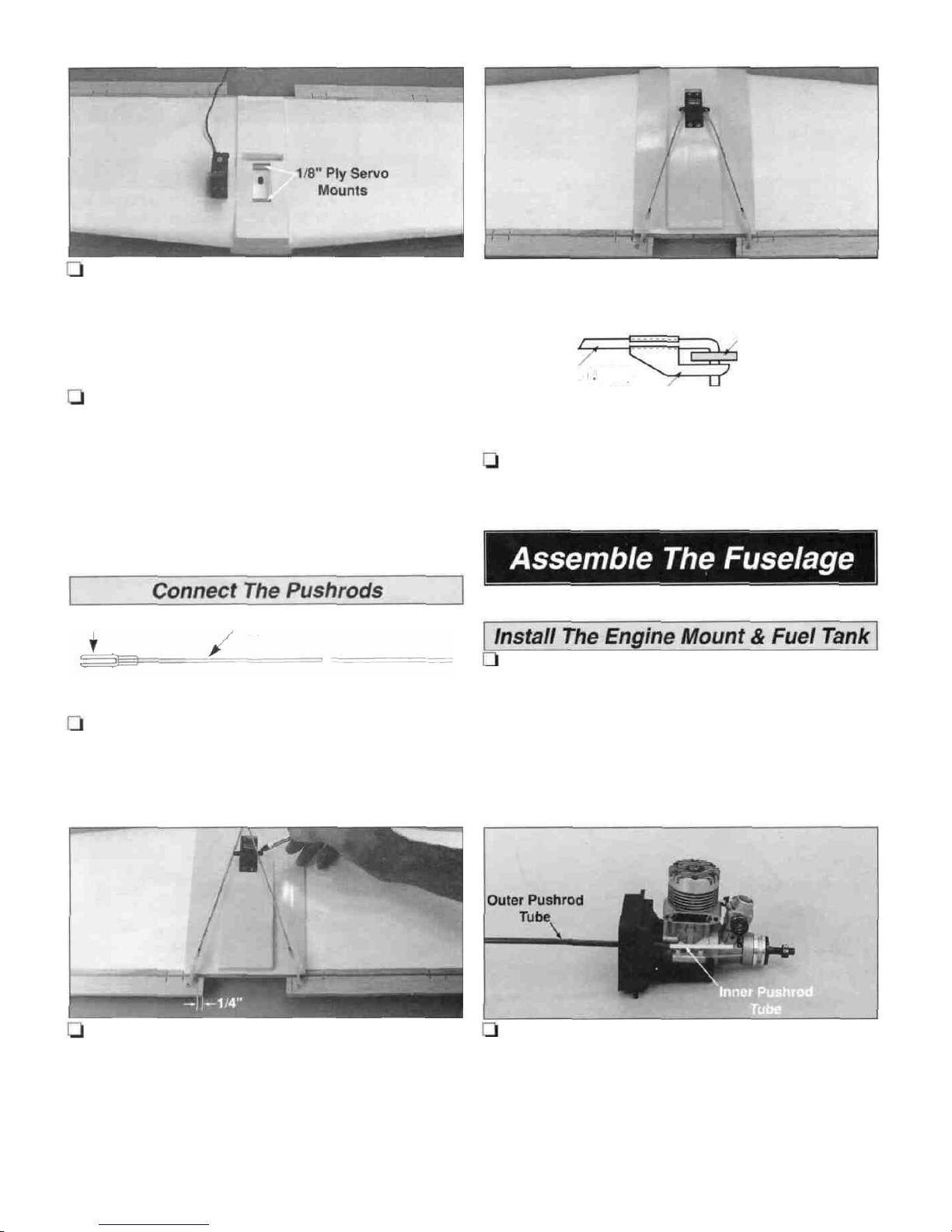

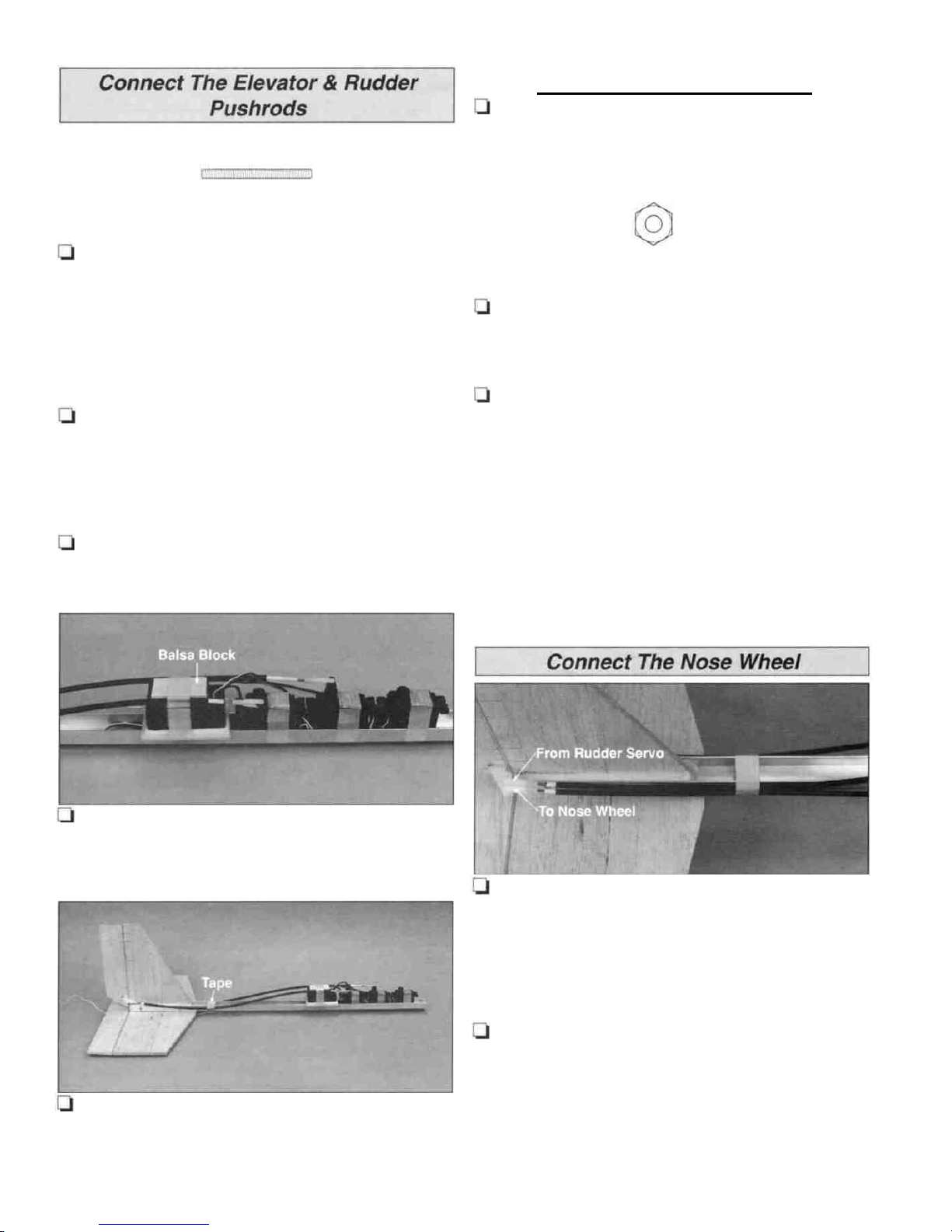

3Cut the inner pushrod tube to the correct lengththen

install the last 1" threaded stud with a clevis Position the

steering arm as shown inthe photo Adjust the length of

the pushrod so thatwhen the rudder is neutraland the

pushrod isconnected to the steering arm, the nose wheel

isalsoneutral.

1Disconnect the elevator and rudder pushrods from

the tailfeathersRemove the control horns and hinges.

Then takethe stabilizerand finoffthe fuselage channel

Use a sanding block and 150-grit sand paper to round the

leading edges of the finand stabilizer Final sand all the tail

surfaces with 320-grit sandpaper Tip: If you don't mind a

little extraworkand would like to have a better looking

model witha 'finished" appearance, taper the rudder and

elevatorby sanding the trailingedges to a thicknessof

approximately 3/32' This is optional anddoes notaffect

the flight performance of the Aerobat.

4Turn the modelover and confirm the coordination of 2While the ailerons are stillconnected, sand the tips of

the rudder and the nose wheel - when the rudder moves

left,the nose wheel should turn left. the wing so the balsa trailingedge and ailerons are all flush

with the wingtip Disconnect the pushrods and remove the

control horns fromthe aileronsDetach the ailerons from

the wing and remove the hinges

3Apply white HobbicoHobbyLite" filler to any dentsin

the foam wing Afterthe fillerhas hardened, use a sanding

block and 220-grit sandpaper to remove irregularities and

the seam on the leading edge For the best appearance, it

isrecommended that finalsanding bedone with320-grit

sandpaper but withouta sanding block Tip: Aswith the

rudder and elevator, for a "finished" appearance, you may

taper the ailerons

We presume that the Aerobat will bebuilt byexperienced

modelers but due toitssimplerapidconstruction,the

Aerobat may appeal to less experiencedmodelers as well

Fornewmodelersorthoseunfamiliarwithfinishing

techniques,wehave providedsome basic information

aboutthecoveringmaterialsavailableandthe

recommended covering sequence.

Thefoamwingand thebalsasurfaces,includingthe

aileronsandtailfeathers,mustbe coveredwitha

protective,fuelprooffinishAmongthemanymodel

airplane covering materials available Top Flite EconoKote

film isrecommended EconoKote filmrequires a lower heat

range to apply than other iron-on films, so itcan beapplied

over the foam wing Itcan also beapplied to the wood tail

surfaces as well Apply EconoKote film with a hobby heat

seal iron.

Onesix-footroll will beenough to coverthe Aerobat,but if

you wish to add trim colors or other designs, you will have

to purchase more than just one roll

4Before covering, remove as much balsa and foam

dust as possible leftfromsanding the model This can be

done with compressed air,a vacuum cleaner, a brush or a

tack cloth.

Now the Aerobat 40 wing and tail feathers are ready

for covering

Carefully follow theinstructionsincludedwiththecoveringyou

haveselected

10