U S E R G U I D E |U V C - 5 C O N V E Y O R 4

Regulation), VBG (Administrative and Professional

Association), VDE (Association for electrical

engineering) etc. must be observed as well.

However, this device may constitute a hazard if

used improperly by unqualified personnel or for a

purpose other than the intended one.

Only skilled electricians are allowed to work on the

electrical system or components in compliance with

the electro-technical rules (e.g. EN 60204, DIN VDE

0100/0113/0160). The operator has to make sure

that the electrical systems and equipment are

operated and maintained according to the

electrotechnical rules.

In general, it is not allowed to carry out work on

parts under voltage. The protection class of the

device may be IP00 for certain components (direct

contact with hazardous voltage is possible).

Use the device only if it is closed.

Fuses must not be repaired or bridged but only

replaced. Use only fuses according to the circuit

diagram or spare parts list.

Before carrying out repair or maintenance work,

check whether the system is deenergized using a

two-pole voltage tester. Identified defects on

electrical systems/equipment/components must be

eliminated immediately. If there is an acute danger,

the defective device / system must not be operated.

Transport and storage

Transport the device only if packed in the original or

in an appropriate packaging. In case of big devices,

it is recommended to use a transport base or a

pallet for transport.

Store the device in a dry place protected from the

effects of the weather. Avoid exposure of the device

to extreme heat and cold. Observe the transport

instructions in the operating manual.

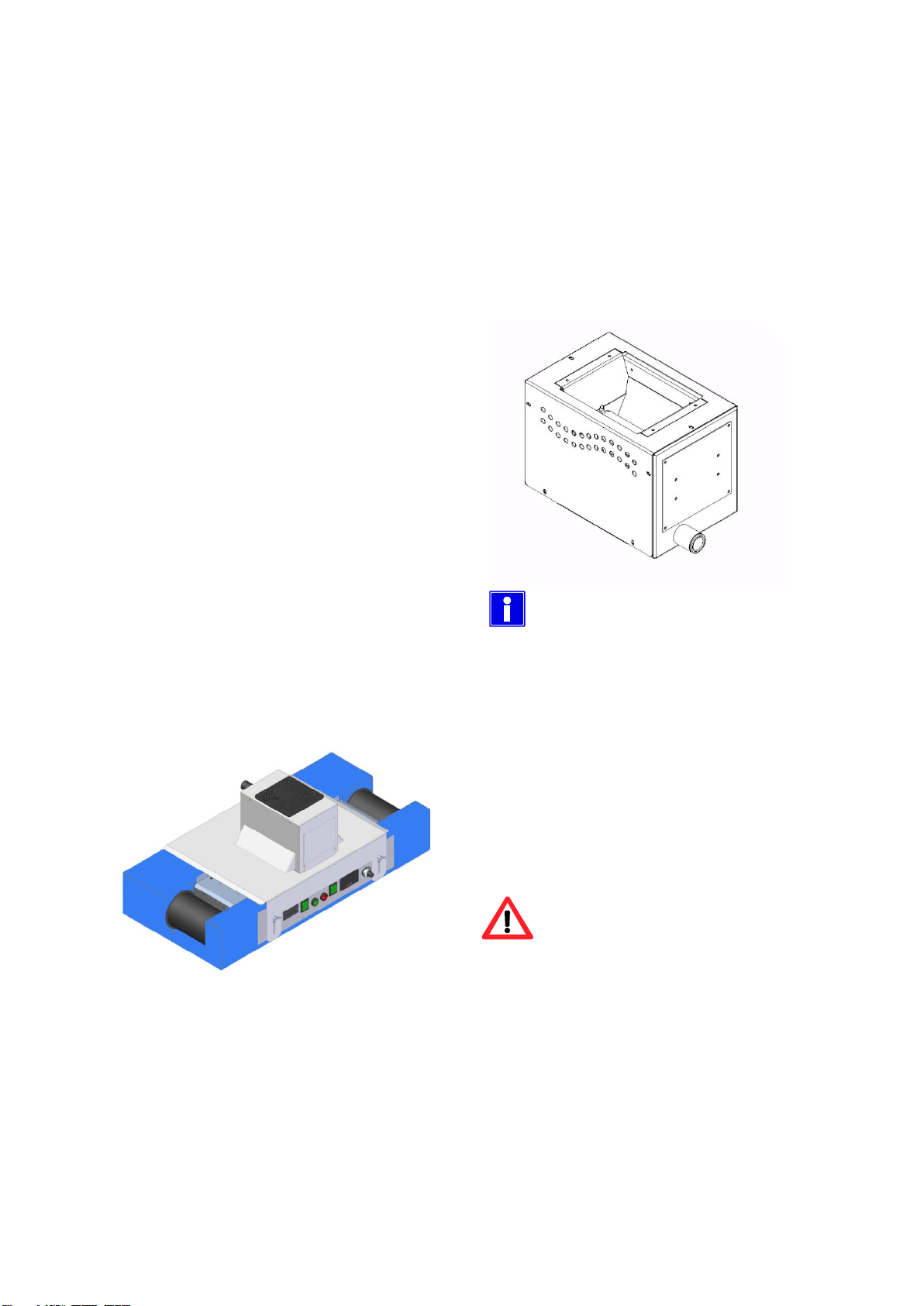

1. Important General

Information

1.1 Scope of Delivery

The scope of delivery includes:

•UV conveyor delivered as desktop device

•UV bulb included in the delivery (number and

doping according to the delivery note)

•Standard 2-meter connecting cable

•Technical documentation according to

order/performance specification

•EC Declaration of Conformity (A) according to

the EC Machinery Directive 2006/42/EC

•Various accessories (see delivery note)

•Safety goggles

Not included in the scope of delivery:

•Ductwork for supply and exhaust air

1.2 Responsibilities

In the following section, the different responsibilities

of the manufacturer and operator are defined.

1.2.1 Responsibilities of the

manufacturer

A risk assessment for this device has been

performed by the manufacturer and the result has

been documented according to DIN EN 12100. The

manufacturer delivers a device which complies with

the EC Machinery Directive 2006/42/EC dated

17 May 2006, appendix II A.

The concept and design of the device correspond

to the basic safety and health requirements of the

EC Machinery Directive; therefore, the device has

received the CE mark and declaration of conformity.

This declaration will cease to be valid if any

modification is made to the device without previous

consultation and consent of Dymax Europe GmbH.

The signed declaration of conformity is a part of this

operating manual, the CE mark has been placed

near the rating plate of the system.