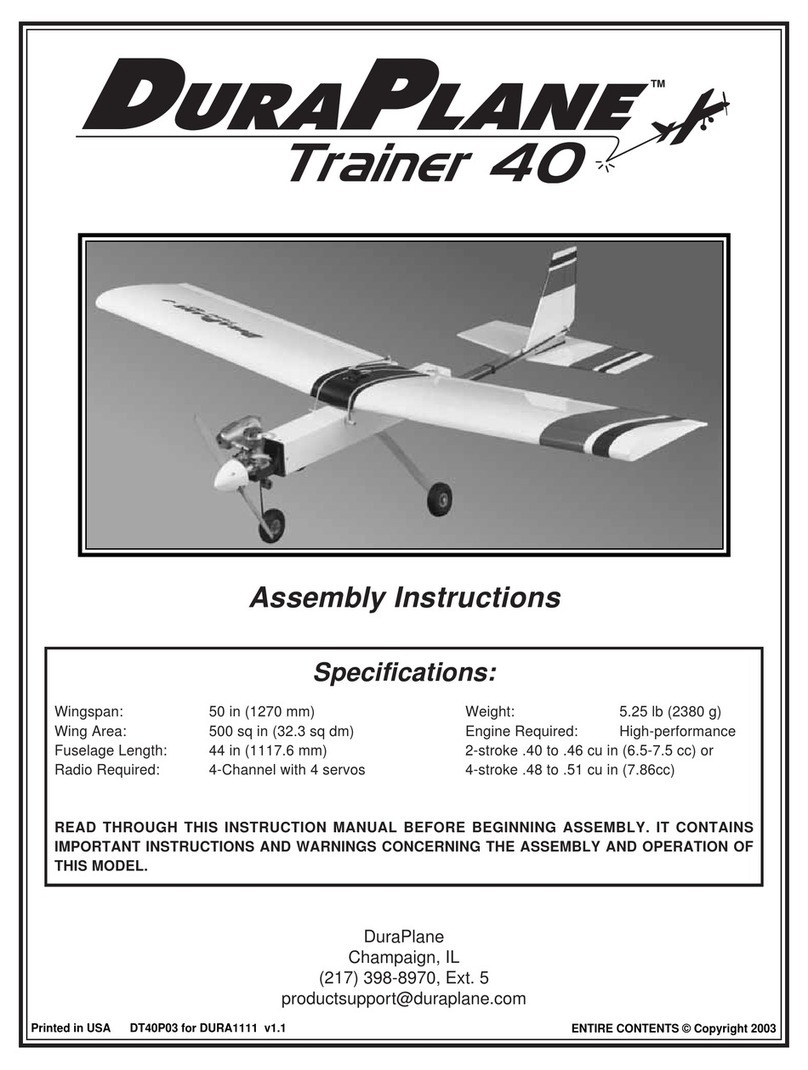

Thank you for purchasing the DuraPlane DuraStik 40 The

DuraStik 40 is the thirdgeneration of DuraPlane models

specificallydesignedforaerobaticflightThestick

configuration isreminiscent of the popular Great Planes stik""

series and isa perfect subject fora fastbuilding aerobatic,

fun flying DuraPlane model Because the DuraStik 40 isfully

aerobatic featuring a wing that has nodihedral (and does not

possess the self-righting characteristics found ina trainer), it

isrecommended that you donotattempt to fly the DuraStik

40asyour first model.

Ifthis isyour first model, the best way to learn to flyR/C is

to joina flyingclub The Academy of Model Aeronautics is

thenationalorganizationthatchartersmodelclubs,

sanctions competitions, and insures flyingfieldsacross the

United States We urge you to jointhe AMA Membership

willbringyouflyinginsurance,a subscriptiontoModel

Aviation Magazine, and many other benefits The AMA will

gladly send you membership information and lists of AMA

chartered clubs inyour area where you can seek the help

of experienced modelers.

Academy of ModelAeronautics

5151 East Memorial Drive

Muncie, Indiana 47302-9252

(800) 435-9262

FAX (765) 741-0057

Web Site:HTTP.//WWW.MODELAIRCRAFT.ORG

Your hobby shop isalso an invaluable place forservice,

partsand informationthatyourequireWe urgeyouto

patronize your local hobby dealer - hes thereto help you

enjoy your hobby.

#11Blades(HCAR0311, 100qty.)

Razor Plane (MASR1510)

Standard and Phillips screwdrivers

Needle nose pliers

Electric drill

Drill Bits 1/16", 3/32", 7/64", 1/8",5/32",

#19 (or 11/64"), 3/16", 15/64" (or 1/4")

X-Acto Building Square (XACR7726)

Kyosho Lexan Curved Scissors (KYOR1010)

Masking Tape

Waxed paper

TopFliteSealing Iron (TOPR2100)

Top Flite "HotSock"(TOPR2175)

Easy-Touch"BarSanders"

Great PlanesC G Machine (GPMR2400)

*A flat,durable, easy to handle sanding toolis a necessity

forbuilding a wellfinished model Great Planes makes a

completerangeof Easy-TouchBar Sanders(patent

pending) and replaceable Easy-Touch Adhesive-Backed

Sandpaper While building the DuraStik, we used a 5-1/2"

BarSander and an11" BarSander equipped with 80-grit

and150-grit Adhesive-backed Sandpaper.

This instruction manualprovides step-by-step instructions for

assembling the DuraStik 40 kit Assembly of the DuraStik 40

consists of six majorsteps,completed inthe following order

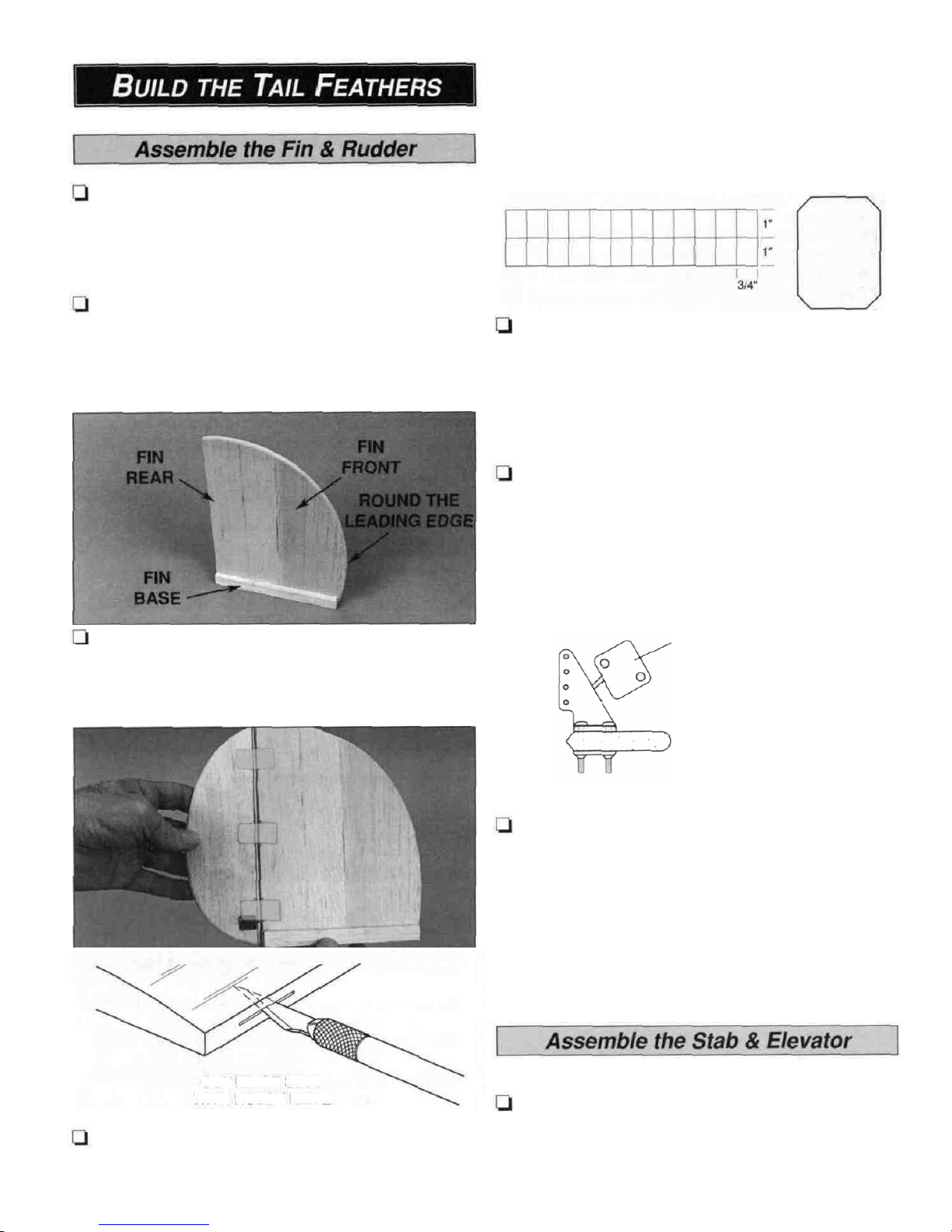

BUILDTHETAIL FEATHERS..................................4

ASSEMBLE THE FUSELAGE...................................6

RADIO INSTALLATION

............................................9

BUILD

THE

WING

...................................................12

COVER THE WING AND TAIL................................15

FINAL ASSEMBLY..................................................17

FLIGHT....................................................................19

Here's the complete listof Easy-Touch BarSanders and

Adhesive BackedSandpaper.

5-1/2" Bar Sander (GPMR6169)

11" BarSander (GPMR6170)

22" Bar Sander (GPMR6172)

33" BarSander (GPMR6174)

44"BarSander (GPMR6176)

Adhesive-backed 12' roll of:

80-grit (GPMR6180)

150-grit (GPMR6183)

180-grit (GPMR6184)

220-grit (GPMR6185)

Assortment pack of 5-1/2" strips (GPMR6189)

We use3M 320-grit wet-or-dry sandpaperfor finish sanding.

2