4

velocity factor of 84% (0.84). During phased array operation, due to mutual coupling, each vertical

antenna has a different operating impedance. This means transmitter power is not evenly divided by

the Four Square System Phasing Unit. The highest effective power into any element feed cable is

approximately half of the applied power, which means the overall system can handle approximately

twice the 1:1 SWR 75Ω cable ratings when used in this application. Properly prepared 1/4-wave

cables may be ordered from DX Engineering Customer Service.

If you already have a four square array with a Comtek or similar hybrid controller and would like to

improve overall performance, add the power handling capability and Omni feature of the DX

Engineering TFS4 Transmit Four Square Series, which is essentially a direct replacement system. A

slight shift downwards in optimum performance frequency may result from this substitution.

Control is accomplished using a four-wire control cable to perform all the necessary switching

functions when connected to the included DXE-CC-4SQR Transmit Four Square Control Console.

Optional DXE-CW9 CAT 5 control cable is available from DX Engineering. Push-button switching

allows instantaneous direction change. Your amplifier keying or relay line should be routed through

the control console. This prevents catastrophic failures caused by relay transfer while the amplifier

is activated. The DXE-CC-4SQR Control Console allows you to call for pattern changes while

transmitting without damaging relay contacts.

Features

Four Directions PLUS Omni - versatile operation

5 kW CW Power Rating - high reliability

10 kW PEP SSB

Hot switching lockout - disables amplifier during directional changes

Drop-in replacement for Comtek - easy upgrade

Proven DX Engineering RF Relays - high performance

RF Shielded Weatherproof Housing - unique protection

Custom label with four compass direction sets for the Control Console

Relays cycle during Power-On

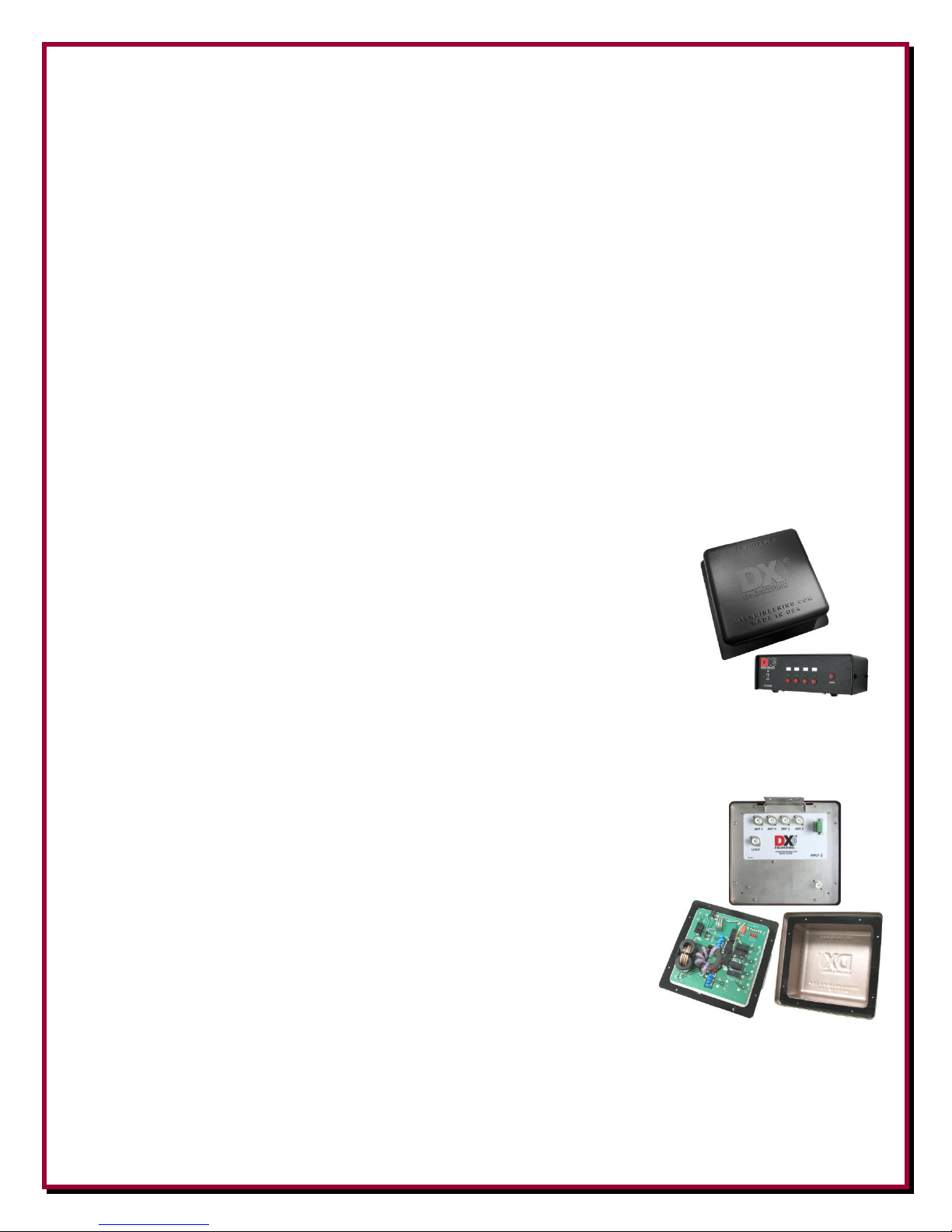

The DX Engineering Transmit Four Square system consists of a Transmit Four Square Control

Console that has four momentary contact light-touch push-button

switches for direction control and one push-button for omni selection.

There is a toggle switch for power on/off, and four variable brightness

green LEDs (light emitting diodes) to show the system's current

direction. A custom label for the Control Console to indicate four

antenna directions. During Omni operation, all four LEDs light at the

same time. A 2.1 mm DC power cord is supplied with the unit.

The custom made Four Square System Phasing Unit must be located at

the center of the four square antenna system. Also included is a DXE-

SSVC-2P V-Clamp for mounting the Four Square System Phasing Unit.

Note: UMI-81343 Never-Seez®or DXE-NSBT8 Anti-Seize should be

used on all clamps, bolts and stainless steel threaded hardware to prevent galling and to ensure

proper tightening.