Contents

Important information

1About this document .. . . . . . . . . . . . . 3

1.1 Warnings and symbols .. . . . . . . 3

1.2 Copyright information .. . . . . . . . 4

2 Safety .. . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1 Intended purpose .. . . . . . . . . . . 4

2.2 Indications .. . . . . . . . . . . . . . . . . 4

2.3 Contraindications .. . . . . . . . . . . . 4

2.4 Intended use .. . . . . . . . . . . . . . . 4

2.5 Improper use .. . . . . . . . . . . . . . . 4

2.6 General safety information .. . . . . 5

2.7 Systems, connection with other

devices .. . . . . . . . . . . . . . . . . . . 5

2.8 Standards .. . . . . . . . . . . . . . . . . 5

2.9 Specialist personnel .. . . . . . . . . 5

2.10 Electrical safety .. . . . . . . . . . . . . 6

2.11 Essential performance charac-

teristics .. . . . . . . . . . . . . . . . . . . 6

2.12 Notification requirement of seri-

ous incidents .. . . . . . . . . . . . . . . 6

2.13 Only use original parts .. . . . . . . . 6

2.14 Transport and packaging .. . . . . . 6

2.15 Disposal .. . . . . . . . . . . . . . . . . . 6

2.16 Protection from threats from the

Internet .. . . . . . . . . . . . . . . . . . . 6

Product description

3Overview .. . . . . . . . . . . . . . . . . . . . . . . 8

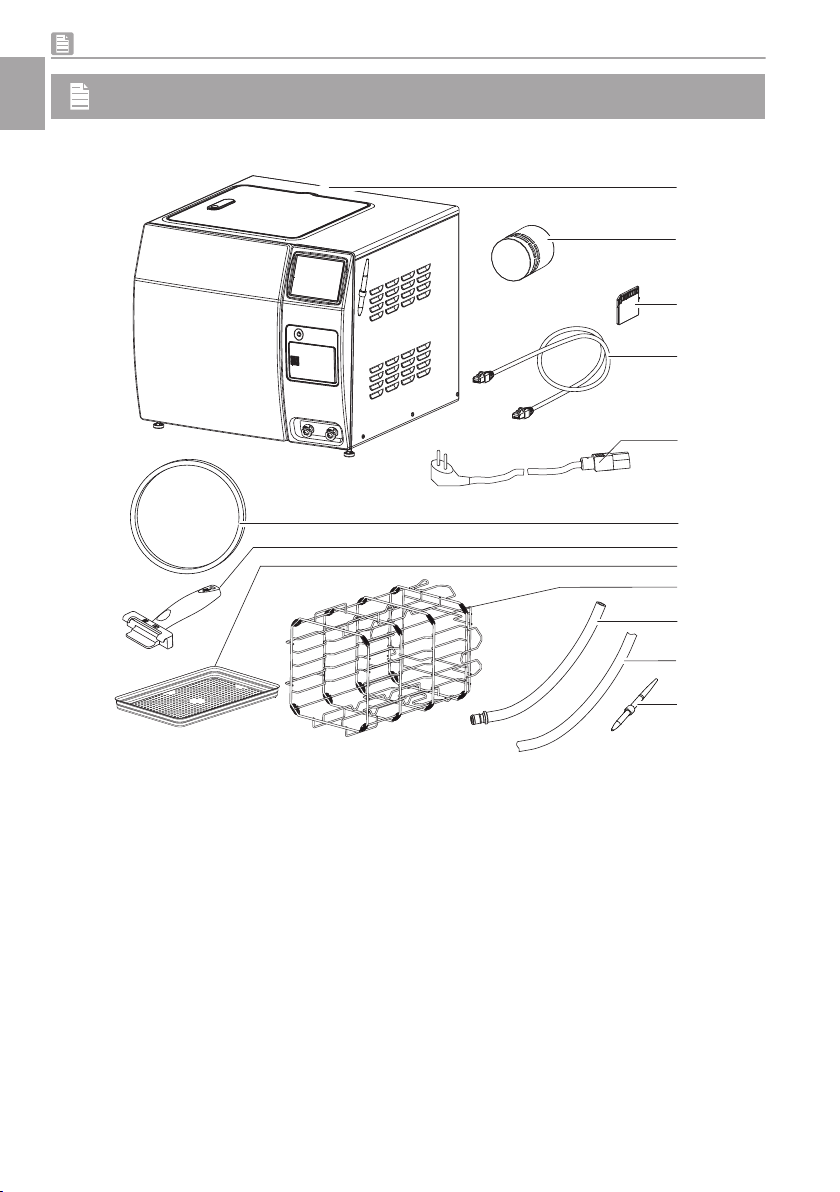

3.1 Scope of delivery .. . . . . . . . . . . . 9

3.2 Accessories .. . . . . . . . . . . . . . . . 9

3.3 Optional items .. . . . . . . . . . . . . . 9

3.4 Consumables .. . . . . . . . . . . . . . 9

3.5 Wear parts and replacement

parts .. . . . . . . . . . . . . . . . . . . . . 9

4Technical data .. . . . . . . . . . . . . . . . . . . 10

4.1 Type plate .. . . . . . . . . . . . . . . . . 12

4.2 Evaluation of conformity .. . . . . . 12

5 Operation .. . . . . . . . . . . . . . . . . . . . . . 13

5.1 Hygoclave 90 .. . . . . . . . . . . . . . 13

5.2 Safety devices .. . . . . . . . . . . . . . 15

5.3 Overview of programs .. . . . . . . . 17

Assembly

6 Requirements .. . . . . . . . . . . . . . . . . . . 18

6.1 Installation/setup room .. . . . . . . 18

7 Installation .. . . . . . . . . . . . . . . . . . . . . . 18

7.1 Carrying the unit .. . . . . . . . . . . . 18

7.2 Remove the transport locks .. . . 18

7.3 Setting up the unit .. . . . . . . . . . . 18

7.4 Removing the protective film

from the touch screen .. . . . . . . . 19

7.5 Checking the SD memory card .. 19

7.6 Checking the air filter .. . . . . . . . . 20

7.7 Connecting the unit .. . . . . . . . . . 20

7.8 Connecting the device to the

network .. . . . . . . . . . . . . . . . . . . 22

7.9 Connecting a label printer .. . . . . 22

8Configuring the unit .. . . . . . . . . . . . . . 24

8.1 Selecting the access level .. . . . . 24

8.2 Entering dealer information .. . . . 24

8.3 Language selection .. . . . . . . . . . 24

8.4 Configuring the device with a

network connection .. . . . . . . . . . 24

8.5 Set the date and time. .. . . . . . . . 24

8.6 Parameter selection .. . . . . . . . . . 25

8.7 Configuring a log printer .. . . . . . 25

8.8 Configuring the label printer .. . . . 25

8.9 Configuring the network drive .. . 25

8.10 Monitoring the unit via the net-

work .. . . . . . . . . . . . . . . . . . . . . 26

8.11 User management .. . . . . . . . . . . 27

8.12 Setting up the calendar .. . . . . . . 27

8.13 Touch screen .. . . . . . . . . . . . . . . 27

8.14 Resetting counter readings .. . . . 28

9Test programs .. . . . . . . . . . . . . . . . . . . 28

9.1 Vacuum test .. . . . . . . . . . . . . . . 28

9.2 Bowie-Dick test .. . . . . . . . . . . . . 29

10 Validation for commissioning .. . . . . . . 29

Contents

6046100064L02 2007V003 1

EN