Contents

Introduction ...............................................................................................................5

Introduction to the User Guide .............................................................................. 5

Where to Get Help ................................................................................................. 5

Safety.........................................................................................................................6

General Safety Considerations............................................................................... 6

Safety Symbol Index............................................................................................... 6

Specific Safety Considerations ............................................................................... 7

Dymax UV Light-Curing System Safety Considerations .......................................... 9

Product Overview.....................................................................................................11

Description of BlueWave MX-Series 1CH Systems ............................................... 11

Features & Benefits.............................................................................................. 14

Controller Front Panel.......................................................................................... 15

Controller Back Panel........................................................................................... 16

Unpacking ................................................................................................................17

Parts Included ...................................................................................................... 17

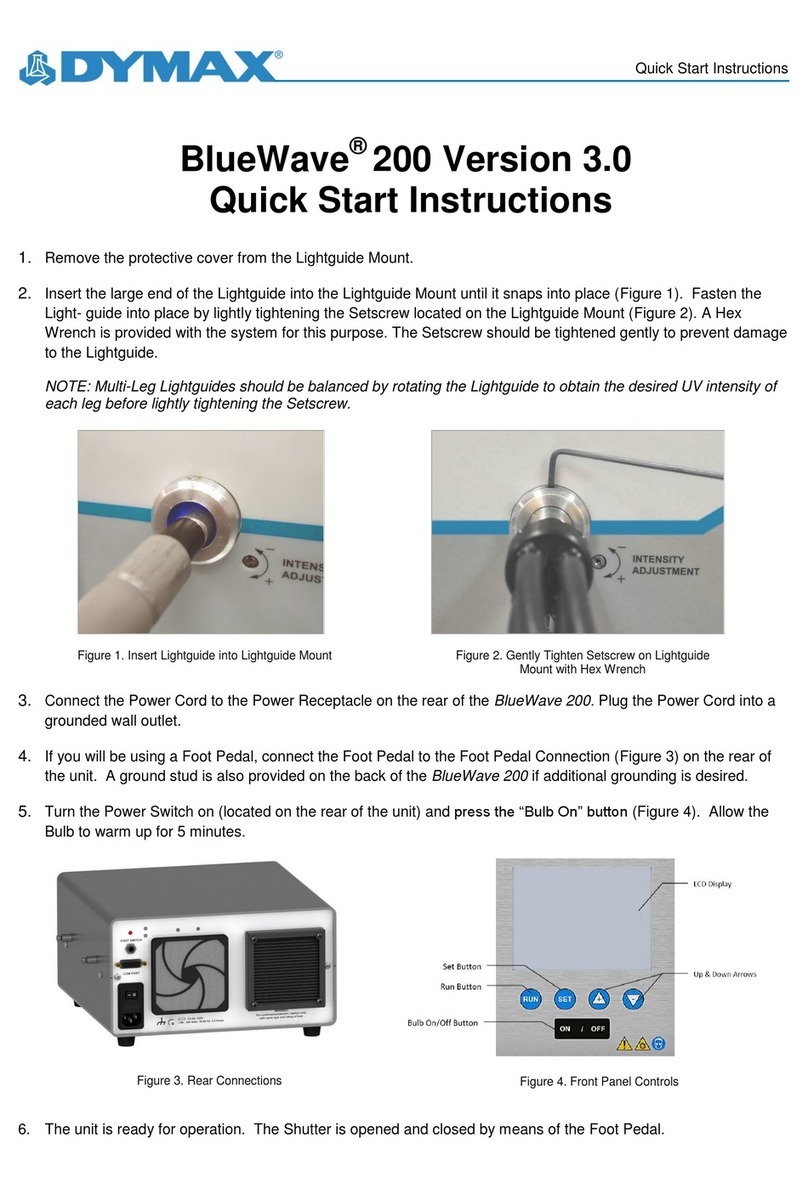

System Setup ........................................................................................................... 17

System Connections............................................................................................. 17

Modes of Operation ................................................................................................. 19

Manual Mode....................................................................................................... 19

Timer Mode.......................................................................................................... 19

PLC (Programmable Logic Controller) Operation ................................................. 20

Examples of PLC Wiring ............................................................................................ 23

Operation.................................................................................................................24

Control Screen...................................................................................................... 25

Irradiation ............................................................................................................ 27

Saving Programs................................................................................................... 28

System Settings ........................................................................................................28

Language Settings ................................................................................................ 29

Volume Settings ................................................................................................... 29

Brightness Settings............................................................................................... 30

User Settings/Boot Modes ................................................................................... 30