Connecting Sensor to Fitting

For hot-tap installation, use a 1-3/8˝ (35 mm) hole saw bit to create the opening for

installation of the 1-1/2˝ full port ball valve.

It is recommended to use a weld-on or saddle female tting with 1-1/2˝ or 2˝ NPT

connection, depending on the sensor model. Use proper pipe sealant on sensor

threads. When threading the sensor into the tting use the wrench ats on the bottom

of the housing to prevent damage to the sensor.

The sensor must be aligned with the direction of ow. In order to align the sensor

properly, insert the 7/64 allen key into the alignment hole. Then, thread the sensor into

the tting, ensuring that the allen key is pointing downstream in the direction of ow.

Note: Do not turn the allen key and loosen the screw in the alignment hole.

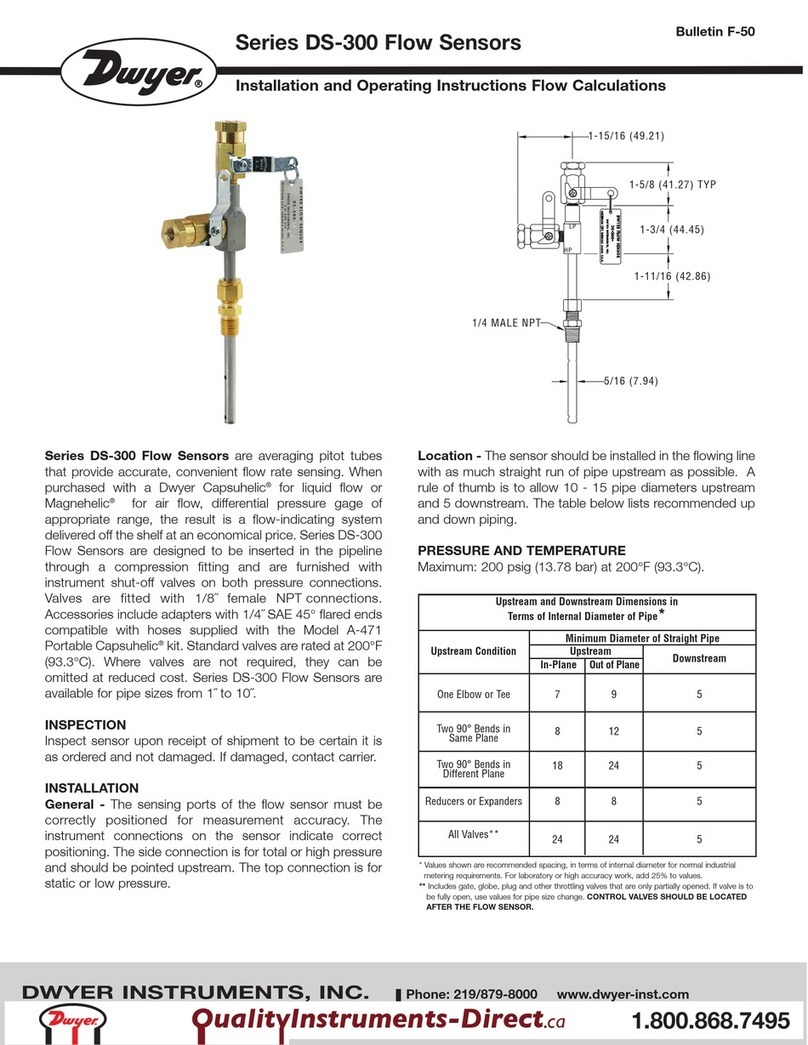

Sensor Height

The sensor must be installed so that the impeller shaft is located 10% inside the

pipe ID. To install properly the sensor install height, “H” shown in Figure 2, must be

calculated and used. Table 2 on page 3 in this instruction manual has “H” dimensions

for standard pipe materials and sizes.

If your application pipe is not listed in Table 2 it will need to be calculated with the

following procedure:

1. Using a ruler measure the pipe ID and the pipe wall thickness.

Pipe Wall Thickness:_______ Pipe ID:_______

2. Use the following equation to gure “H”:

For Standard PFT:

H = 5.85 – Pipe Wall Thickness – (0.10 x Pipe ID)

H = _____

For PFT hot tap:

H = 11.85 – Pipe Wall Thickness – (0.10 x Pipe ID)

H = _____

Once “H” is known, adjust the sensor so that “H” is the distance from the bottom of the

sensor ange to the top of the pipe. The insertion height of the sensor is adjustable by

loosening the top and bottom nuts on the sensor ange and then moving the sensor

ange up or down as needed.

Final Sensor Alignment

The sensor must be aligned with the direction of ow. Insert the supplied 7/64 allen key

into the set hole in the side of the hex hole plug. Based on the initial installation, the set

hole should already be roughly aligned with the process ow.

If necessary, make nal alignment adjustments by loosening the three 3/32˝ set screws

around the sensor ange with the supplied allen key.

Once the set screws are loosened, replace the allen key in the alignment hole and

rotate the sensor in line with the downstream ow. The sensor can be rotated ±60°.

Note: Do not turn the allen key to loosen the screw in the alignment hole.

Once nal alignment is made, tighten the screws in the sensor ange and tighten the

height adjustment nuts.

Figure 2: Sensor install height

DIRECTION OF FLOW

PIPE

OM OF

ALIGNMENT ROD

H[2] 3/32 HEX DRIVE

ALIGNMENT SET

[DO NOT REMOVE]

INSTALLATION

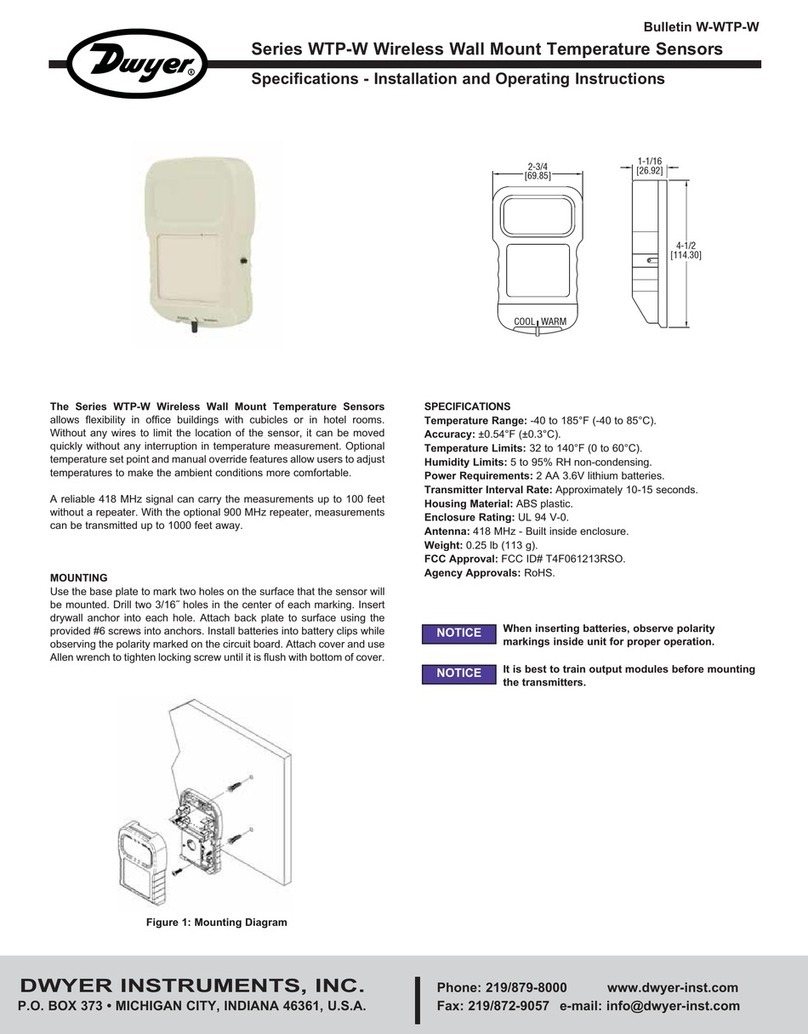

Fitting Position

Bubbles, turbulence, and sediments will cause improper operation. For best operation,

mount 30° to 150° off vertical on horizontal runs (see Figure 1). Allow a straight run

of at least 10 pipe diameters upstream and 5 pipe diameters downstream to insure

optimal ow measurement. See Table 1 for recommendations for other mounting

requirements.

Ensure that the process uid is compatible with the wetted

materials.

Ensure that the system is not pressurized before installing or

removing this device or other objects from the system. The device

and/or object may become a projectile.

CAUTION

Table 1: Fitting location

Upstream Item Upstream Diameters Needed

Flange

Reducer

Valve/Pump

90° Elbow

10

15

50

20

Figure 1: Mounting orientation

30 ∞ 30 ∞

30 ∞ 30 ∞

OKOK

BUBBLES

[AVOID]

SEDIMENT

[AVOID]

Do not remove or unscrew the hex hole plugs.

Do not exceed the maximum device ratings.

NOTICE

WARNING

Be careful not to damage the signal wire during installation.

CAUTION

NOTICE