6

pH

The pH of water measures its acidity or its alkalinity. Water with a pH of less than 7.0 is acidic, above 7.0 is alkaline, and 7.0

is neutral. The lower the pH value is below 7.0, the greater the acidity and the higher the pH value is above 7.0, the more

alkaline. Acidic water (pH less than 7.0) is corrosive to pipes, appliances, etc. A pH of 7.0 or higher facilitates iron removal

— which is why the filter is designed to increase the pH when it is less than 7.0.

The pH increasing component of the media is “sacrificial”. That is, it slowly dissolves during the process of increasing pH.

The rate at which this occurs is proportional to the pH increase and the water consumption rate (i.e. the greater the pH

increase and the water consumption, the greater the sacrificial rate). Thus, when the pH is increased to 8.2 or more as

is necessary when manganese is present, the sacrificial rate is even greater. Under the most severe conditions, the MpH

component of the media may have to be replenished two to four times per year. On the other hand, if the raw water pH is

7.0 or above and no manganese is present, the sacrificial rate is very slight.

Tannins (Humic Acid)

Tannins (also known as humic acid), which are present in some supplies, are the result of decaying vegetable matter.

If the tannin concentration is above approximately 0.5 ppm, it will form a sticky coating on the media, thus rendering it

incapable of filtering the iron. A chemical free iron filter is not recommended for this situation. If the tannin concentration is

less than 0.5 ppm, a chemical free iron filter may be installed.

Hydrogen sulfide (h2s)

Hydrogen sulfide (often referred to as “sulfur”), is easily detectable by its objectionable “rotten egg” odor. Sulfur corrodes

iron, brass, copper and silver. A chemical free iron filter is not recommended when hydrogen sulfide is the only water

problem, although it is capable of removing sulfur in concentrations of up to 2 to 3 ppm. Whenever hydrogen sulfide is

present, backwashing must be performed at more frequent intervals and the pumping system MUST include a standard air-

to-water pressure tank with an air relief valve.

Check Your Water Pressure and Pumping Rate

Two water system conditions must be checked carefully to avoid unsatisfactory operation or equipment damage:

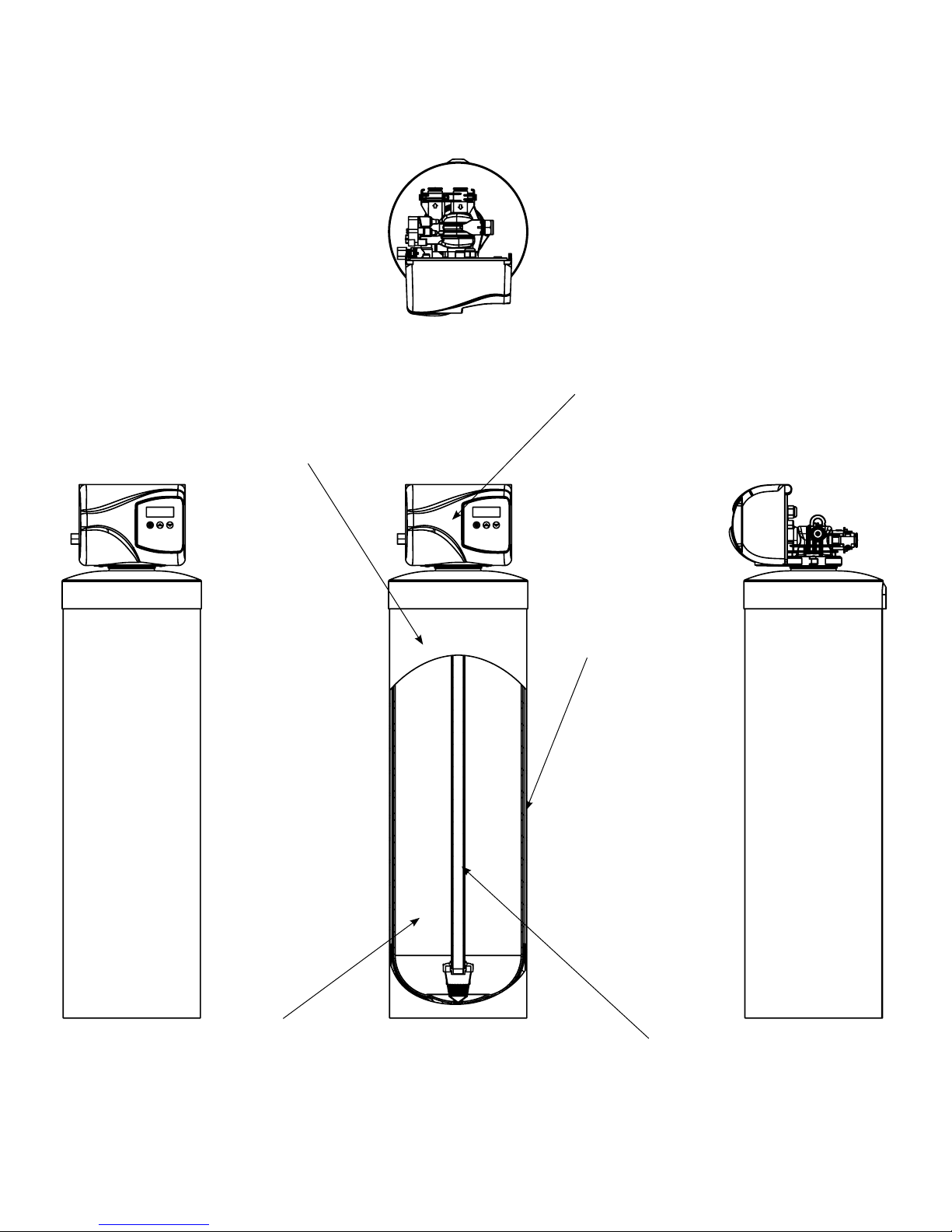

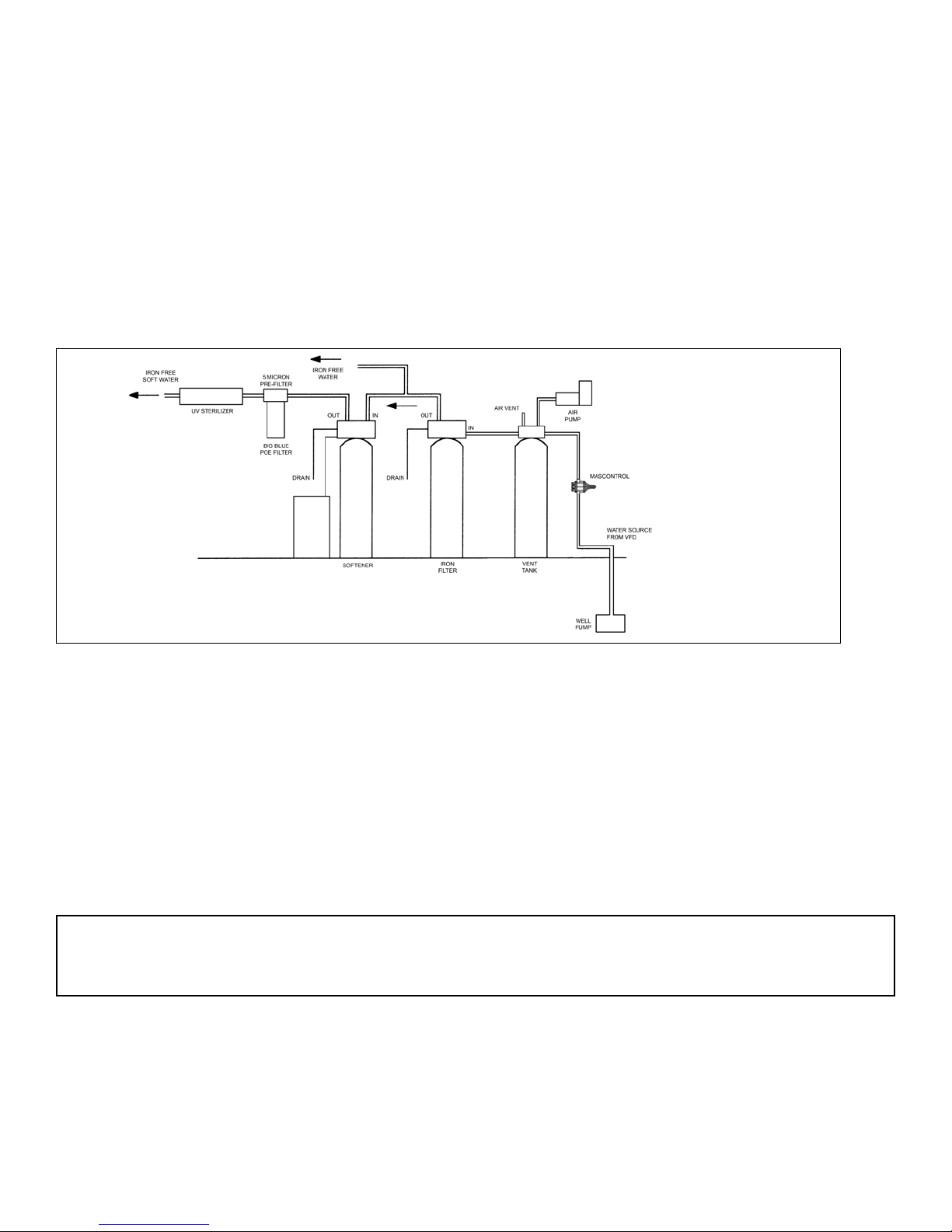

1. Minimum water pressure required at the filter tank inlet is 20 psi. If pressure is over 50 psi, a pressure reducing valve must

be installed in the water supply line ahead of the hydrocharger (Fig. 1, 2 or 3, Page 8).

2. The pumping rate of your well pump must be at least 5 gallons per minute (gpm) for satisfactory operation of

the hydrocharger. In addition, the pumping rate must equal the required backwash flow rate of your model (see

Specifications on Page 1 for backwash flow rates). To measure the pumping rate of your pump, follow these

instructions:

a. Make certain no water is being drawn. Open spigot nearest pressure tank. When pump starts, close spigot and

measure time (in seconds) to refill pressure tank (when pump shuts off). This figure represents cycle time.

b. With the pressure tank full, draw water into a container of known volume and measure the number of gallons drawn

until the pump starts again. This is draw-down. Divide this figure by cycle time and multiply the result by 60 to arrive at

the pumping rate in gallons per minute (gpm). To aid in your calculation, insert the data in the following formula:

DRAWDOWN________÷ CYCLE TIME______________x 60

(gals) (seconds)

= PUMPING RATE______________

(gpm)

EXAMPLE: DRAWDOWN is 6 gals; CYCLE TIME is 53 secs; then, PUMPING RATE equals:

6 gals ÷ 53 secs x 60 = 6.8 gpm

See Specifications on page 2 for minimum flow rates.

NOTE: If your pumping rate is inadequate, do not install your filter until the problem is solved.