Contents

Introduction......................................................................................................... 4

Where to Get Help ............................................................................................4

Safety................................................................................................................... 4

Product Overview................................................................................................. 5

Network Data Formats......................................................................................5

Unpacking ............................................................................................................ 5

Parts Included ...................................................................................................5

Connections ......................................................................................................... 6

Input Power.......................................................................................................7

Interlocks...........................................................................................................7

Emitters 1-4.......................................................................................................9

Ethernet Port.....................................................................................................9

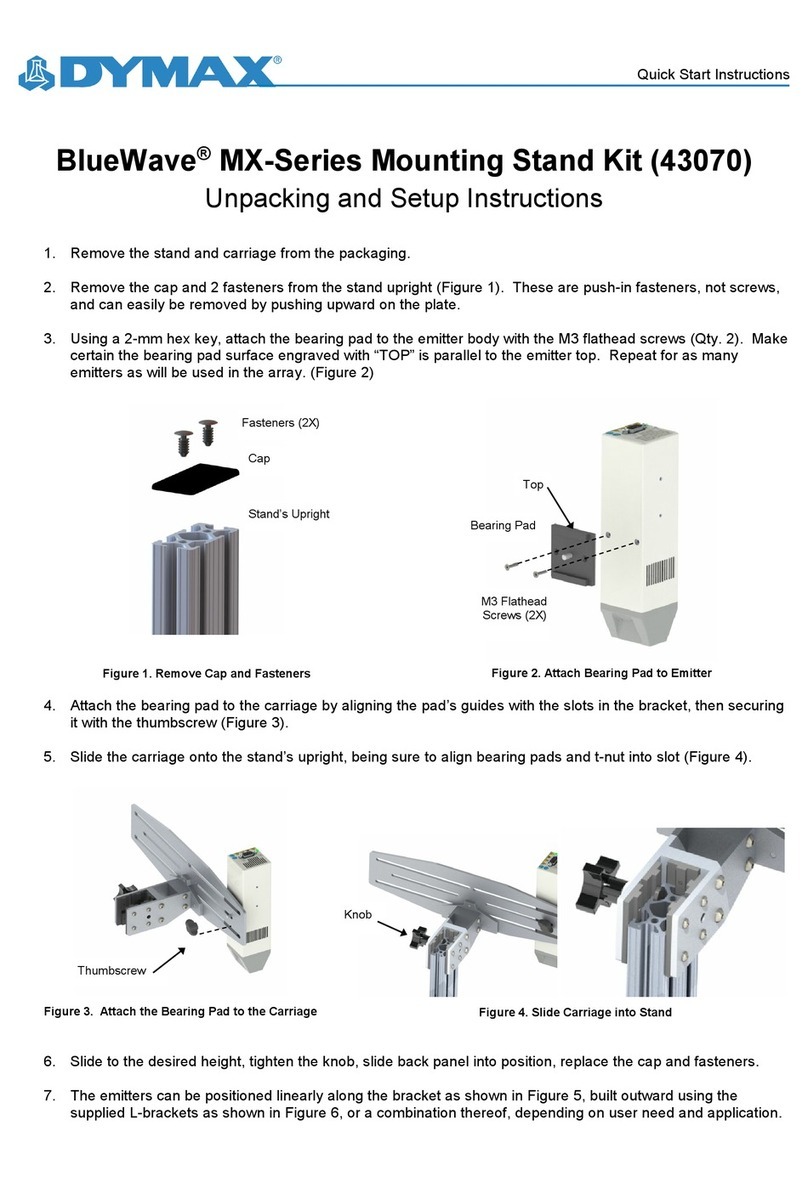

Installation......................................................................................................... 10

DIN Rail Mounting (Grounded) .......................................................................10

Factory Reset Button.......................................................................................... 14

Set Up & Web Interface Access........................................................................... 15

Controlling Emitters via the Web Interface.....................................................15

EtherNet/IP........................................................................................................ 18

PROFINET........................................................................................................... 21

Web Guide ......................................................................................................... 23

Log In Page......................................................................................................23

Main Page .......................................................................................................23

Network Configuration Page...........................................................................24

Diagnostics Alarm Log Page ............................................................................25

Diagnostics Page .............................................................................................27

Emitter Control Page.......................................................................................30

Configuration Mode........................................................................................31

Troubleshooting................................................................................................. 41

Parts and Accessories ......................................................................................... 44

Specifications ..................................................................................................... 45

Warranty............................................................................................................ 46