- 5 -

Additional Parts Required But Not Supplied

Hardware

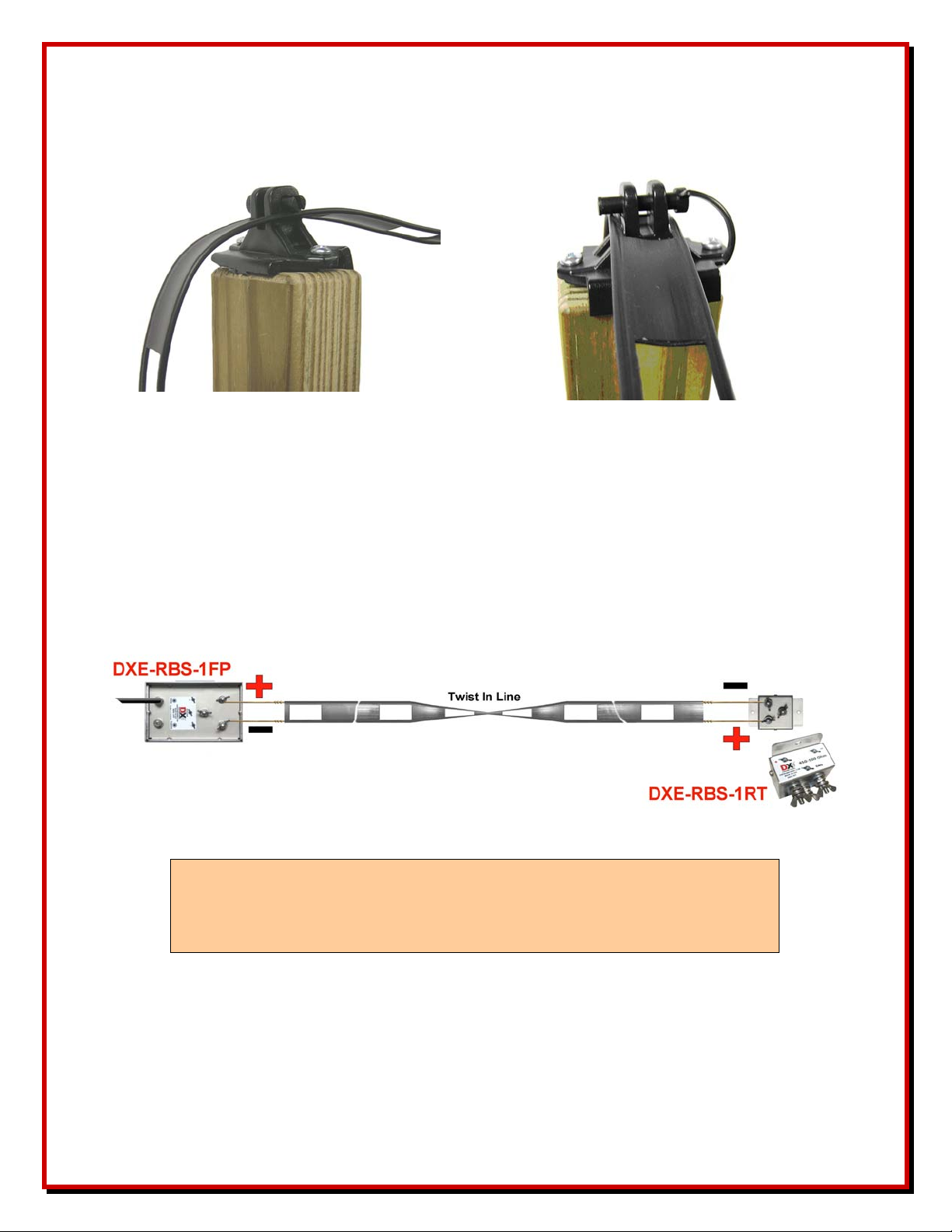

Supports and insulators for mounting the DXE-RBS-1FP Feed Point unit, the DXE-RBS-1RT

reflection transformer and the antenna wire.

For the antenna run, non-conductive supports are best, however metal tubing can be used if the

antenna line is kept a couple of inches away from the metal supports using non-conductive spacers.

This prevents any degradation of system performance due to mutual coupling. DX Engineering

offers a very convenient insulator (See Figure 4) for securing the 450 ladder line to wood

supports. They also lock the line in place. Part number DXE-LL-INS includes 25 insulators.

The use of a non-conductive mounting configuration for the DXE-RBS-1FP and DXE-RBS-1RT

is also highly recommended. Use pressure treated posts or perhaps a handy tree. If mounting these

units on conductive supports (i.e., a metal fence post or pipe) keep the feedline a couple of inches

away from the support using non-conductive spacers as well. If a pipe is used to mount the DXE-

RBS-1FP Feed Point unit, use a V-Saddle clamp, part number DXE-CAVS-1P, that accepts pipe

sizes from 1/2” to 1-3/4”. The DXE-RBS-1RT reflection unit is flanged for mounting and requires

two wood or metal screws.

To enhance weather resistance of the DXE-RBS-1RT, it may be useful to put a bead of non

corrosive, marine grade silicone, like DX Engineering DXE-RTV598335,along the seams where

the two halves of the cases meet. Leave a small opening in the seams at their lowest point to allow

any condensation to drain. Silicone which contains acetic acid, which has a vinegar-like smell, is

corrosive to aluminum and should be avoided.

Ground Rods

A minimum of two, 5 foot, 3/4 inch OD or larger copper ground rods and clamps are required. One

rod is needed for each end of the antenna. In poor soil, adding an additional ground rod to each end

may improve performance. As an alternative, 3/4 inch OD copper water pipe works well.

Feedline

Use 75 coaxial cable with F-type coaxial cable connectors from the feed point unit to the

operating position. We recommend using a high quality 75 “flooded” RG-6 type coax such as DX

Engineering DXE-F6-SPL. Flooded style cables have the distinct advantage of automatically

sealing small accidental cuts or lacerations of the jacket. Flooding also prevents shield

contamination and the coaxial cable can be direct-buried. This coaxial cable is available with F-

Connectors installed and in any desired custom length from DX Engineering.

Preparing flooded F-6 cable for connectors not difficult with the correct tools. DX Engineering

offers an inexpensive stripping tool, part number DXE-CPT-659, that strips the F-6 coaxial cable in

one operation and the tool includes an extra cutting cartridge.

It is essential that the feedline connections are of high quality and weather resistant. The feedline is

used not only for the received signal, but also carries the voltage used for directional control. For