5

CHIMNEY DIAMETER

Follow the replace manufacturer’s manual

to determine required chimney diameter and

clearances between combustible materials

and your replace. Never use a chimney

with an inside diameter smaller than your

ue opening above rebox unless specically

allowed by the replace manufacturer. If you

are connecting to a masonry replace, refer to

Table 2 (pg 11) for proper sizing. To calculate

the chimney’s outside diameter, add 3 inches

to the inside diameter.

CHIMNEY HEIGHT

The National Fire ProtectionAssociation

Standard #211 states: “Chimneys shall extend at

least three feet above the highest point where it

passes through the roof of a building, and at least

two feet higher than any portion of a building

within ten feet.” (Fig. 1). Due to the overlap of

the joints, subtract1 inchfromeach Chimney

Section’s height to calculate installed height.

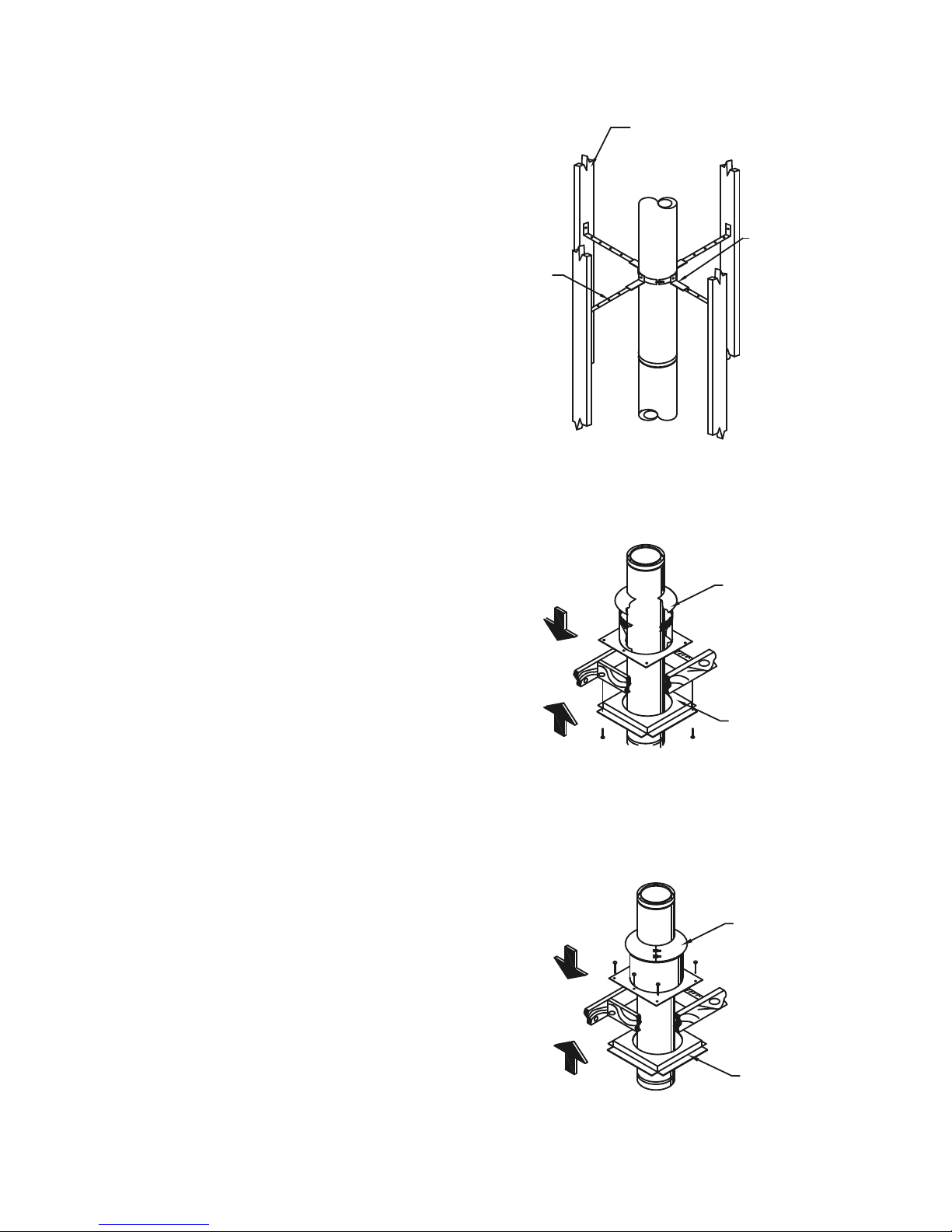

CHIMNEY ENCLOSURE

REQUIREMENTS

Through Rooms: Interior chimneys shall

be enclosed where they extend through

closets, storage areas, occupied spaces, or

anywhere where the surface of the chimney

could be contacted by persons or combustible

materials (including insulation). The air space

between the outer wall of the chimney and the

enclosure shall be at least 2 inches

Multi-Story: Consult local building code

ofcials for requirements in your area. The

National Fire ProtectionAssociation Standard

#211 states: “Factory-built chimneys that

pass through oors of buildings requiring

the protection of vertical openings shall be

enclosed with approved walls having a re

resistance rating of not less than one hour

when such chimneys are located in a building

less than 4 stories in height, and not less than

2 hours when such chimneys are located in a

building more than 4 stories in height.”

In Canada, except in single-family and two-

family dwellings, chimneys which extend

through another story must have an enclosure

with a re resistance rating equal to or greater

than that of the oor or roof assembly through

which they pass.

Cold Climates: In cold climates, chimneys

mounted on an outside wall should be

enclosed in a chase. Exterior chases reduce

condensation and creosote formation, and

enhance draft.Always maintain a 2” air-space

clearance to combustibles.

FIREPLACE RECOMMENDATIONS

Always follow the replace manufacturer’s

installationinstructions.

Installation: Install your replace as described

by the replace manufacturer. Be sure to

maintain all required clearances.

Flues: Connect only one replace per chimney.

Operation: Follow the replace safety manual

for maximum efciency and safety. Do not over

re. Any damage to the replace or chimney can

possibly voidyourwarranties.

Fuels: Donotburndriftwood, plastic,or

chemicallytreatedwoodsuchasrailroadties.

They are corrosive to your chimney system.

Follow the replace manufacturer’s instructions

regarding fuels.