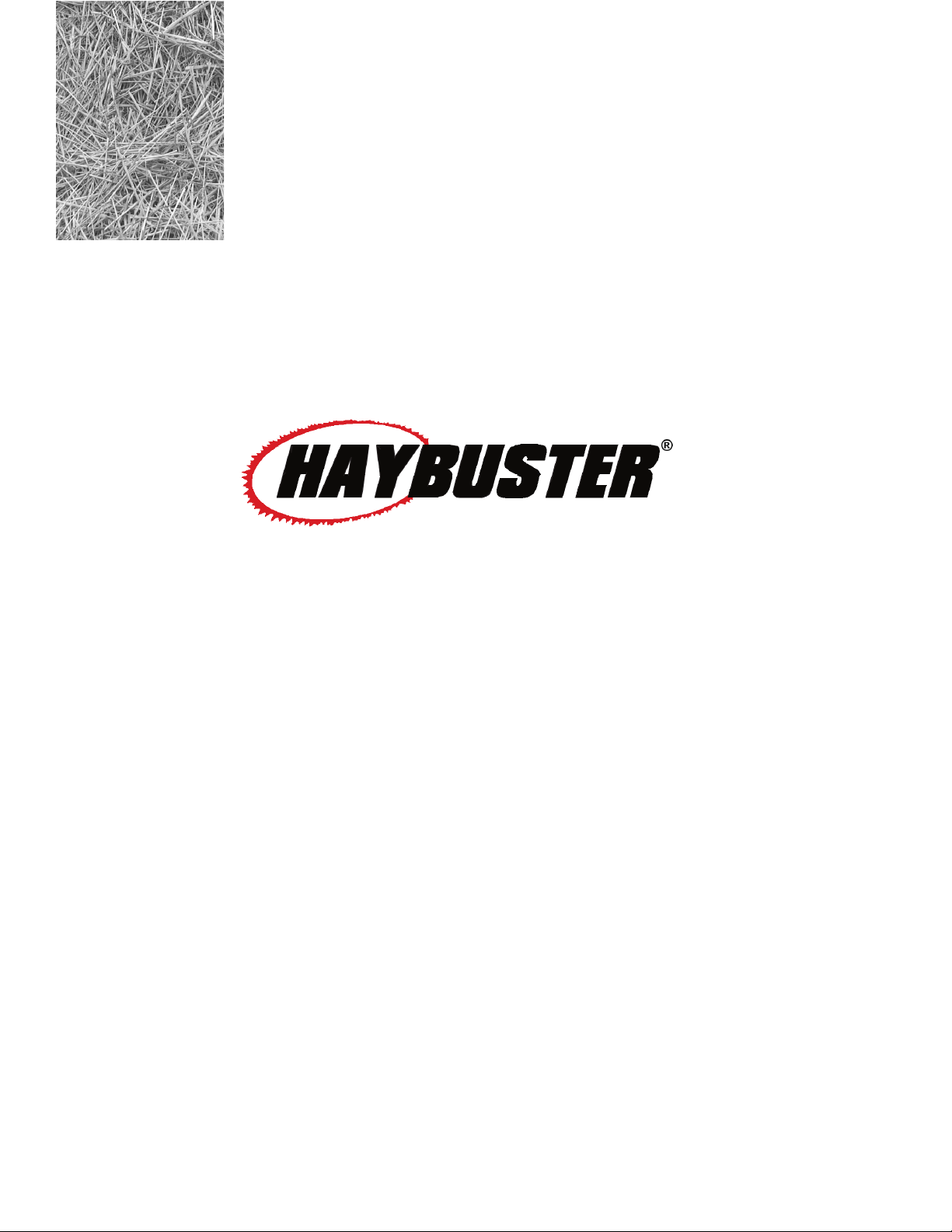

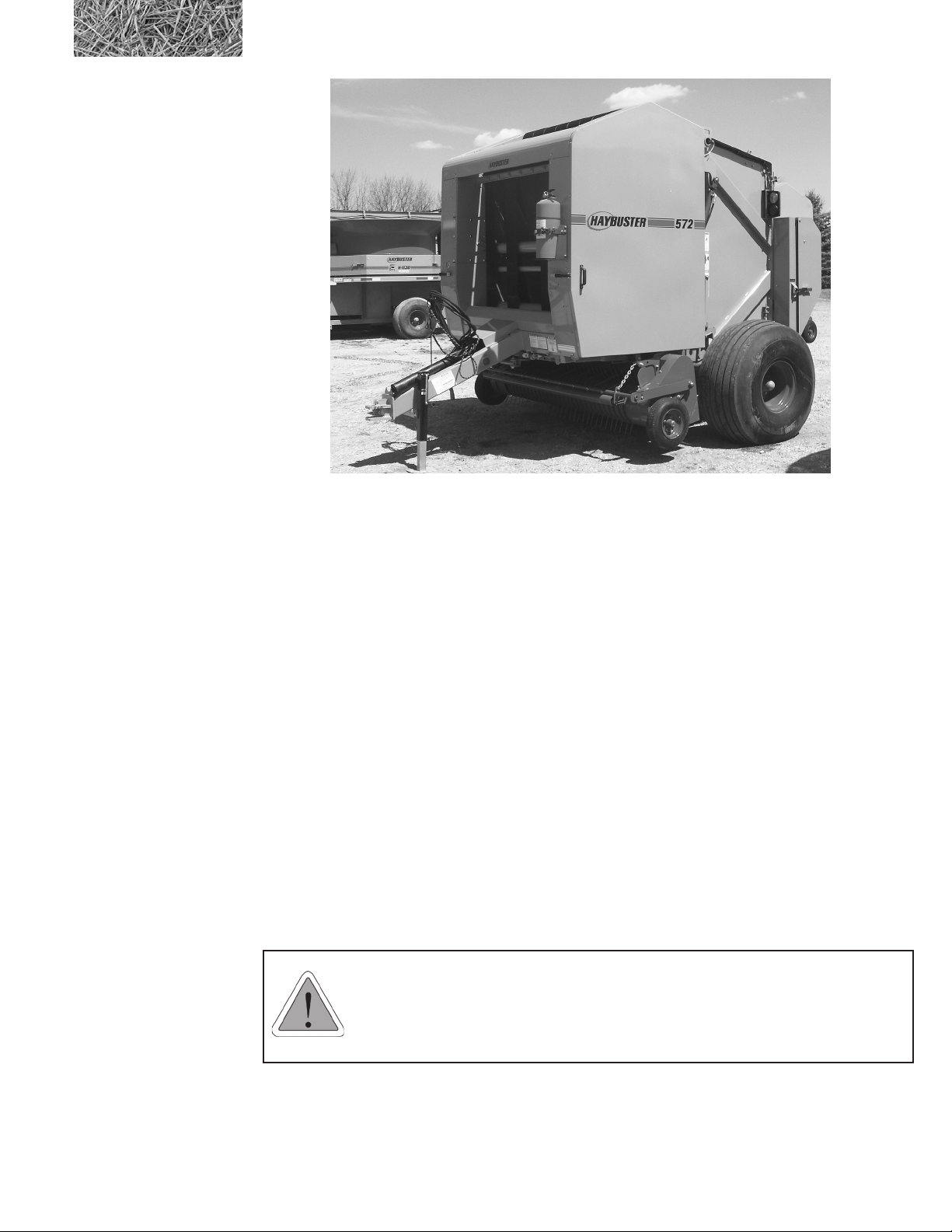

iv 572 ROUND BALER OPERATING INSTRUCTIONS

TABLE OF CONTENTS

Section 4: Baler Adjustment..................................................... 24

4.1 Bale Density Gauge ....................................................................................... 24

4.2 Adjusting Bale Density.................................................................................. 24

4.3 Adjusting twine tension................................................................................. 25

4.4 Adjusting gauge wheels................................................................................. 25

4.5 Gate Locking Procedure............................................................................... 26

4.6 Adjusting Compression Rack....................................................................... 26

4.7 Adjusting Main Drive Chain Tension.......................................................... 27

4.8 Adjusting pickup drive chain ....................................................................... 27

4.9 Adjusting belt tracking ................................................................................. 28

4.10 Adjusting pickup oat................................................................................. 28

4.11 Material Trap Cleanout and Inspection .................................................... 29

4.13 Belt and Lacing Pin Inspection .................................................................. 29

4.12 Secondary Drive Chain Adjustment.......................................................... 29

4.14 Belt Installation and Routing ..................................................................... 30

4.15 Twine Pincher Adjustment ......................................................................... 31

Section 5: Monitor..................................................................... 32

5.1 Monitor Operation ........................................................................................ 32

5.1.1 Bale Monitor Screen ....................................................................... 32

5.1.2 General Layout of controller ........................................................... 32

5.2 Calibration of the 572 Baler – General ....................................................... 33

5.3 Other Diagnosis .............................................................................................. 35

5.4 Menu Screen ................................................................................................. 36

5.4.1 Misc. Setup Screen........................................................................... 36

5.4.2 Twine setup values .......................................................................... 36

5.4.3 Net wrap setup values ..................................................................... 36

5.4.4 Misc Setup Screen........................................................................... 37

5.4.5%FullDenition............................................................................. 37

5.4.6AutoStartDelaydenition.............................................................. 37

5.4.7 Start Wrap/Wrap Reset Functions ................................................... 37

5.4.8 Twine Dispensing Indicators........................................................... 38

5.4.9 Twine Arms Position Indicator........................................................ 38

5.4.10 Auto Dump Feature ....................................................................... 38

5.4.11 Faults Screen ................................................................................. 38

5.4.12 Bale History .................................................................................. 38

5.4.13 Baling sequence ............................................................................ 39

5.4.14 Tying Sequence ............................................................................. 39

Section 6: Lubrication............................................................... 40

6.1 Lubrication .................................................................................................... 40

6.2 Chain Oiler .................................................................................................... 47