Contents

Introduction..............................................................................................................................................4

Introduction to the User Guide ................................................................................................................................4

Where to Get Help ...................................................................................................................................................4

Safety........................................................................................................................................................4

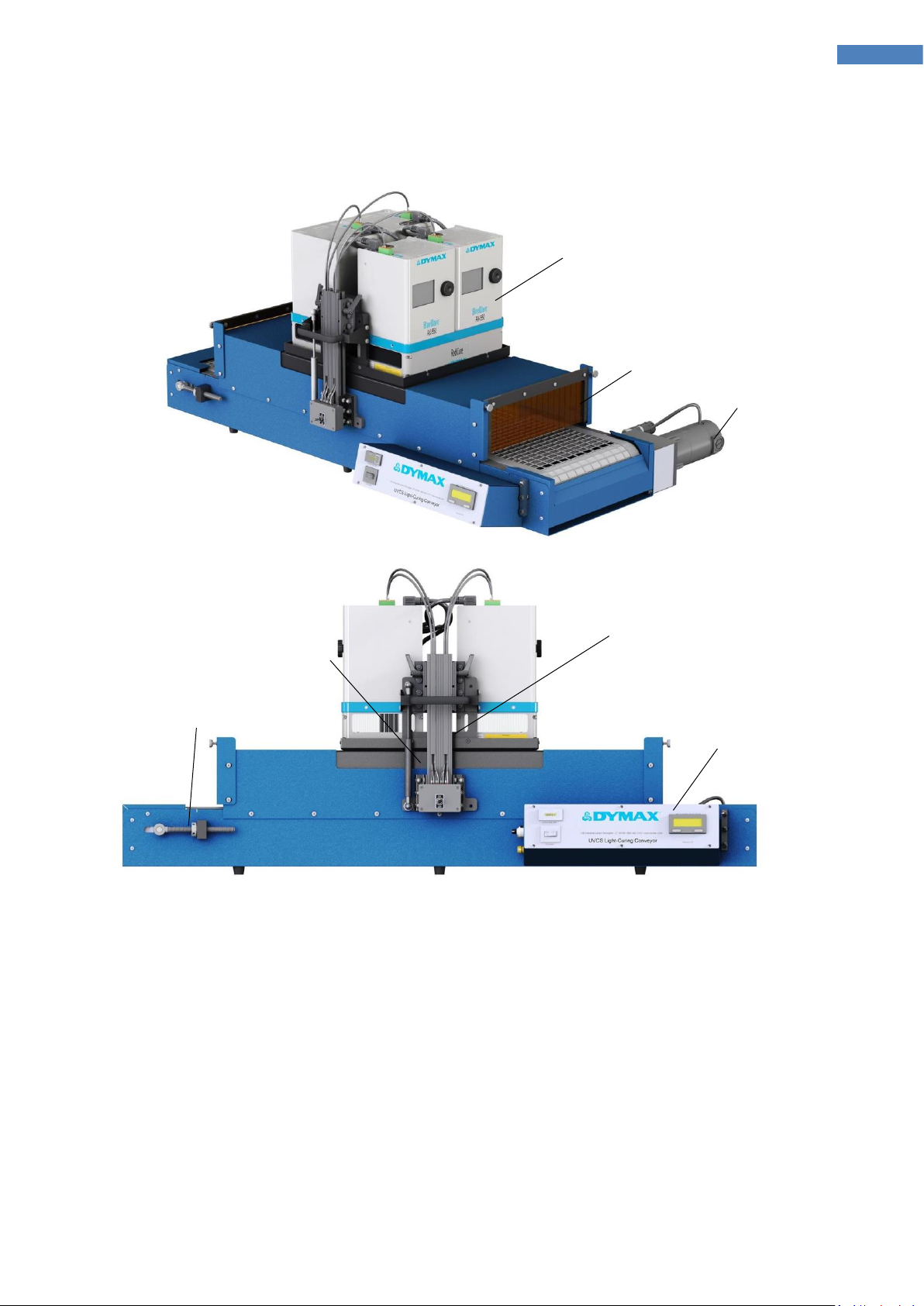

Product Overview .....................................................................................................................................5

Description of UVCS LED Light-Curing Conveyors..................................................................................................... 5

Assembly and Setup..................................................................................................................................6

Unpacking and Inspecting Your Shipment................................................................................................................6

Parts Included........................................................................................................................................................... 6

Setup ........................................................................................................................................................8

Conveyor Setup ........................................................................................................................................................ 8

Flood System Installation ......................................................................................................................................... 9

Wiring LED Control Switch......................................................................................................................................15

Operating the Conveyor..........................................................................................................................18

LED System Height Adjustment.............................................................................................................................. 19

Operating the LED Light ..........................................................................................................................21

Operating Modes.................................................................................................................................................... 21

Adjusting Intensity..................................................................................................................................................21

LED Operation ........................................................................................................................................................ 21

Validation ...............................................................................................................................................................22

Cleaning and Maintenance .....................................................................................................................22

Belt-Tracking Adjustment.......................................................................................................................................22

Conveyor Belt Replacement................................................................................................................................... 22

Inspect and Replace Fuses......................................................................................................................................24

Glass Cleaning......................................................................................................................................................... 24

Troubleshooting......................................................................................................................................25

Spare Parts and Accessories....................................................................................................................26

Options/Accessories...............................................................................................................................................26

Spare/Replacement Parts.......................................................................................................................................27

Specifications..........................................................................................................................................28

Definition of Terms .................................................................................................................................29

Warranty ................................................................................................................................................30

Index.......................................................................................................................................................31