Contents

Introduction.................................................................................................................................................... 5

Introduction to the User Guide ....................................................................................................................................... 5

Where to Get Help .......................................................................................................................................................... 5

Safety / Sécurité ............................................................................................................................................. 5

General Safety Considerations ........................................................................................................................................ 6

Specific Safety Considerations......................................................................................................................................... 6

Safety Symbol Index ........................................................................................................................................................ 7

Dymax Light-Curing System Safety Considerations ......................................................................................................... 7

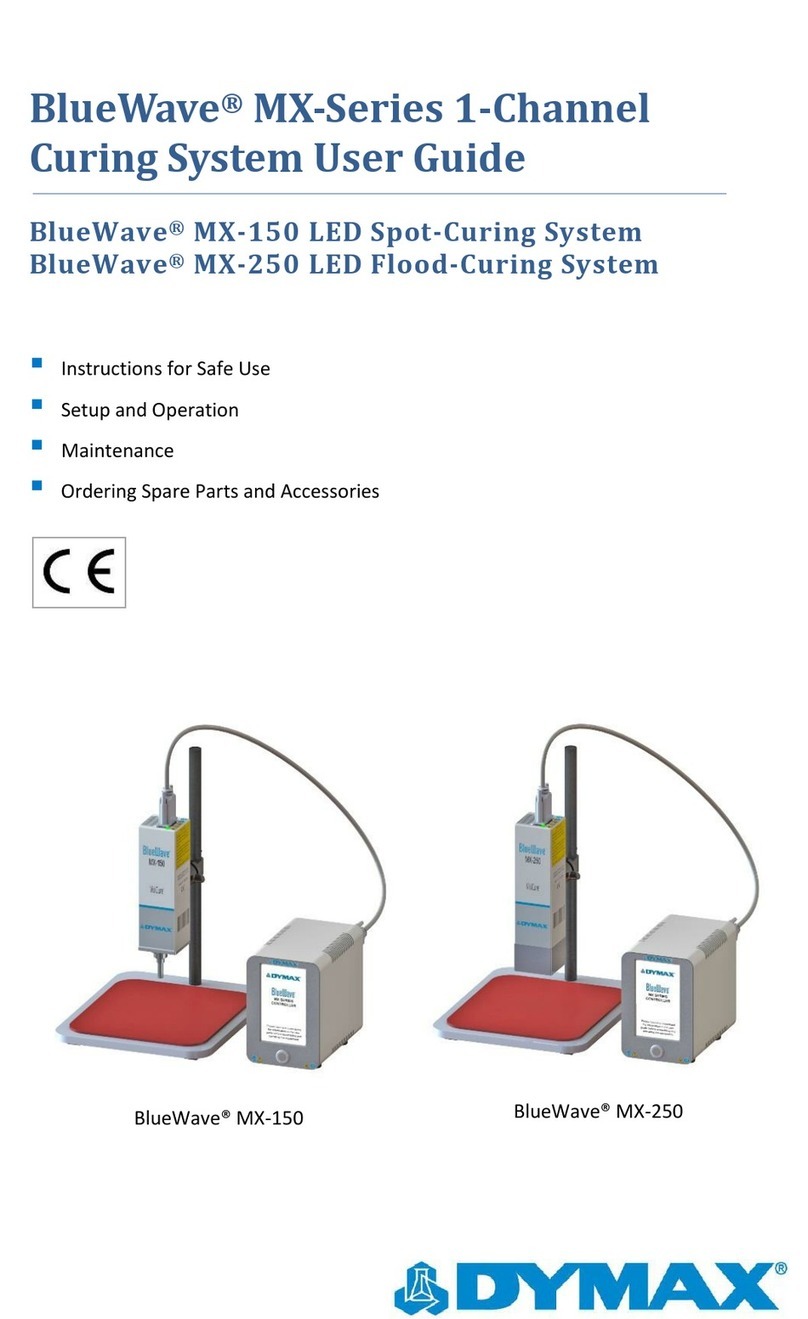

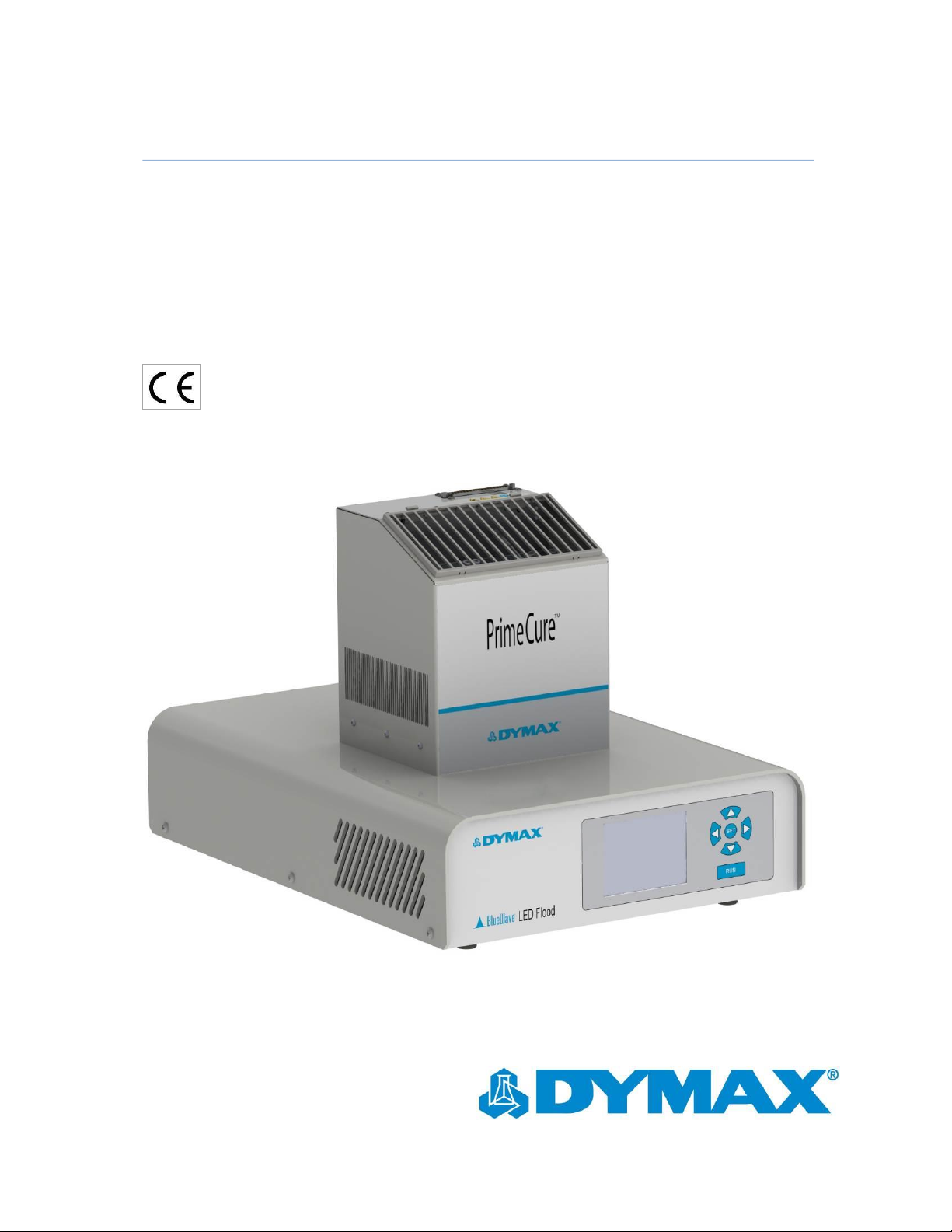

Product Overview ........................................................................................................................................... 9

Description of the BlueWave LED Flood System .............................................................................................................. 9

Special Features and Benefits of the BlueWave LED Flood System ............................................................................... 10

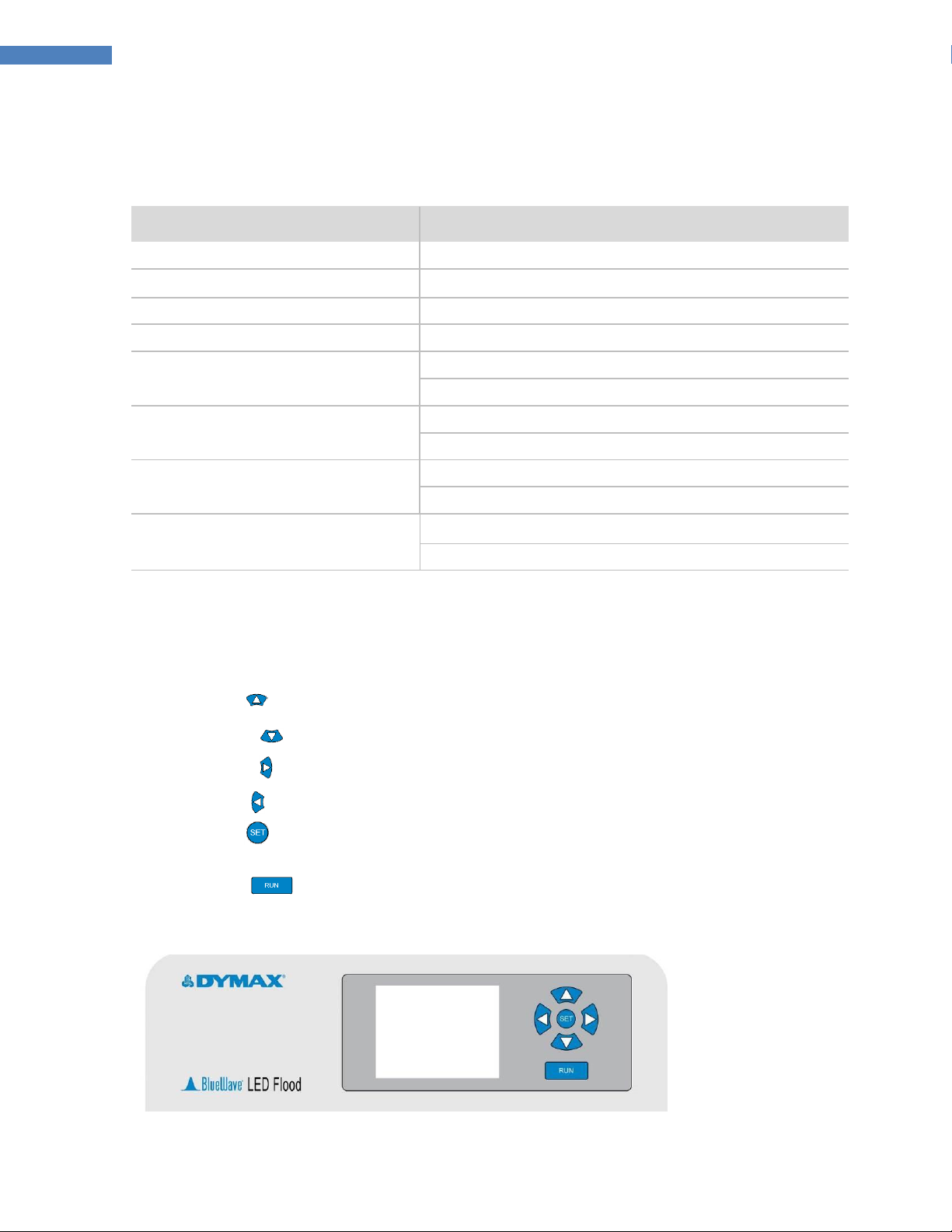

Front Control Panel ....................................................................................................................................................... 10

Back Panel ..................................................................................................................................................................... 11

Intensity Control Feature .............................................................................................................................................. 11

Operation Modes .......................................................................................................................................................... 12

Validation ...................................................................................................................................................................... 12

Assembly and Setup...................................................................................................................................... 12

Safety / Sécurité ............................................................................................................................................................ 12

Unpacking and Inspecting Your Shipment..................................................................................................................... 13

Parts Included in the BlueWave LED Flood System........................................................................................................ 13

System Connections...................................................................................................................................... 14

Interconnect Cable ........................................................................................................................................................ 14

Operating the LED Light ................................................................................................................................ 14

Adjusting Intensity......................................................................................................................................................... 14

Operating Modes........................................................................................................................................................... 15

Choosing an Operating Mode........................................................................................................................................ 16

Operating in Manual Mode........................................................................................................................... 19

Manual Mode Description............................................................................................................................................. 19

Procedure ...................................................................................................................................................................... 19

Operating in Timer Mode.............................................................................................................................. 19

Timer Mode Description................................................................................................................................................ 19

Adjusting the Timer ....................................................................................................................................................... 19

Operating in PLC Mode ................................................................................................................................. 20

PLC Mode Description ................................................................................................................................................... 20

Wiring the PLC Interface................................................................................................................................................ 21

Output Signal Definition ................................................................................................................................................ 23

Troubleshooting the PLC Interface ................................................................................................................................ 24

Testing Fixtures in PLC Mode ........................................................................................................................................ 24

Cleaning and Maintenance ........................................................................................................................... 24

Inspect and Replace Fuses............................................................................................................................................. 24