3. Quick operation and pay attention to

How To Operate The Machine

1. To turn the power on, turn the key switch (7). The

power/battery indicator (I) will light up.

2. Check the battery capacity to see if it is full –all indicators

are lit up when full.

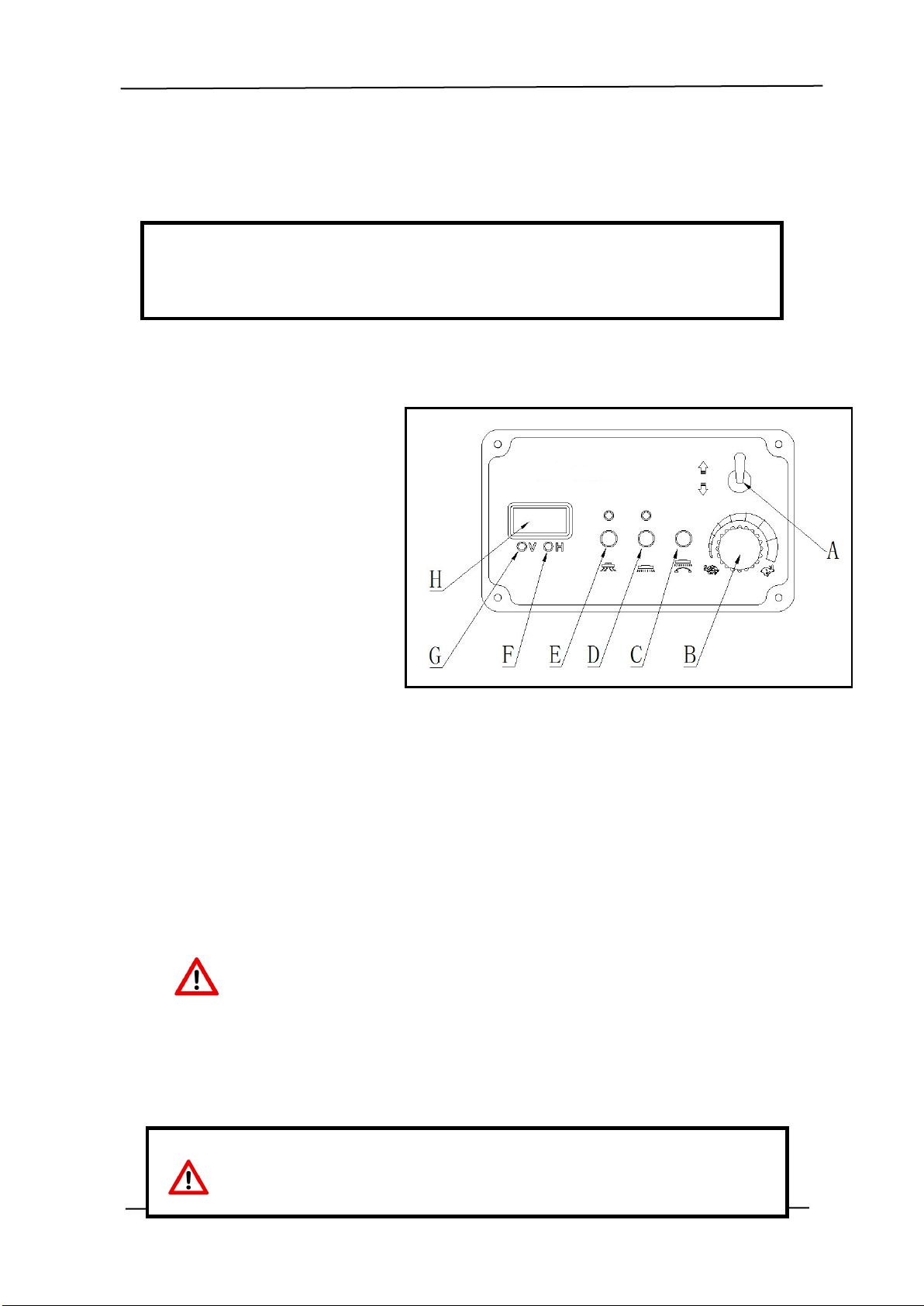

3. To turn on the brush motor, vacuum motor and the solution

flow, press the switches (D,E).

4. Lay down the squeegee release level (9), press the suction

motor button(E), the squeegee will start to work; when you

finish your work, press the button(E), the suction motor will

be stopped, then lift the squeegee up.

5. Move the knob A into" " position, the machine will move

forward automatically; while in " " position, the machine

will reverse automatically.

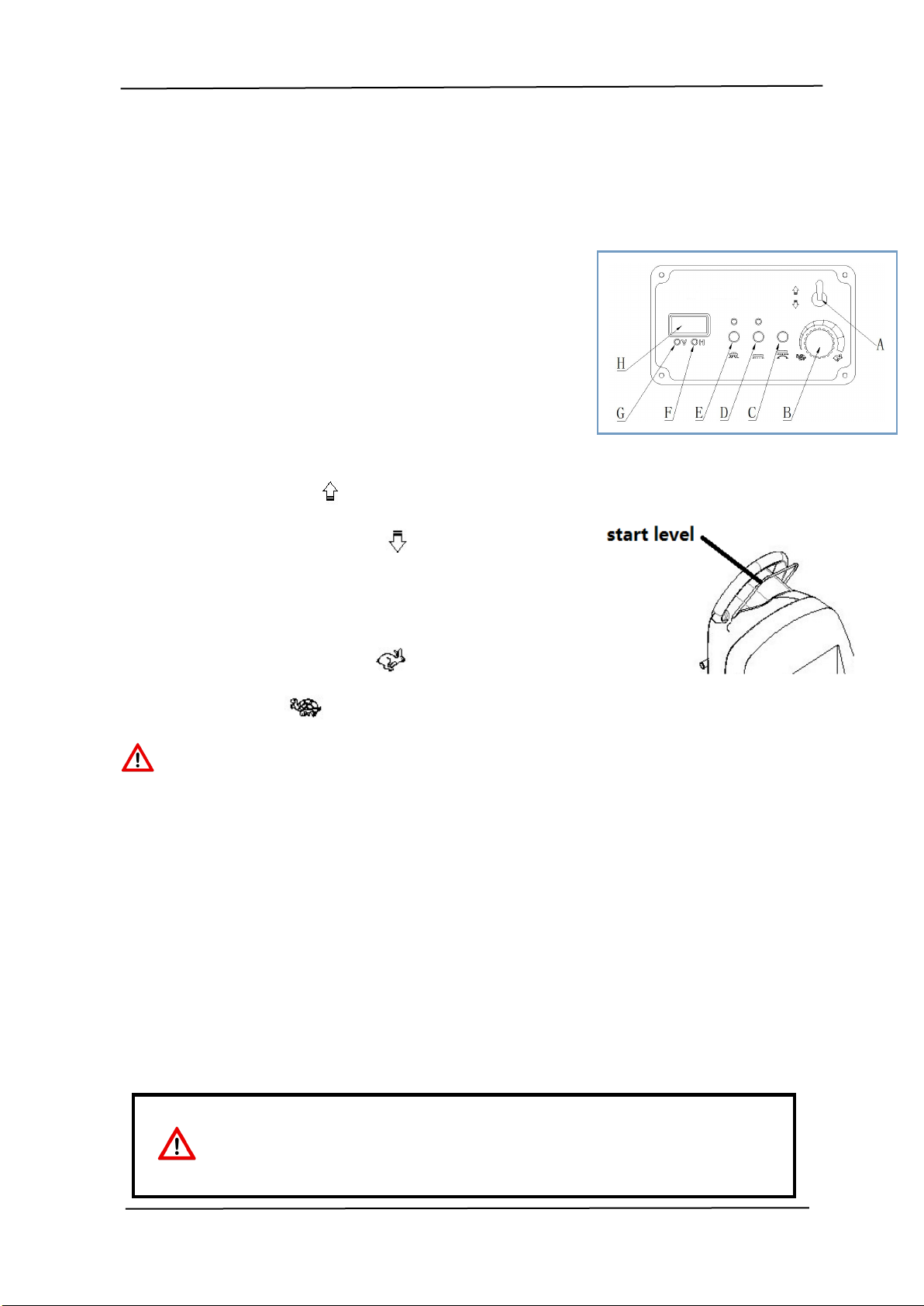

6. Hold the plastic handle, lift the metal start level, the machine

starts to move, release the start level, the machine stops.

7. Turn the speed adjust knob to" " side, you speed up the

machine, while to " " side, the speed will slow down

Turn off the brush motor before the brush is lifting.

Pay attention to before operate:

1)For the first time using machine, operator should be trained.

2)in the process of the replacement of the new, the original operator or supervisor to deal

with the new operator to carry out training to teach the operation and attention to matters,

to avoid unnecessary accidents.

3)understand, familiar with the place, determine the route of machine, to complete in

easiest and safest.

4)Check the battery capacity (the new machine or a longer period of time without the use

of the machine will be full of electricity before use).

5)choose brush or cleaning pad according floor situation