OSKAR ratiotherm rZR16x2 Technical manual

Technical document

Central controller rZR16x2

Version 15.06.2021-wi

0 - 10V

Auto - O - Hand

I

O

230V

Hand - O - Auto

Netz

TU_Central controller 16x2-2021-06-wi - Errors and omissions excepted. All informaon, pictures and drawings are subject to change.

Compliance with the generally applicable and recognised rules of technology must be observed at all mes!

CAUTION: Installaon and wiring may only be carried out by authorised specialists.

2

TABLE OF CONTENTSTABLE OF CONTENTS

SENSOR 4

OPTIONAL ACCESSORIES 5

TECHNICAL DATA 6

MOUNTING THE CONTROLLER CONSOLE 7

ASSEMBLY / DISASSEMBLY OF THE CONTROLLER 8

SENSOR POSITIONING IN THE VERTICAL IMMERSION SLEEVE 9

SENSOR POSITIONING FOR HOT WATER PREPARATION 10

WIRING THE COMPONENTS 12

WIRING THE COMPONENTS 13

OVERVIEW OF THE OUTPUTS 14

MOTHERBOARD/PLATE UPPER SECTION 15

Standard programming 18

Inputs (node 1) for standard hydraulics V4/04 19

Outputs (node 1) for standard hydraulics V4/04 20

DL inputs 21

CABLE SELECTION AND NETWORK TOPOLOGY 22

HYDRAULIC CALIBRATION OF THE SOLAR COMPACT STATION SOK 34

PROBLEM SOLVING 46

PROBLEM SOLVING 47

RATIOTHERM SERVICE CONSIGNMENT NOTE 48

GUARANTEE STATEMENT 49

3

TU_Central controller16x2-2021-06-wi - Errors and omissions excepted. All informaon, pictures and drawings are subject to change.

Compliance with the generally applicable and recognised rules of technology must be observed at all mes!

CAUTION: Installaon and wiring may only be carried out by authorised specialists.

SAFETY REGULATIONS

intended exclusively for authorised specialists.

when it is de-energised.

Use contrary to the intended purpose leads to the exclusion of any liability claims.

•

•

•

•

•

•

•

•

•

• -

-

tened with gentle alcohol (e.g. spirit) should be used for cleaning.

The unit therefore has no adjustment facility.

Thus, a possible adjustment is not necessary.

Any repair must not alter the design features of the appliance. Spare parts must corres-

pond to the original spare parts and must be used again in accordance with the factory

TU_Central controller 16x2-2021-06-wi - Errors and omissions excepted. All informaon, pictures and drawings are subject to change.

Compliance with the generally applicable and recognised rules of technology must be observed at all mes!

CAUTION: Installaon and wiring may only be carried out by authorised specialists.

4

SENSOR

• PT 1000 B (-40 bis +180°C)

• 5 m Silicone cable

• Sensor Ø 5,5 mm

Collector sensor

• PT 1000 B (-40 bis +180°C)

• 2,5 m Silicone cable

• Sensor Ø 5,5 mm

• Surge protecon

Pipe contact sensor

• PT 1000 B (-40 bis +180°C)

• 5,0 m Silicone cable

• Fastening clamp

• Heat-conducng paste

• PT 1000 B (-40 bis +180°C)

• 5 m PVC-Cable

• Brass screw-in part ½“ AG

Outdoor sensor

• PT 1000 B (-40 bis +180°C)

• Surge protecon

5

TU_Central controller16x2-2021-06-wi - Errors and omissions excepted. All informaon, pictures and drawings are subject to change.

Compliance with the generally applicable and recognised rules of technology must be observed at all mes!

CAUTION: Installaon and wiring may only be carried out by authorised specialists.

OPTIONAL ACCESSORIES

Room setpoint adjuster RSG-Plus

• DL bus device

• Potenometer (±5°C)

• Operang mode selector switch

Room remote control

•

unit for room temperature, humidity and air pressure.

Extension module RSM 610

•• with 6 inputswith 6 inputs

•• with 6 outputs (switching output or mixer control) with 6 outputs (switching output or mixer control)

•• with 4 outputs (0-10 Volt or PWM) with 4 outputs (0-10 Volt or PWM)

•• with sensors as requiredwith sensors as required

C.M.I. Modul

• The C.M.I. (Conrol and Monitoring Interface) is an interface for the comfortable

remote control, data logging and visualisaon of all ra controllers with a

of all ra controllers with DL or CAN bus.

Electronic volume flow sensor EVS

•• DN 10: ow rates between 2.0 and 32 litres per min.DN 10: ow rates between 2.0 and 32 litres per min.

•• DN 15: ow rates between 4.0 and 50 litres per min.DN 15: ow rates between 4.0 and 50 litres per min.

•• DN 20: ow rates between 5.0 and 85 litres per min.DN 20: ow rates between 5.0 and 85 litres per min.

•• DN 25: ow rates between 9.0 and 150 litres per min.DN 25: ow rates between 9.0 and 150 litres per min.

•• Detecon of medium temperatures from -40 to +125°C (PT1000)Detecon of medium temperatures from -40 to +125°C (PT1000)

•• Output of the measured values via DL busOutput of the measured values via DL bus

Volume flow pulse transmitter VIG1 or VIG2

•• Impeller meter for exact recording of the volumetric ow with Impeller meter for exact recording of the volumetric ow with

pulse output.pulse output.

•• Temperature range up to 90°C Temperature range up to 90°C

•• Pulse output potenal-free - maximum load 10 mA for rZR16x2 for exact heat Pulse output potenal-free - maximum load 10 mA for rZR16x2 for exact heat

quanty measurement e.g. of a solar systemquanty measurement e.g. of a solar system

TU_Central controller 16x2-2021-06-wi - Errors and omissions excepted. All informaon, pictures and drawings are subject to change.

Compliance with the generally applicable and recognised rules of technology must be observed at all mes!

CAUTION: Installaon and wiring may only be carried out by authorised specialists.

6

TECHNICAL DATA

All inputs

Temperature sensors of the types PT1000 (standard sensor for ratiotherm), KTY 10 (2 kΩ/25°C),

KTY 10 (1 kΩ/25°C), PT100, PT500, Ni1000, Ni1000TK5000 and room sensors RAS or RASPT,

radiation sensor GBS01, thermocouple THEL, humidity sensor RFS, rain sensor RES01,

pulses max. 10 Hz, voltage up to 3.3V DC, resistance (1-100kΩ), and as digital input

Entrance 7 addional voltage (0-10 Volt DC)

Entrance 8 addional current loop (4-20 mA DC), voltage (0-10 volts DC)

Entrance 15, 16 Addional pulse input max. 20 Hz, e.g. for volumetric ow transmier VIG or SO signals

To avoid uctuaons in the measured values, ensure that the sensor cables are not exposed to

external negave inuences from 230V cables to ensure interference-free signal transmission. The

sensor lines must not be routed together with the mains voltage in one cable. If unshielded cables are

a minimum distance of 5 cm. Sensor lines for PT100 or PT500 sensors must be shielded. All sensor

Outputs

1, 2, 3, 4, 6, 7, 8, 9, 10, 11 Relay outputs, parally NC and NO (max. switching capacity 230 volts / 3 amps)

Relay change-over contact - potenal-free

Output 12, 13, 14, 15, 16 Analogue outputs 0-10 volts (max. 20 mA) or PWM (10V/1kHz)

or expansion opon as switching outputs via addional relay (ma. 3A)

max. Buslast (DL-Bus) 100%

CAN-Bus Standard data rate 50 kbit/s, adjustable from 5 to 500 kbit/s

with separate switch-on and switch-o dierence

with separate switch-on and switch-o dierence or with xed hysteresis

Temperature measuring range -49.9°C to +249.9°C with a resoluon of 0.1K

Accuracy temperature typ. 0.4K, max. ± 1K in the range of 0-100°C for PT 1000 sensors

typ. 1%, max. 5% of the maximum measuring range of the input

230 Volt, 50-60Hz, (outputs A1 to A11 and unit together fused with 6.3A fast)

Supply line 3 x 1mm² H05VV-F according to EN 60730-1

3.5 to 4 was, per acve switching output

The controller has a power reserve of approx. 3 days for the date and me in the event of a power

failure.

Permissible ambient temp. +5 to +45°C

IP 40 (controller and housing) = protected against solid foreign bodies with a diameter of 1.0 mm or

more; Protected against access with a wire; no protecon against water.

Probes / Sensors - Resistance values:

Temp. (C°)

-20 -10 010 20 25 30 40

PT1000 (Ω)922 961 1000 1039 1078 1097 1117 1155

Temp. (C°)

50 60 70 80 90 100 110 120

PT1000 (Ω)119 4 1232 1271 1309 1347 1385 1423 1461

7

TU_Central controller16x2-2021-06-wi - Errors and omissions excepted. All informaon, pictures and drawings are subject to change.

Compliance with the generally applicable and recognised rules of technology must be observed at all mes!

CAUTION: Installaon and wiring may only be carried out by authorised specialists.

MOUNTING THE CONTROLLER CONSOLE

Our sketches do not represent an exact image of the products.

Dimensions in millimetres (mm).

The console is to be xed to the wall at eye level (approx. 1.6 m) with the enclosed mounng material.

1

TU_Central controller 16x2-2021-06-wi - Errors and omissions excepted. All informaon, pictures and drawings are subject to change.

Compliance with the generally applicable and recognised rules of technology must be observed at all mes!

CAUTION: Installaon and wiring may only be carried out by authorised specialists.

8

ASSEMBLY / DISASSEMBLY OF THE CONTROLLER

Aer you have pushed the controller into the mounng sha of the

housing, connect it to the nut card by pressing rmly on the edge of the

controller.

Please do not put any pressure on the display.

To dismantle the controller, use 2 broad sloed screwdrivers to

carefully press in the two lateral detent claws of the regulator and

carefully lever out the regulator.

And carefully lever out the regulator.

1

The SD card is located in the lower edge area of the controller (1).

To make it easier to remove or insert the card,

the controller should be removed from the housing.

I

I

9

TU_Central controller16x2-2021-06-wi - Errors and omissions excepted. All informaon, pictures and drawings are subject to change.

Compliance with the generally applicable and recognised rules of technology must be observed at all mes!

CAUTION: Installaon and wiring may only be carried out by authorised specialists.

•

•

•

depth.

•

forTWK > Table p. 39

S2 (rUVR + rZR) for hot water

for TWK > Table p. 39

• Immersion sleeve of stainless steel with:

Immersion depth of the immersion tubes.

SENSOR POSITIONING IN THE VERTICAL IMMERSION SLEEVE

SE 1,0 / 1,5 1,0 / 1,5 1,0 / 1,5 1,0 / 1,5 1,0 / 1,5 1,0 / 1,5 1,0 / 1,5 5,0 5,0 5,0

Typ

400 750 1000 1300 2000 3000 4000 2000 3000 4000 mm

S3

500 500 500 500 500 500 600 500 500 600 mm

S3

800 800 800 800 800 800 900 mm

S11 1500 1500 1880 1700 1700 1500 2010 1700 1500 2010 mm

TU_Central controller 16x2-2021-06-wi - Errors and omissions excepted. All informaon, pictures and drawings are subject to change.

Compliance with the generally applicable and recognised rules of technology must be observed at all mes!

CAUTION: Installaon and wiring may only be carried out by authorised specialists.

10

Mass ow in the primary circuit (kg/s)

SENSOR POSITIONING FOR HOT WATER PREPARATION

Example: -10/1,5/750 oder 1000

•

•

•

• Flow rate: 25 l/min

•

from diagram:

• -

• -

•

• Washbasin tap: 10,5 l/min

• Bath faucet: 15,0 l/min

11

TU_Central controller16x2-2021-06-wi - Errors and omissions excepted. All informaon, pictures and drawings are subject to change.

Compliance with the generally applicable and recognised rules of technology must be observed at all mes!

CAUTION: Installaon and wiring may only be carried out by authorised specialists.

Sensor must be

immersed in

the medium ê

h

I

I

TU_Central controller 16x2-2021-06-wi - Errors and omissions excepted. All informaon, pictures and drawings are subject to change.

Compliance with the generally applicable and recognised rules of technology must be observed at all mes!

CAUTION: Installaon and wiring may only be carried out by authorised specialists.

12

WIRING THE COMPONENTS

PE

N

M

~

A7

S5

A13S

A13W

A13

I O II

I O II

entweder

Schalter

oder

0-10V

GND

GND

PE

N

M

~

A6

S8

GND

AUTOMATIC

HEAT GENERATOR

MANUAL

HEAT GENERATOR

PE

N

M

~

A3

PE

N

S13

T T

M

M

A8

A9

Auf

Zu

Aussenfühler

S4

GND

GND

PE

N

M

~

A4

PE

N

S14

M

A10

A11

Auf

Zu

M

TT

Aussenfühler

S4

GND

GND

HEATING CIRCUIT 1

LOW TEMPERATURE

HEATING CIRCUIT 2

HIGH TEMPERATURE

13

TU_Central controller16x2-2021-06-wi - Errors and omissions excepted. All informaon, pictures and drawings are subject to change.

Compliance with the generally applicable and recognised rules of technology must be observed at all mes!

CAUTION: Installaon and wiring may only be carried out by authorised specialists.

WIRING THE COMPONENTS

WR

T

T

Smart Energy

A5S

GND

PWM

0-10 V

A5W

TT

T T

000

∑

m

³

PE

N

M

~

A2

GND

GND

A15

A14 S9

PWM

0-10 V

PWM

0-10 V

blau = PWM -

braun = PWM +

S12

DL3/6

S10

GND

GND

GND

GND

DL3/2

AUTOMATIC

HEAT GENERATOR

MANUAL

HEAT GENERATOR

PE

N

M

~

A1

GND

A16

S6

PWM

0-10 V

blau = PWM -

braun = PWM +

PE

N

M

~

L

Zirkulation

S15

grün

weiss

braun

S7

GND

GND

GND

24V=

TT

KW

A1K32

A2K32

Honeywell

VC 4012

M

Auf Zu

N

Steuerphase

Nulleiter

Dauerphase

Nulleiter

Steuerphase

Erdung

Pumpe

A1K32

A2K32

M

M

Pumpe und Ventil

paralell angesteuert

M

~

DRINKING WATER

COMPACT STATION

RETRIEVAL AND STORAGE

2. BUFFER STORAGE

TU_Central controller 16x2-2021-06-wi - Errors and omissions excepted. All informaon, pictures and drawings are subject to change.

Compliance with the generally applicable and recognised rules of technology must be observed at all mes!

CAUTION: Installaon and wiring may only be carried out by authorised specialists.

14

OVERVIEW OF THE OUTPUTS

A1 A2 A3 A4 A5 A6 A7 A8+9 A10+11 A12 A13

N/PE N/PEN/PE N/PE W+S N/PE N/PE N/PE N/PE W+S W+S

M M

Zirkulation

Pumpe Pumpe Pumpe Pumpe Pumpe Pumpe Mischer Mischer

Solar Heizkreis 1 Heizkreis 2 SmartEnergy man. WE aut. WE Heizkreis 1 Heizkreis 2 Wärmep. aut. WE

Anford. Anford. Anford.

A14 A15 A16 IO66-A1S

N/PE

Primärkreis

Solar Pumpe

Solar

Auslagerung Rückladung

Pumpe

GND

PWM PWM

Sekundärk.

GND GND

Pumpe

TWK-Station

PWM

IO66-A2S

N/PE

15

TU_Central controller16x2-2021-06-wi - Errors and omissions excepted. All informaon, pictures and drawings are subject to change.

Compliance with the generally applicable and recognised rules of technology must be observed at all mes!

CAUTION: Installaon and wiring may only be carried out by authorised specialists.

MOTHERBOARD/PLATE UPPER SECTION

Zusatzrelais-Eingangschalter-Platine V1.1

BA150332

K32_A7

A12

A13

A14

A15

A16

Ausgangs-Wippschalter-Platine V1.1

BA150331

A7

A6

A5

A4

A3

A2

ratiotherm-Hauptplatine V1.1

CMI-Modul

(K56)

RSM 610

(K32)

rZR16x2

(K1)

Netz-

teil

Auto-0-Hand

Hand-0-Auto

Ladepumpe WE 1

Ladepumpe WE 2

Freigabe Smart Energy

Pumpe Solar (230V)

unbenutzt im Standard

WW-Anforderung (WP)

Anforderung WE 1

Solar Primärpumpe

Ladepumpe TWK

TU_Central controller 16x2-2021-06-wi - Errors and omissions excepted. All informaon, pictures and drawings are subject to change.

Compliance with the generally applicable and recognised rules of technology must be observed at all mes!

CAUTION: Installaon and wiring may only be carried out by authorised specialists.

16

Special features of the outputs

K1 A 12 / K1 A 13 / K 32 A 7

side.

-

+ 24 V

+ 12 V

S 1

S 2

S 3

S 4

S 6

S 7

S 8

S 9

S 10

S 11

S 12

S 13

S 14

S 16

NETZEINSPEISUNG

Standby-Spannung SOK

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

NETZSPANNUNG

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

P-230 V

P-230 V

A 1

A 2

A 3

A 4 S

A 4 Ö

L1 - 230 V

A 6

A 7

A 8

A 9

A 10

A 11 S

A 11 Ö

A 12 Ö

A 12 S

A 12 W

L1 - 230 V

A 13 Ö

A 13 S

A 13 W

L1 - 230 V

IO66_A1S

IO66_A2S

IO66_A3S

IO66_A4S

NETZ

NETZ

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K32

K32

K32

K32

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

A 12 PWM

A 13 PWM

A 14 PWM

A 16 PWM

OUT_A 7

OUT_A 8

OUT_A 9

OUT_A 10

IN1 = S 1

IN2 = S 2

IN3 = S 3

IN4 = S 4

IN6 = S 6

DL (Datenltg.)

DL 1

DL 2

CAN-H

CAN-L

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

IO66_A6Ö

IO66_A6S

IO66_A6W

� NETZ

� NETZ

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K32

K32

K32

K32

K1

K1

K1

K1

K1

K32

K32

K32

K32

K32

K32

K32

K32

K32

K32

K32

K1

K2

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

L1 - 230 V (Phase TWK)

PE

PE

PE

PE

PE

PE

PE

PE

PE

PE

PE

PE

PE

PE

PE

PE

PE

PE

PE

PE

PE

PE

PE

PE

PE

PE

IO66_A7Ö

IO66_A7S

IO66_A7W

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

� NETZ

� NETZ

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K32

K32

K32

K1

K1

K1

K1

K1

K32

K32

K32

K32

K32

K32

K32

K32

K32

K32

K32

K1

K1

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

-

17

TU_Central controller16x2-2021-06-wi - Errors and omissions excepted. All informaon, pictures and drawings are subject to change.

Compliance with the generally applicable and recognised rules of technology must be observed at all mes!

CAUTION: Installaon and wiring may only be carried out by authorised specialists.

Special features of the outputs

K1 A 12 / K1 A 13 / K 32 A 7

side.

-

+ 24 V

+ 12 V

S 1

S 2

S 3

S 4

S 6

S 7

S 8

S 9

S 10

S 11

S 12

S 13

S 14

S 16

NETZEINSPEISUNG

Standby-Spannung SOK

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

NETZSPANNUNG

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

P-230 V

P-230 V

A 1

A 2

A 3

A 4 S

A 4 Ö

L1 - 230 V

A 6

A 7

A 8

A 9

A 10

A 11 S

A 11 Ö

A 12 Ö

A 12 S

A 12 W

L1 - 230 V

A 13 Ö

A 13 S

A 13 W

L1 - 230 V

IO66_A1S

IO66_A2S

IO66_A3S

IO66_A4S

NETZ

NETZ

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K32

K32

K32

K32

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

A 12 PWM

A 13 PWM

A 14 PWM

A 16 PWM

OUT_A 7

OUT_A 8

OUT_A 9

OUT_A 10

IN1 = S 1

IN2 = S 2

IN3 = S 3

IN4 = S 4

IN6 = S 6

DL (Datenltg.)

DL 1

DL 2

CAN-H

CAN-L

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

N

IO66_A6Ö

IO66_A6S

IO66_A6W

� NETZ

� NETZ

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K32

K32

K32

K32

K1

K1

K1

K1

K1

K32

K32

K32

K32

K32

K32

K32

K32

K32

K32

K32

K1

K2

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

L1 - 230 V (Phase TWK)

PE

PE

PE

PE

PE

PE

PE

PE

PE

PE

PE

PE

PE

PE

PE

PE

PE

PE

PE

PE

PE

PE

PE

PE

PE

PE

IO66_A7Ö

IO66_A7S

IO66_A7W

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

� NETZ

� NETZ

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K1

K32

K32

K32

K1

K1

K1

K1

K1

K32

K32

K32

K32

K32

K32

K32

K32

K32

K32

K32

K1

K1

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

�

TU_Central controller 16x2-2021-06-wi - Errors and omissions excepted. All informaon, pictures and drawings are subject to change.

Compliance with the generally applicable and recognised rules of technology must be observed at all mes!

CAUTION: Installaon and wiring may only be carried out by authorised specialists.

18

18.07.2018

L. Böheim

M

M

T

S16

000

∑

m

³

shut off

shut off

with security flap

engine valve

Spouting device

with emptying

F

3-way-mixer

with locking valve

safety valve

pressure indicator

pump in the

direction of flow

setback flap

plate heat exchanger

flow rate

adjustment valve

flow switch

thermometer

heat meters

Sensor

conservator

drainage

S

3-way-mixer

with servomotor

name date NOTE: This pattern is just a

recommendation and

raise no requirement

on completeness,

in any regard!

pojectname:

rZR 16x2

Standard 2 Heizkreise, solar inspecting

draftsman

schematic-no.: changed

changed

S 1

S 2

S 3

S 11

110 3 2 8 96

47 5

T T

M

S 13

A 8/9

A 3

F

A 6

OSKAR°

S4

TT

F

S 6

KW

S 7

S 15

A 16 / PWM

A 1

WW

S 8

S 5

rZR 16x2

IO II

IO II

A 13

0- 10V

Auto- O - Hand

I

O

230V

Hand- O - Auto

Netz

T

M

TT

S 14

A 4

A 10/11

A 7

TT

S12

S 9

T T

S16

000

∑

m

³

S 10

solar thermal

A 2 / 230V

A 14 / PWM

A 2 / 230V

A 15 / PWM

heat generator 2

heat generator 1

external sensor

low temperature

heat circuit

drinking water

station

high temperature

heat circuit

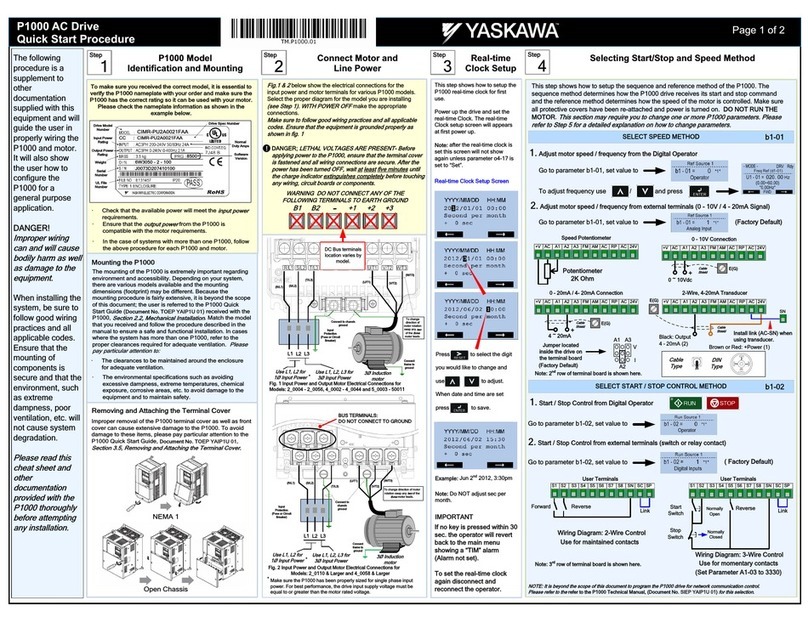

Standard programming

Functions with a yellow background are programmed, but

require the additional module IO66 (RSM) for activation.

19

TU_Central controller16x2-2021-06-wi - Errors and omissions excepted. All informaon, pictures and drawings are subject to change.

Compliance with the generally applicable and recognised rules of technology must be observed at all mes!

CAUTION: Installaon and wiring may only be carried out by authorised specialists.

Inputs (node 1) for standard hydraulics V4/04

Sensor input: Board terminal:

S1 K1 S1 GND

S2 K1 S2 GND

S3 K1 S3 GND

S4 K1 S4 GND Outdoor sensor in surface-mounted housing

GND

S6 K1 S6 GND Ultra-fast hot water outlet sensor

S7 K1 S7 GND

S8 K1 S8 GND

S9 K1 S9 GND

S10 K1 S10 GND Einschub sensor collector/solar thermal system

S11 K1 S11 GND

S12 K1 S12 GND unused in the standard

S13 K1 S13 GND

S14 K1 S14 GND

GND

Wire colours of the S15 : White = 24V / Green= S15 / Brown=GND

S16 K1 S16 GND unused in the standard

Sensor input: Board terminal:

S1 IN1 GND

S2 IN2 GND

S3 IN3 GND

S4 IN4 GND unused in the standard

GND unused in the standard

S6 IN6 GND

TU_Central controller 16x2-2021-06-wi - Errors and omissions excepted. All informaon, pictures and drawings are subject to change.

Compliance with the generally applicable and recognised rules of technology must be observed at all mes!

CAUTION: Installaon and wiring may only be carried out by authorised specialists.

20

Outputs (node 1) for standard hydraulics V4/04

Output: Board terminal:

A1 K1 A1 N/PE

A2 IK1 A2 N/PE

A3 IK1 A3 N/PE

A4 IK1 A4 N/PE

I

A6 IK1 A6 N/PE Charge pump Heat generator 2

A7 IK1 A7 N/PE Charge pump Heat generator 1

A8 K1 A8 N/PE

A9 K1 A9 N/PE

A10 K1 A10 N/PE

A11 K1 A11 S N/PE

A13 A13 W A13 S Potenal, if L1 jumper on A13W !

A13 PWM A13PWM GND

A14 PWM A14PWM GND Charging pump solar top primary (glycol circuit)

GND

A16 PWM A16PWM GND

Outputs: Board terminal:

A1 IO66_A1S N/PE

A2 IO66_A2S N/PE

A3 IO66_A3S N/PE unused in the standard

A4 IO66_A4S N/PE unused in the standard

N/PE

A6 IO66_A6S N/PE

Table of contents