Dual Arm Articulating TV/Monitor Desk Clamp Mount (Butterfly Series)

Model: DE500D-C

Instruction Manual

Images may different from actual product

Disclaimer

It is Dyconn’s intention to have all the correct information represented within this manual.

Although we try our best, Dyconn makes no claim that the information comprised herein

covers all conditions or details in connection with installation or use of this product. Dyconn

assumes no responsibility for accuracy or adequacy of information comprised in this

document. The information comprised here is subject to change without notice or obligation

of any kind.

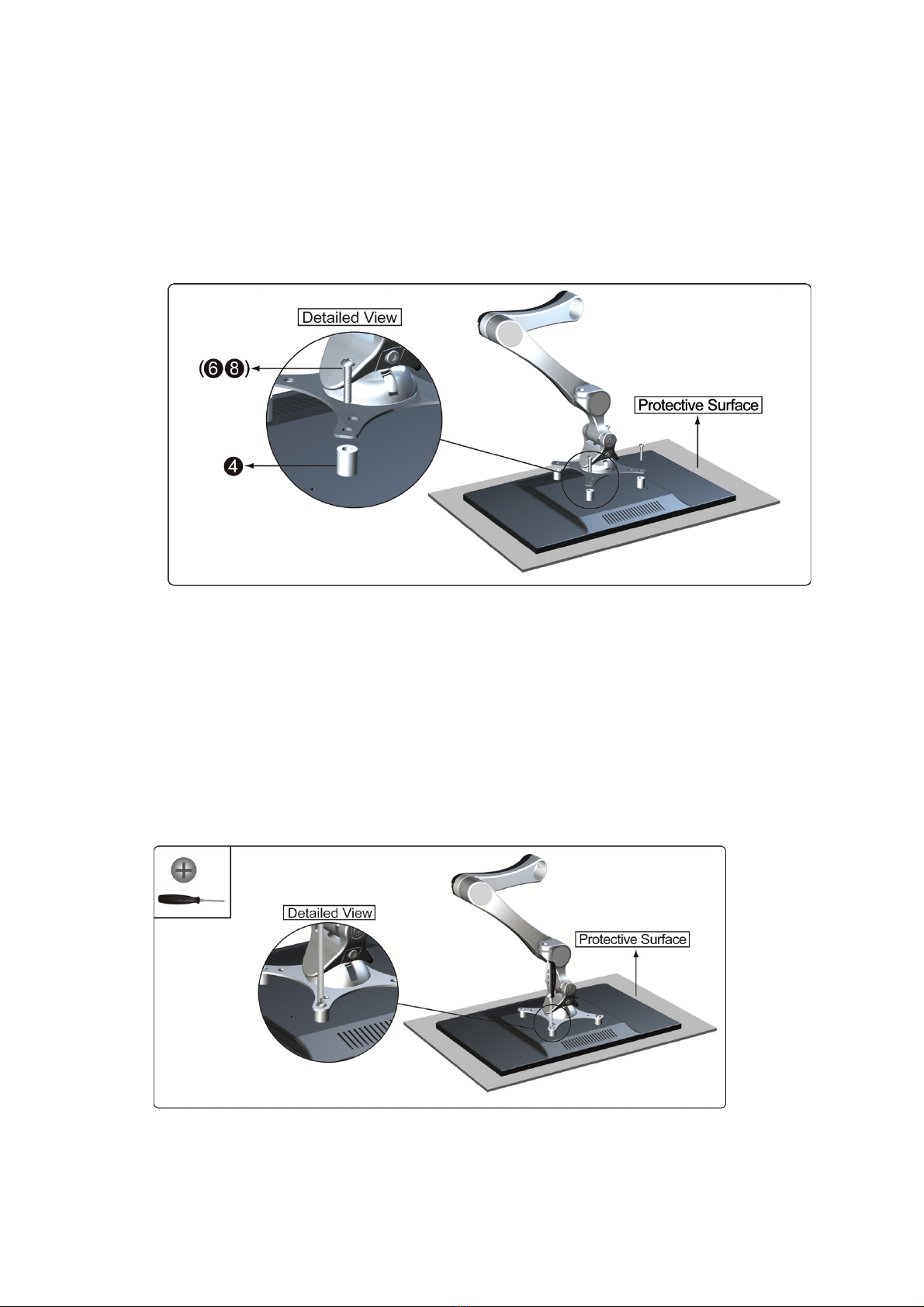

•A warning alerts you to the possibilities of personal injury or damage to equipment

if you do not follow the corresponding instructions. It is installer's responsibility to

make sure all components are properly assembled and installed using the

instructions manual provided.

•Using improper screws or screw size may damage your display. If spacers are

required, be sure to use correct size of screws. Proper screws will easily and

completely thread into the display mounting holes. Inadequate thread

engagement in the display may cause display to fall.

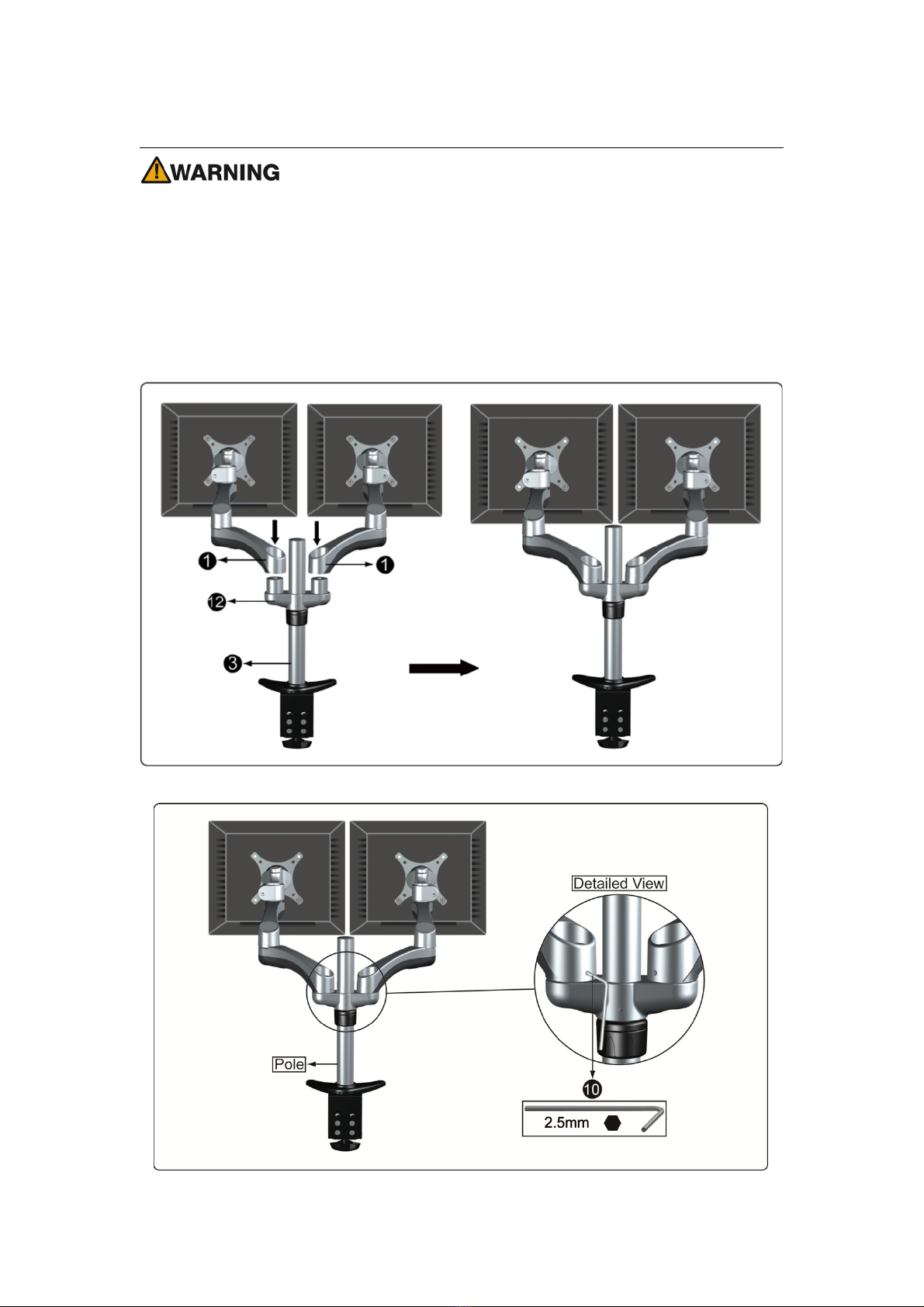

•It is installer’s responsibility to make sure the combined weight of all components

does not exceed weight capacity. Exceeding weight capacities can result in

severe personal injury or damage to equipment. It is installer’s responsibility to

make sure the maximum combined weight of all components does not exceed

weight capacity of 18Kg (39.6lbs)

•Allowing any part of your component cables to be caught between movable parts

can result in serious personal injury or damage to equipment.

Read the following warning before installing

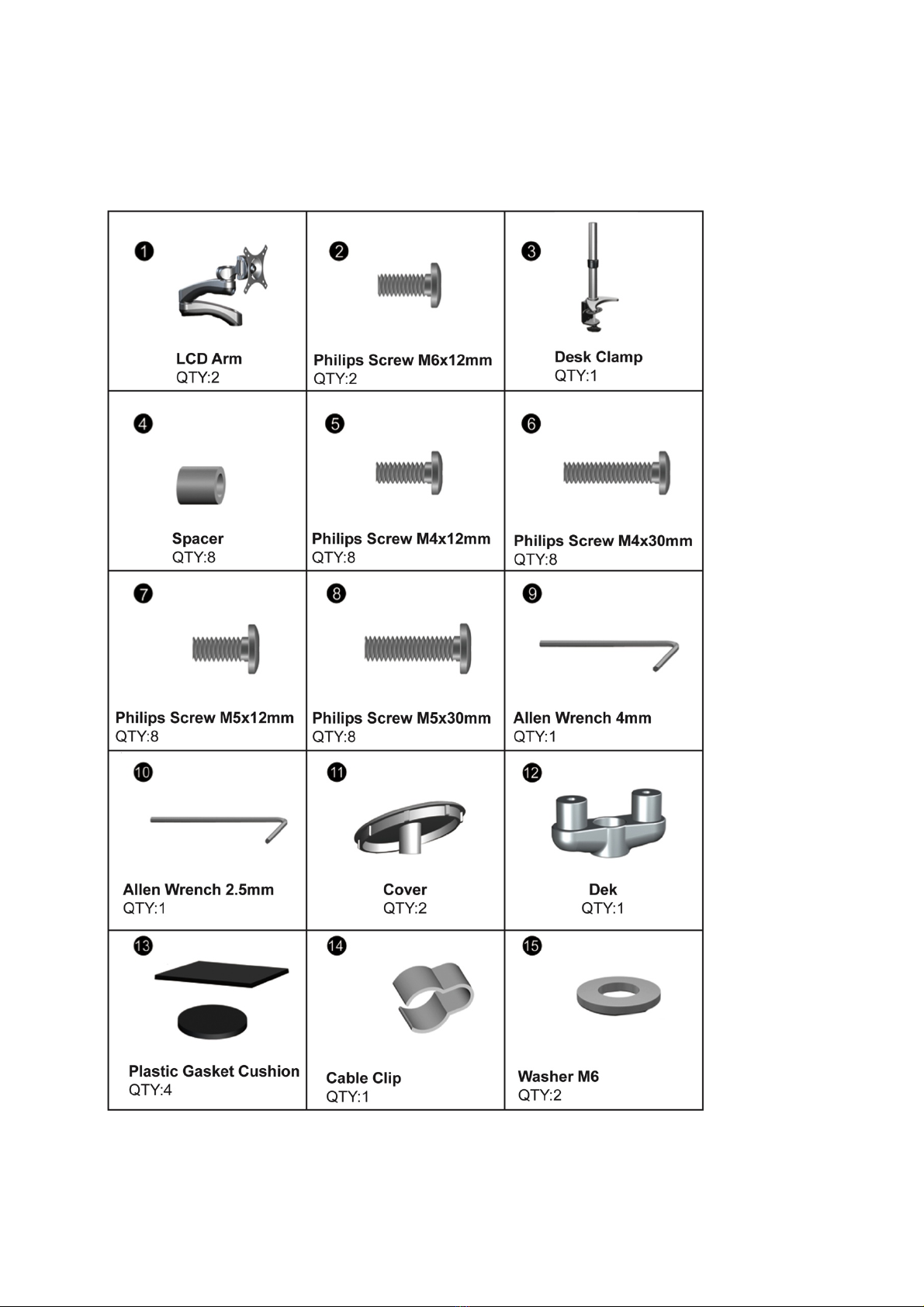

!Verify all parts are included. Do not install if the products or hardware is damage. Not

all hardware included will be used.

!This product contain moving parts, Use with caution

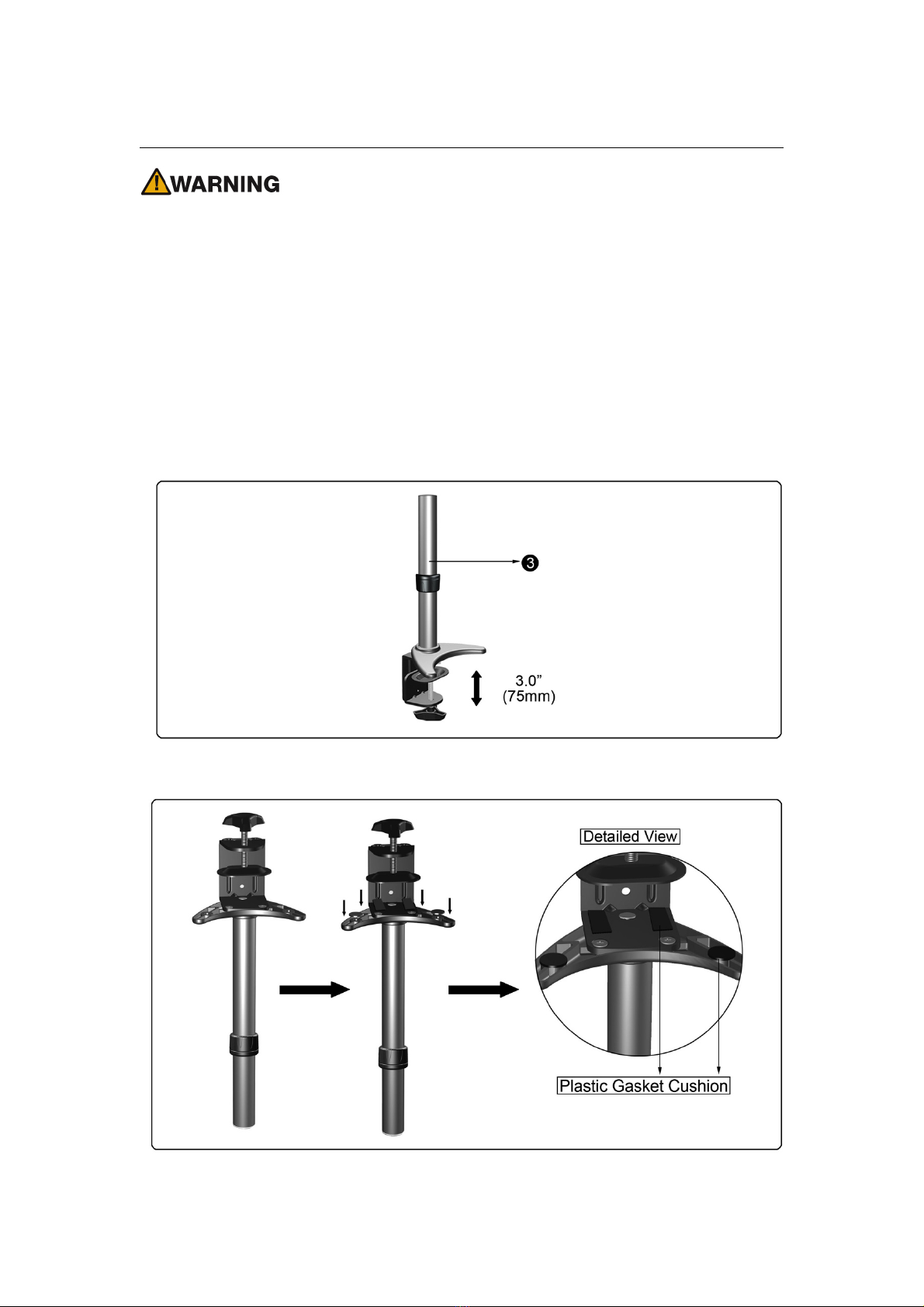

!Determine approximate location for mounting and keeping in mind the display size,

extension, height adjustment and pitch / roll requirements.

!This product contains small item, keep these items away from children

!Do not exceed the maximum weight capacity for this product. Exceeding the weight

capacity can result in serious personal injury or damage to equipment!