Minarik PCM3 User manual

USER’S MANUAL

PROCESS CONTROL

MODULE PCM3

Copyright 2002 by

Minarik Corporation

All rights reserved. No part of this manual may be reproduced or transmitted in

any form without written permission from Minarik Corporation. The information

and technical data in this manual are subject to change without notice. Minarik

Corporation and its Divisions make no warranty of any kind with respect to this

material, including, but not limited to, the implied warranties of its merchantability

and fitness for a given purpose. Minarik Corporation and its Divisions assume no

responsibility for any errors that may appear in this manual and make no

commitment to update or to keep current the information in this manual. MVD061402

Printed in the United States of America.

i

Safety Warnings

• This symbol denotes an important safety tip or warning.

PLEASE READ THESE INSTRUCTIONS CAREFULLY before

performing any of the procedures contained in this manual.

• DO NOT INSTALL, REMOVE, OR REWIRE THIS EQUIPMENT

WITH POWER APPLIED. Have a qualified electrical

maintenance technician install, adjust, and service this

equipment. Follow the National Electrical Code (NEC) and all

other applicable electrical and safety codes, including the

provisions of the Occupational Safety and Health Act (OSHA)

when installing equipment.

• Reduce the chance of an electrical fire, shock, or explosion by

proper grounding, over current protection, thermal protection, and

enclosure. Follow sound maintenance procedures.

S

H

OCK

HAZARD

AV

O

I

D

HEAT

KEE

DR

O

I

D

A

TI

ON

Although this process control module isolates a voltage or

current signal, its internal circuit potentials are at 115 VAC

or 230 VAC above earth ground. Avoid direct contact with

the printed circuit board or with circuit elements to prevent

the risk of serious injury or fatality. Use a non-metallic

screwdriver for adjusting the calibration trimpots.

ii

Contents

Safety Warnings i

Specifications 1

Dimensions 2

Introduction 3

Installation 4

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Shielding guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Screw terminal block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

AC line connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Voltage follower connection . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Current follower connection . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Leader signal generator connections . . . . . . . . . . . . . . . . . . . . .12

Output Voltage Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Armature Voltage Follower . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Multiple Follower Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Voltage/Current Selector Slide Switch . . . . . . . . . . . . . . . . . . . .20

Calibration 21

Voltage Signal Follower Calibration . . . . . . . . . . . . . . . . . . . . . .22

Manual Leader Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Current Signal Follower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

1-5 mA DC current signal input range: . . . . . . . . . . . . . . . . . . . . . . . .24

4-20 mA DC current signal input range: . . . . . . . . . . . . . . . . . . . . . . .25

10-50 mA DC current signal input range: . . . . . . . . . . . . . . . . . . . . . .26

Troubleshooting 28

Certificate of Compliance 31

Unconditional Warranty inside back cover

iii

Figure 1. Process Control Module Dimensions . . . . . . . . . . . . . . . . . .2

Figure 2. Screw Terminal Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Figure 3. 115VAC Power Connection . . . . . . . . . . . . . . . . . . . . . . . . .8

Figure 4. 230VAC Power Connection . . . . . . . . . . . . . . . . . . . . . . . . .9

Figure 5. Connection – Following an External Voltage Signal . . . . . . .10

Figure 6. Connection – Following an External Current Signal . . . . . . .11

Figure 7. Connection – Unidirectional Manual Leader Signal Source .13

Figure 8. Connection – Output Voltage . . . . . . . . . . . . . . . . . . . . . . . .15

Figure 9. Armature Voltage Follower Connections . . . . . . . . . . . . . . .17

Figure 10. Multiple Follower Motors Connection . . . . . . . . . . . . . . . .19

Figure 11. Voltage/Current Selectro Slide Switch . . . . . . . . . . . . . . . .20

Figure 12. Calibration Trimpot Layout . . . . . . . . . . . . . . . . . . . . . . . .21

Figure 13. Shunt Resistor Installation . . . . . . . . . . . . . . . . . . . . . . . .27

iv

Illustrations

1

Specifications

Power Requirements

Line input 115VAC/230 VAC, 50/60 Hz, single phase

Input Signal Ranges (input circuit is isolated)

Voltage signal, narrow range 0 to +25 VDC

Voltage signal, mid range 0 to +120 VDC

Voltage signal, wide range 0 to +550 VDC

Current signal 1–5 mADC, 4–20 mADC, 10–50 mADC

Input Impedance

Voltage signal >25K ohms

Current signal, 1–5 mADC 1K ohms

Current signal, 4–20 mADC 235 ohms

Current signal, 10–50 mADC 100 ohms

Output

Impedance 800 ohms

Voltage range, max 0 to +10 VDC

Linearity 0.1%

Operating Temperature Range 0 – 50 °C

2

Dimensions

CU

RREN

T

5

4

3

2

1

6

7

8

9

10

TP

IC

1

IC2

C

1

C2

C3

C4

C5

T1

P1

TB1

OC

1

MAXIMUM

OU

TP

UT

MINIMUM

OU

TP

UT

P2

P

3

MINARIK

ELE

C

TRI

C

S

I

G

NA

L

ISO

LAT

O

R

R1

R2

R

3

REF

OUT

2.700 [69]

2.150 [55]

4.225 [107]

4.825 [123]

MOUNTING HOLE (4 EA)

0.146 [4] DIAMETER 0.250 [6]

1.280 [33]

Figure 1. Process Control Module Dimensions

ALL DIMENSIONS IN INCHES [MILLIMETERS]

Minarik model PCM3 signal isolators produce a floating DC voltage

signal proportional to a variable DC current or voltage signal input.

It also can generate the floating DC voltage signal output controlled

by an external potentiometer. The output signal fed to a speed

controller allows a motor to be driven automatically at a speed

proportional to the signal, i.e., to follow the signal. The maximum

PCM3 output voltage is 10 VDC.

The PCM3 DC voltage output must be trimmed to not exceed the

reference voltage, i.e., the normal voltage drop across the speed

adjust potentiometer of the motor speed controller. For Minarik

MM20000 series controls, the reference voltage is approximately

3.5 VDC. Putting higher DC voltage into the control speed adjust

circuit will not produce correspondingly higher motor speeds. Such

an error can seriously degrade the linearity between the process

signal level and motor speed.

This manual contains specifications, installation procedures,

connections, and calibration procedures for the process control

module, model PCM3. Refer to your variable speed drive user’s

manual for additional installation, operation, and troubleshooting

procedures.

3

Introduction

4

Mounting

•PCM3 components are sensitive to electrostatic fields. Avoid

contact with the circuit board directly.

•Protect the PCM3 from dirt, moisture, and accidental contact.

•Provide sufficient room for access to the terminal block.

•Mount the PCM3 away from other heat sources. Operate within

the specified ambient operating temperature range. The

operating temperature range for the PCM3 is 0°C through 50°C.

•Prevent loose connections by avoiding excessive vibration of the

process control module board.

•Mount the PCM3 in either a horizontal or vertical plane. The

PCM3 is mounted using 4 ea. 0.25 inch [6mm] standoffs.

See Figure 1, page 2 for the physical locations of these

standoffs. Use #8 panhead screws to fasten the standoffs to the

mounting surface.

Installation

Warning

Do not install, rewire, or remove this control with input power

applied. Doing so may cause fire or serious injury. Make

sure you read and understand the Safety Warnings on page

i before attempting installation.

5

Installation

•Use 18-24 AWG wire for speed adjust potentiometer wiring. Use

14–16 AWG wire for AC line (L1, L2) and motor (A1 and A2)

wiring.

Wiring

Warning

Do not install, rewire, or remove this control with input power

applied. Failure to heed this warning may result in fire,

explosion, or serious injury.

This drive is isolated from earth ground. Circuit potentials

are at 115 or 230 VAC above ground. To prevent the risk of

injury or fatalisty, avoid direct contact with the printed circuit

board or with circuit elements.

Do not disconnect any of the motor leads from the drive

unless power is removed or the drive is disabled. Opening

any one motor lead may destroy the drive.

쇵

6Installation

As a general rule, Minarik recommends shielding of all conductors.

If it is not practical to shield power conductors, Minarik

recommends shielding all logic-level leads. If shielding is not

practical, the user should twist all logic leads with themselves to

minimize induced noise.

It may be necessary to earth ground the shielded cable. If noise is

produced by devices other than the PCM module, ground the

shield at the module end. If noise is generated by a device on the

PCM module, ground the shield at the end away from the PCM

module. Do not ground both ends of the shield.

If the module continues to pick up noise after grounding the shield,

it may be necessary to add AC line filtering devices, or to mount

the PCM module in a less noisy environment.

Logic wires from other input devices, such as motion controllers

and PLL velocity controllers, must be separated from power lines in

the same manner as the logic I/O on this drive.

Shielding guidelines

Warning

Under no circumstances should power and logic leads be

bundled together. Induced voltage can cause unpredictable

behavior in any electronic device, including motor controls.

7

Screw terminal block

Connections to Minarik’s PCM3 are made to a screw terminal

block. Using a screwdriver, turn the terminal block screw counter-

clockwise to open the wire clamp. Insert stripped wire into the wire

clamp. Turn the terminal block screw clockwise to clamp the wire.

See Figure 2.

Figure 2. Screw Terminal Block

Installation

8Installation

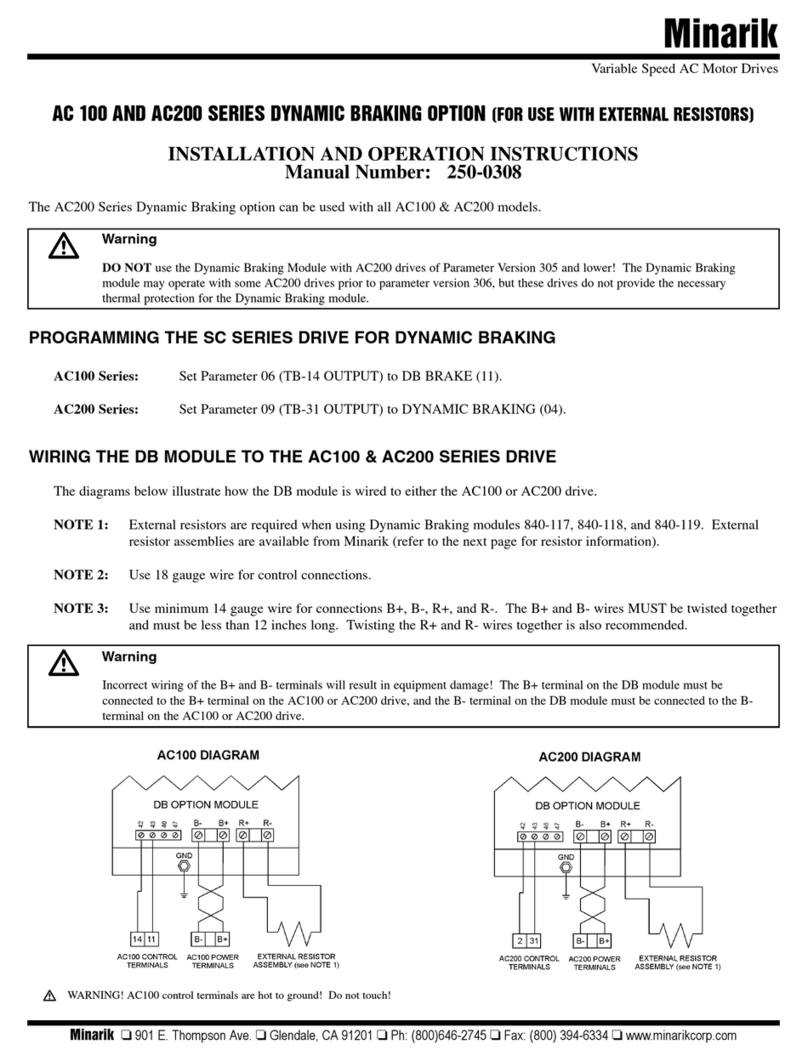

AC line connections

Connect AC power leads to terminals 1 and 4. When operating on

115VAC, leave the jumper bars installed between terminals 1 and 2

and between 3 and 4 (see Figure 3). This is the PCM3’s default

(factory) setting. When operating on 230VAC, remove both

jumper bars and place one jumper bar between terminals 2 and 3

(see Figure 4, page 9).

CU

RREN

T

5

6

7

8

9

10

TP

IC

1

IC2

C

1

C2

C3

C4

C5

T1

P1

TB1

OC

1

MAXIMUM

OU

TP

UT

MINIMUM

OU

TP

UT

P2

P

3

MINARIK

ELE

C

TRI

C

S

I

G

NA

L

ISO

LAT

O

R

R1

R2

R

3

A

C

P

O

WER

1

1

5

VA

C

INP

UT

1

4

JU

MPER BAR

S

IN

S

TALLE

D

BETWEEN TERMINALS 1 & 2

AND TERMINALS 3 & 4

Figure 3. 115VAC Power Connection

9

Installation

Figure 4. 230VAC Power Connection

CU

RREN

T

5

6

7

8

9

10

TP

IC

1

IC2

C

1

C2

C3

C4

C5

T1

P1

TB1

OC

1

MAXIMUM

OU

TP

UT

MINIMUM

OU

TP

UT

P2

P

3

MINARIK

ELE

C

TRI

C

S

I

G

NA

L

ISO

LAT

O

R

R1

R2

R

3

A

C

P

O

WER

230

VA

C

INP

UT

1

4

JU

MPER BAR IN

S

TALLE

D

BETWEEN TERMINALS 2 & 3

10

Voltage follower connection

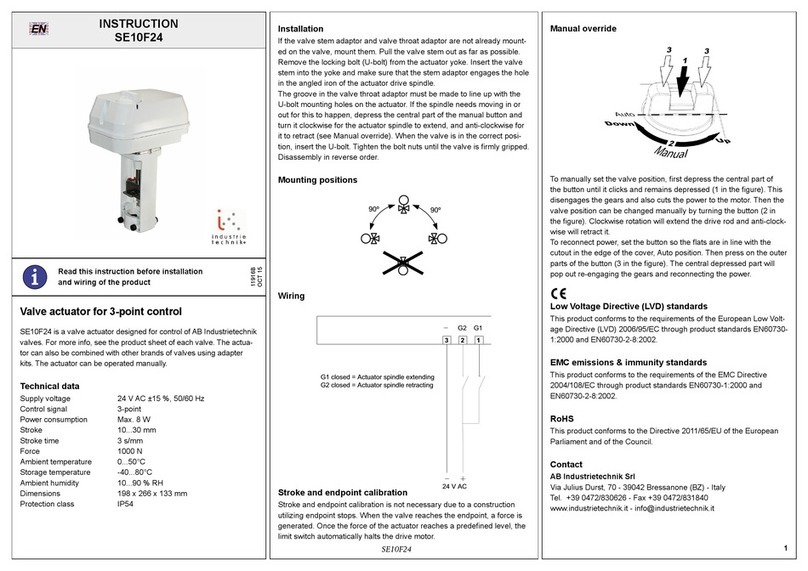

(1) Set the Current/Voltage Switch to Voltage.

(2) Connect the incoming voltage signal leads as shown in Figure

5 below.

(3) Connect the negative lead to Terminal 5.

(4) If the voltage signal is less than 20VDC, connect the positive

lead to Terminal 6. If the voltage signal is less than 120VDC,

connect the positive lead to Terminal 7. If the voltage signal is

greater than 120VDC, connect the positive lead to Terminal 8.

V

O

LTA

GE

CU

RREN

T

5

4

3

2

1

0

- 2

0

VD

C

V

O

LTA

GE

S

I

G

NA

L

6

7

8

9

10

INPUT

TP

P1

MAXIMUM

OU

TP

UT

MINIMUM

OU

TP

UT

P2

P

3

R1

R2

R

3

0

- 12

0

VD

C

V

O

LTA

GE

S

I

G

NA

L

REF

(

+

)

REF

(

+

)

0

-

550

VD

C

V

O

LTA

GE

S

I

G

NA

L

REF

(

+

)

CU

RRENT

/

V

O

LTA

GE

S

WIT

CH

CO

M

(

-

)

Figure 5. Connection – Following an External Voltage Signal

Installation

11

Current follower connection

(1) Set the Current/Voltage Switch to Current.

(2) Connect the incoming current signal leads as shown in Figure

6 below.

(3) Connect the negative lead to Terminal 5.

(4) Connect the positive lead to Terminal 6.

V

O

LTA

GE

CU

RREN

T

5

4

3

2

1

CU

RREN

T

F

O

LL

O

WER INP

UT

COM

(

-

)

REF

(

+

)

6

7

8

9

10

INPUT

TP

P1

MAXIMUM

OU

TP

UT

MINIMUM

OU

TP

UT

P2

P

3

R1

R2

R

3

CU

RRENT

/

V

O

LTA

GE

S

WIT

CH

8

Figure 6. Connection – Following an External Current Signal

Installation

12 Installation

Leader signal generator connections

The PCM3 can be used as a leader controller in one of two ways.

It can provide a floating DC leader voltage input to other PCM3

modules interfacing with standard variable speed drives.It can also

drive several variable speed drives directly, provided that their

circuit design permits wiring of their speed circuits in common.

Unidirectional applications require a positive PCM3 output. Connect

a 10K ohm potentiometer (not provided with the PCM3) as the

leader control pot using the +10 VDC REF OUT supply on the

PCM3. Refer to Figure 7 (page 13).

To connect an external leader control potentiometer, attach the CW

side of the potentiometer to the REF OUT terminal. The

potentiometer wiper is connected to terminal 6. The CCW terminal

is connected to terminal 5.

13

Figure 7. Connection – Unidirectional Manual Leader Signal Source

V

O

LTA

GE

CU

RREN

T

5

4

3

2

1

10

K

O

H

M

S

PEED AD

JUST

P

O

TENTI

O

METER

C

W

6

7

8

9

10

INPUT

TP

IC

1

IC2

C

1

C2

C3

C4

C5

T1

P1

TB1

REF OUT

OC

1

MAXIMUM

OU

TP

UT

MINIMUM

OU

TP

UT

P2

P

3

MINARIK

ELE

C

TRI

C

S

I

G

NA

L

ISO

LAT

O

R

R1

R2

R

3

Installation

14 Installation

Most Minarik controls have positive reference voltage across the

speed adjust pot with respect to the CCW side. The pot wiper

position determines the fraction of this control reference voltage

that will be applied to the speed adjustment circuit.

In these controls, the application of a positive voltage at the wiper

with reference to the CCW connection will cause the motor to run.

Output connections are made to terminals 9 and 10 of terminal

board TB501. Connect the negative lead to terminal 9. Connect

the positive lead to terminal 10. Refer to Figure 8 (page 15).

Some controls have a negative reference voltage across the speed

adjust pot. Reverse the polarity of the connection to such controls.

Output Voltage Connections

Warning

Always check the instruction manual supplied with the

variable speed drive that will be interfaced with the PCM3

module. The scheme shown for wiring to an external

voltage source, as well as the specifications on that input,

must be well understood before proceeding.

Table of contents

Other Minarik Controllers manuals

Popular Controllers manuals by other brands

Minebea Intec

Minebea Intec Maxxis 5 Original installation manual

Motoman

Motoman XRC Series manual

TOPP

TOPP C160RWA Installation and use instructions

Special Stage Systems

Special Stage Systems MING MECCA user guide

Moog Videolarm

Moog Videolarm VLC485 Installation and operation instructions

Autonics

Autonics TF3 Series user manual

EUROSTER

EUROSTER 12 Installation and operation manual

Autonics

Autonics TC4Y manual

Automated Logic

Automated Logic RC642 Technical instructions

Prolon

Prolon C1000 Series quick start guide

Siko

Siko AG25 Translation of the original installation instructions

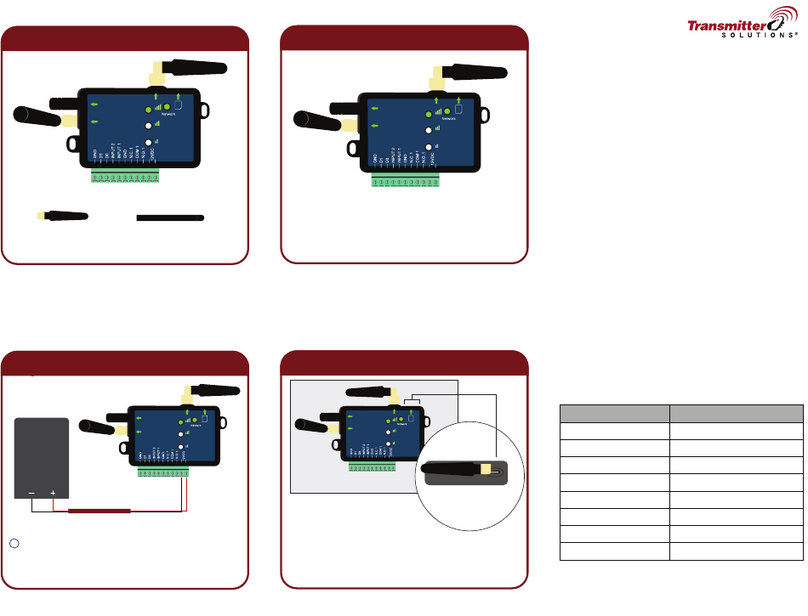

Transmitter Solutions

Transmitter Solutions PAL SPIDER WIEGAND 26 quick start guide