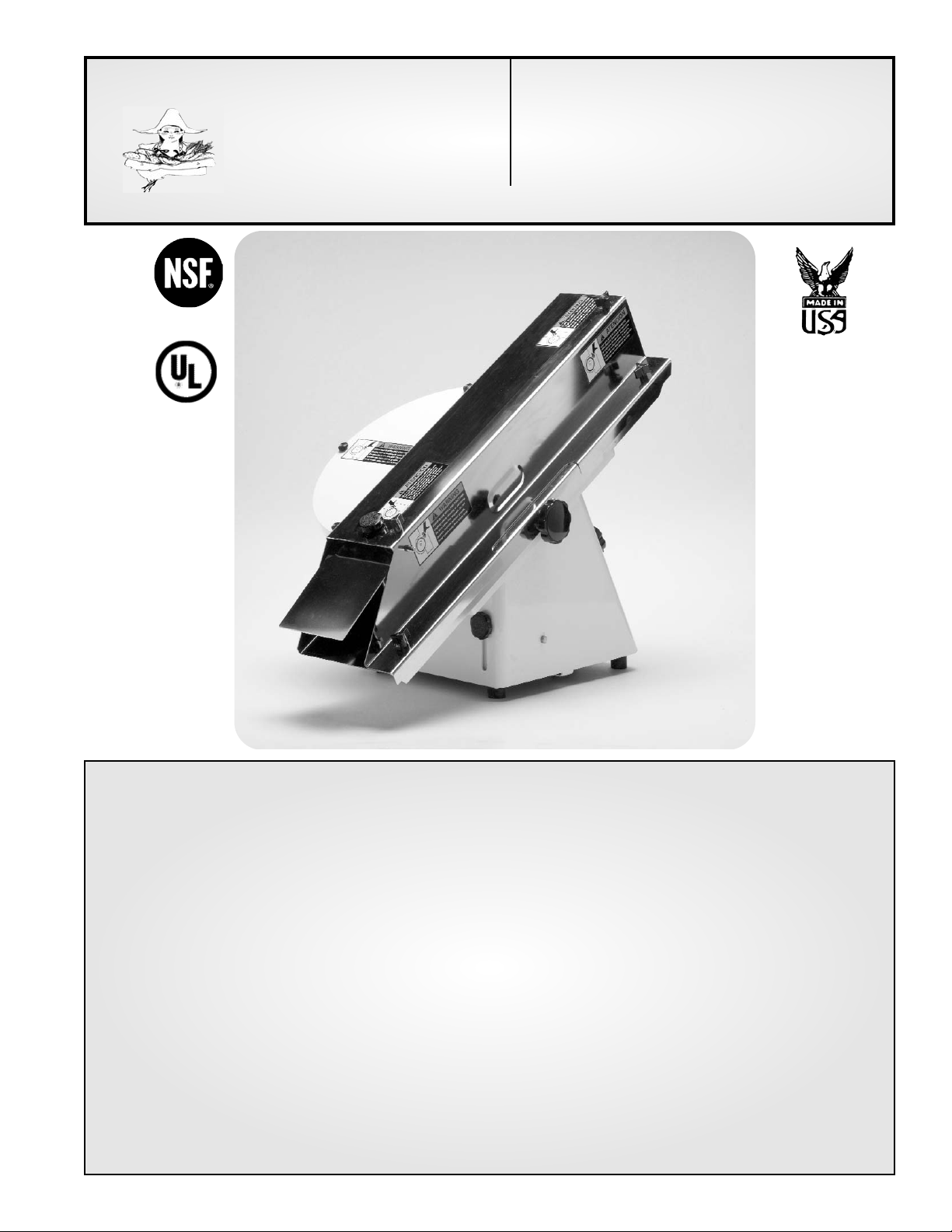

DUTCHESS MODEL 270C

BUN & BAGEL SLICER

Operator Instructions and Safety Information

All employees operating, servicing and cleaning this machine must be properly trained as to its

operation and safety features.

WARNING: The slicing Blade is sharp and dangerous. Keep hands out of the cutting

area. A severe cutting or abrasion injury could result. Do not operate

this machine without guards in place.

WARNING: The slicing Blade is sharp and dangerous. Never attempt to clear a

product jam with your hands. A severe cutting or abrasion injury could

result. To clear a product jam, turn the machine “OFF”, disconnect the

power supply, push forward on the Blade Brake to stop the Blade from

rotating and then clear the Chute using a flat instrument.

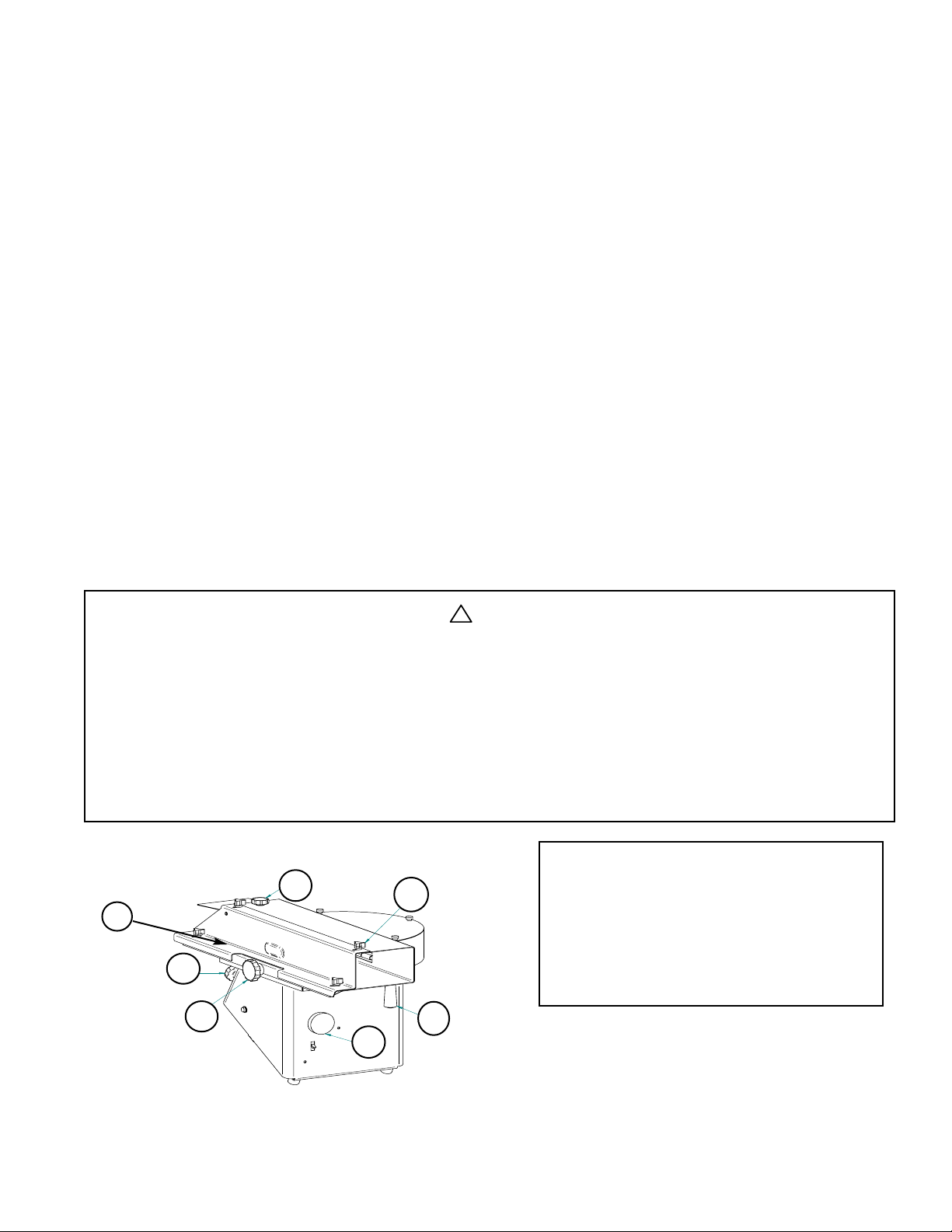

NOTE: Product can be removed easier by increasing the Blade cutting

height by turning the Large Black Knob [3] clockwise. (see Figure 1,

page 6)

WARNING: The Blade on the Model 270C Slicer will coast to a stop after the power

is switched to “OFF”. To prevent personal injury or possible damage to

the Slicer components, wait for the blade to stop completely before

making any adjustments. Blade can be stopped much quicker by

pushing forward on the Blade Brake.

IMPORTANT: It is imperative that the Slicer Blade is kept sharp and that the machine

is cleaned frequently. Slicing dense products or those with additives

such as raisins, nuts, or dried fruit chips may cause premature unit

wear or even failure if:

1) The Blade is not kept sharp.

2) The Slicer is not cleaned frequently.

3) The rate at which the product is fed into the Slicer is too great.

IMPORTANT: Safety and instructional labels are easily visible to the operator and

are located near any area of potential danger. Replace any decal that

becomes damaged or worn.

WARNING: TURN THE MACHINE OFF AND DISCONNECT THE POWER SUPPLY

BEFORE PERFORMING ANY TYPE OF SERVICING, CLEANING,

MAINTENANCE OR INSPECTIONS.

The General Safety Practices listed on the following pages are recommended precautions

and not related to any specific procedures. Operators should understand and apply these

safety precautions during all phases of operation and maintenance.

1

Read and understand all instructions and safety practices before attempting operation!

Pay particular attention to Warning and Caution messages indicating personal safety

instructions. Failure to comply with safety instructions may result in serious personal

injury.