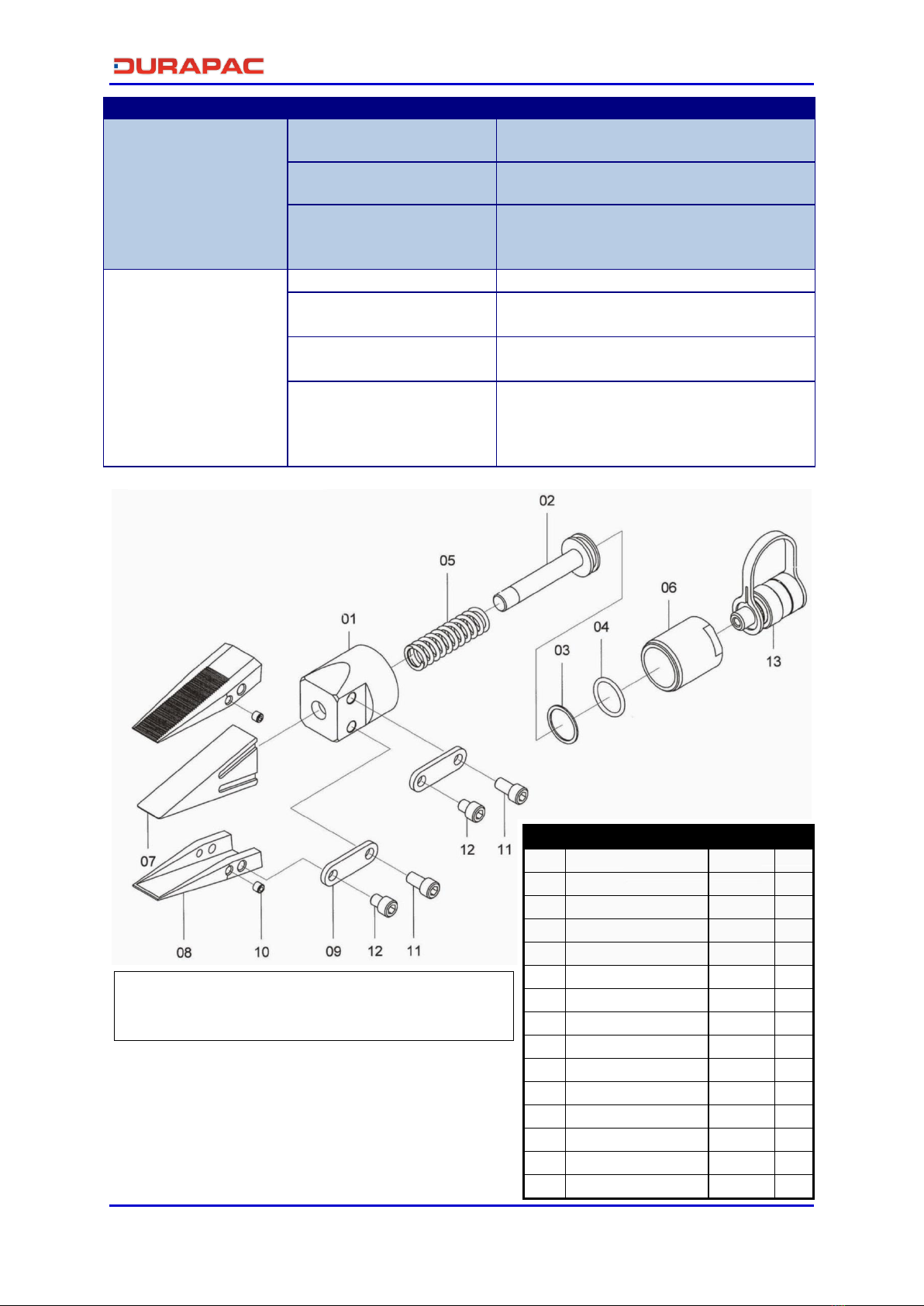

4.1 Familiarise yourself with the specifications and illustrations in this owner’s manual.

Know your spreader, its limitations and how it operates before attempting to use. Refer

to the specification chart below or if in doubt, contact a Durapac representative.

4.2 Make hydraulic connections; use a pump release valve or a 3-way valve and one hose

for single-acting cylinder.

IMPORTANT: Fully hand-tighten all couplers. Loose coupler connections will

block the flow of oil between the pump and the cylinder

4.3 Check all system fittings and connections to be sure they are tight and leak free.