2© durlum GmbH | www.durlum.com | Subject to changes of dimensions and design. Errors reserved. All rights reserved. | Issued: 08.11.2016

GENERAL INFORMATION

This assembly manual addresses all metal

ceilings manufactured by durlum. The dif-

ferent sections describe the related/rel-

evant products.

durlum is a leading German manufacturer

of metal ceilings and cladding elements,

mainly made of galvanised sheet steel,

aluminium and expanded metal.

The relevant products are described in the

marketing and sales documents. They are

both acoustically effective, and can also

be used as design elements only. Specifi-

cally, these products are:

• Acoustic ceilings

• Chilled ceilings

• CHARACTER products

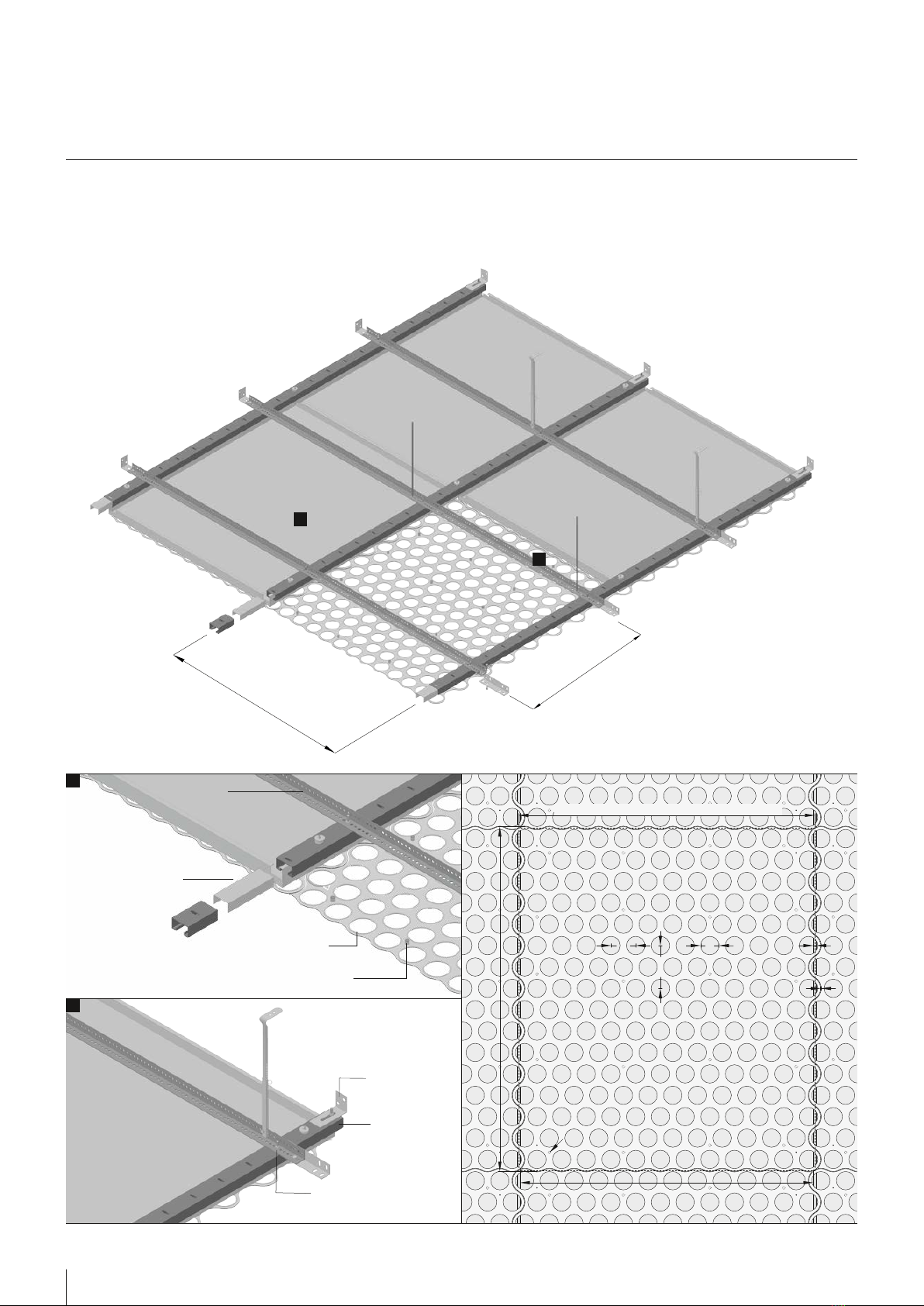

durlum differentiates between a wide

range of ceiling systems, for example S1.

“S1” stands for system 1 clamping. In this

system, there are different nomenclatures

that allow a further subdivision of the sys-

tems.

All durlum systems are systems of modular

design. This applies not only to the sub-

structure but also the ceiling parts that are

suspended, locked into place or placed

on the substructure.

durlum metal ceilings comply with the

standard EN 13964:2007 and are CE-cer-

tified.

Appropriate static certificates are avail-

able for special systems marketed by us

and for which no general approvals are

available, and appropriate designs com-

pliant with EN13964 have been construct-

ed. durlum lamps comply with standard

EN60598-1 and are CE-certified.

GUIDELINES

These installation instructions have been

structured in accordance with the require-

ment of EN 13964:2007 and describe a

proper assembly.

The description does not exempt the user

from examining the structural conditions,

implementing the building code regula-

tions and observing the information given

in the building permit prior to starting as-

sembly. They have priority, but could not

be included here.

It is advisable always to draw up assembly

diagrams/drawings, to establish the loca-

tion where assembly is to begin and to es-

tablish the required suspension points for

the relevant ceiling system prior to starting

assembly.

STRUCTURAL PRECONDITIONS

Metal ceilings may usually be installed as

soon as the building is swept clean, but

at least when all wet work in the interior

has been completed and the building has

been closed.

Prior to starting assembly, the suspension

points must be checked for their usabil-

ity, and load introduction into the building

must be guaranteed.

When using wall mounting points, such as

brackets or wall anchors, the load-carrying

capacity of the wall in question must be

checked.

If ceiling elements rest on brackets, pos-

sible wall movements must be taken into

account.

Only anchors for which a general building

supervisory approval is available may be

used, and their minimum extraction force

must be greater than 100 kg. The anchors

must be mounted as specified by the

relevant anchors manufacturer. We rec-

ommend performing regular tensile stress

tests, to verify that anchors have been set

correctly.

durlum metal ceilings are dimensioned

such that they carry their own weight of

the system construction plus a surface

load amounting to 40N/m². Higher loads

must be taken into account or suspended

separately in the construction, and the

measures must be adapted to the situa-

tion at hand. Usually, built-in components

and loads must be suspended separately.

For ceiling systems that do not allow any

tolerance compensation within a module,

GENERAL INFORMATION

suitable material expansions must be tak-

en into account.

Building expansion joints and tolerances

customary in building construction must

be taken into account accordingly.

durlum metal ceilings must always be as-

sembled by expert dry building companies

who are capable of assessing the overall

situation in the building, the metal ceil-

ing, the cladding surface, as well as the

structural conditions and are able to take

suitable precautions for ensuring proper

assembly.

If parts from different manufacturers are

used to assemble the ceiling, the relevant

mounting company must provide the cer-

tificates required by EN 13964:2007 and

must obtain suitable certificates of con-

formity itself.

Liability for proper selection of the products

and system conformity can only be as-

sumed for the systems delivered by durlum.

To prevent the parts from becoming dirty,

gloves must be worn during assembly. If

the ceiling products are delivered laminat-

ed with a protective film, they must be pro-

tected from exposure to UV radiation [sun-

light], the film must likewise be removed

from the goods no later than 4 weeks af-

ter delivery, and the storage temperature

must not exceed 30°, since otherwise the

adhesive on the panel may become hard-

ened, and the protective film can no long-

er be removed.

STORAGE

durlum metal ceilings are usually delivered

on pallets. It is advisable to leave the metal

panels on the pallets as long as possible. If

the pallets need to be opened, the durlum

POLYLAM®should always be placed on its

underside.

Storage must be carried out such that

damage is excluded.

The assembly of the ceiling panels must

not start until all dust-producing work has

been completed [swept clean].

durlum products are certified according

to ISO 9001 for development, production,

sales and also for service. Nevertheless, it is

recommended to always subject the metal

ceilings immediately to an inspection and

to report any complaints right away [usu-

ally immediately following delivery or within

3 days]. Visible damage must be noted on

the delivery note.

CERTIFICATE

The Certification Body

of TÜV SÜD Management Service GmbH

certifies that

durlum GmbH

An der Wiese 5

79650 Schopfheim

Germany

has established and applies a

Quality and Environmental Management System

for the following scope of application:

Planning, development, manufacturing and sales of

metal ceilings, functional ceilings, luminaires,

lighting and daylight systems.

Performance of audits (Report-No. 70014435)

has furnished proof that the requirements under:

ISO 9001:2008

ISO 14001:2004

ISO 50001:2011

are fulfilled. The certificate is valid from 2014-07-27 until 2017-05-29.

Certificate Registration No. 12 100/104/340 25601 TMS

Product Compliance Management

Munich, 2014-06-17