WARNING!

Keep hands and clothing clear of all moving parts.

EMERGEN Y STOP

In case of emergency, release rounding lever, flip

power switch to OFF, and raise handle.

ADJUSTMENTS

All adjustments have been made at the factory, however,

readjusting may be required upon installation, and

periodically during use.

2. Motor Belt tension will require tightening as belts

wear and stretch.

WARNING!

Before removing cover, place power switch in

the OFF position and disconnect the machine

from the power source.

To adjust, see Fig. 5. Remove cover from side of base.

With a wrench, loosen locking nut, turn knob clockwise

by hand to tighten belts. The belts should have

approximately 1/16 inch deflection. Retighten the lock

nut and replace the cover. This adjustment must be

tested after being made.

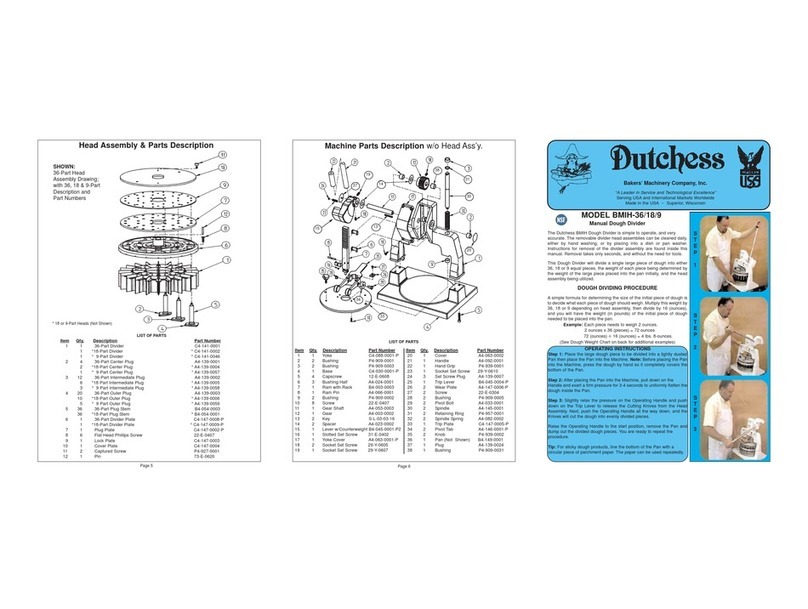

Figure 5

3. Drive Slide adjustment is to stop the crank plate in the

center, when releasing the rounding lever, See Fig.6.

The crank plate must be removed to make this adjust

ment. (To remove crankplate, see instructions on page

10, Item 7) Loosen lock nut and turn set screw counter

clockwise, to allow drive slide to come back to center.

Tighten lock nut. If drive slide is coming back beyond

center, loosen lock nut, turn set screw clockwise,

pushing drive slide to center. Tighten lock nut.

HEAD REMOVAL

To remove the head assembly for cleaning, or for

interchanging with one of the optional head assemblies

of other divisions.

AUTION!

A pallet must be in place on the crank plate when

removing and installing the head assembly.

Note: When properly set, the Stop Rod

Bumper should compress ver slightl

during the ROUNDING PRO ESS.

5

Figure 4

1. Your new Dutchess Divider/Rounder comes

equipped with a "Expandable Pocket" design.

Experimentation will be required to determine the

correct pocket height for each size dough ball. To

increase the pocket height, loosen the locking nut by

turning counter clockwise. Turn the stop rod

clockwise to decrease pocket height (for smaller rolls)

and counter clockwise to increase pocket height (for

larger rolls). Retighten locking nut before rounding by

turning clockwise. See Fig. 4

Figure 6