About Dymax

Light-curable adhesives. Systems for light curing, fluid

dispensing, and fluid packaging.

Dymax manufactures industrial adhesives, light-curable

adhesives, epoxy resins, cyanoacrylates, and activator-cured

adhesives. We also manufacture a complete line of manual fluid

dispensing systems, automatic dispensing systems, and light-

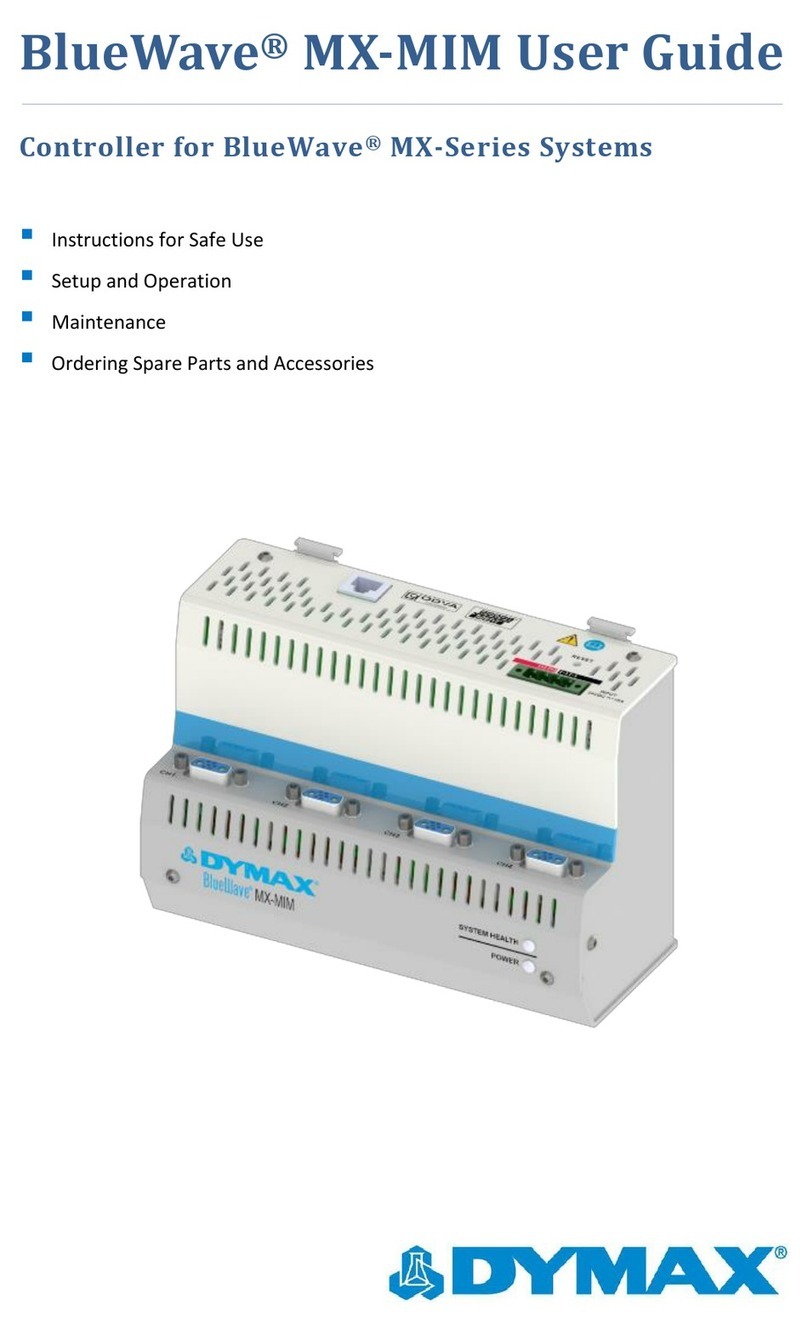

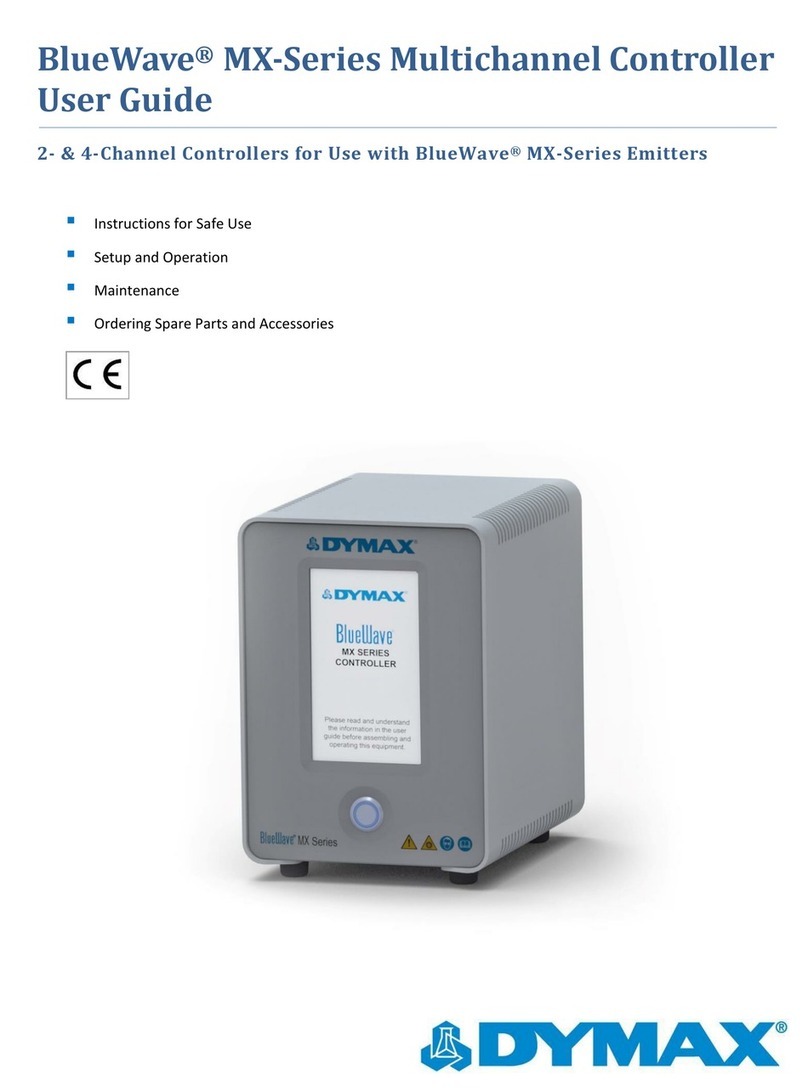

curing systems. Light-curing systems include LED light sources,

spot, flood, and conveyor systems designed for compatibility

and high performance with Dymax adhesives. Dymax adhesives

and light-curing systems optimize the speed of automated

assembly, allow for 100% in-line inspection, and increase

throughput. System designs enable stand-alone configuration

or integration into your existing assembly line.

Please note that most dispensing and curing system

applications are unique. Dymax does not warrant the fitness of

the product for the intended application. Any warranty

applicable to the product, its application, and use is strictly

limited to that contained in the Dymax standard Conditions of

Sale. Dymax recommends that any intended application be

evaluated and tested by the user to ensure that desired

performance criteria are satisfied. Dymax is willing to assist

users in their performance testing and evaluation. Data sheets

are available for valve controllers or pressure pots upon

request.