Read all safety warnings and all instructions. Failure to follow the warnings and instructions may result in electric shock, re and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS FOR FUTURE REFERENCE

The term “equipment” in the warnings refers to your (corded) vacuum system. Do not modify

Dynabrade products, they must be used as intended. Modifying equipment may create hazardous situations.

GENERAL POWER EQUIPMENT SAFETY WARNINGS

ASSEMBLY AND INSTALL

WARNING

CAUTION

• Visually inspect plugs and cords for frays, visible damage, and signs of deterioration or deformation.

• Plug equipment into proper outlet based on model/voltage. Always use a grounded power supply.

• Ensure that a clean dry drum is being used in conjunction with DrumVac kit.

• When unloading equipment from box, all other operators are to remain clear of work-cell.

• Use proper/safe methods when transporting equipment. Improper pushing and pulling methods will increase operator strain.

• When transporting equipment from work-cell to work-cell, do not pull in operator direction.

• Slowly remove vacuum head from packaging and stage on at surface before assembly.

• Slowly remove interface ring from packaging and install on top of 55 (208 Liters) Gallon Drum.

• With power source disconnected from system, apply the vacuum head to the top of the interface ring and lock in place.

• Be sure to properly lock down vacuum head to interface ring with provided latches on each side.

• Be sure to keep ngers and hands clear from pinch points upon re-assembly.

• Ensure to install DrumVac kit together with proper 55 (208 Liters) Gallon 33” High x 22 1/2” Dia Cylindrical ASTM grade 1.1mm wall thickness, Carbon Steel Open

Head Drum. UN-Solid Rating: 1A2/X400/S

Read and understand this tool manual before operating your tool. Follow all safety rules for the protection of operating personnel as well as

adjacent areas. For safety information, refer to Code of Federal Regulation –CFR 29 Part 1910, NFPA 79, NFPA 70, NFPA 652, IEC, ISO 12100, ISO

14121-2 TR, EN 50281, EN 50495, EN 14986, EN 15188, EN 16009 –Safety Requirements and applicable State and Local Regulations.

Some dust created by sanding, grinding, drilling, and other construction activities contain chemicals known to cause cancer, birth defects or other

reproductive harm. Some examples of these chemicals are:

• Lead from lead-based paints

• Crystalline silica from bricks and cement and other masonry products

• Arsenic and chromium from chemically treated lumber

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these chemicals:

work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to lter out

microscopic particles.

• Do not use for explosive metallic dust (Aluminum, Magnesium, etc.)

• Never use to exhaust chemical vapors.

• Not to be used for the collection of hot embers / dust particles.

The intended use of portable complete vacuum head assembly kit to be used with 55 (208 Liters) Gallon drums for the safe collecting of dust/chips

captured through the process of sanding with hand tools/General purpose of non-metallic materials such as wood, berglass, composites, and solid

surface etc.

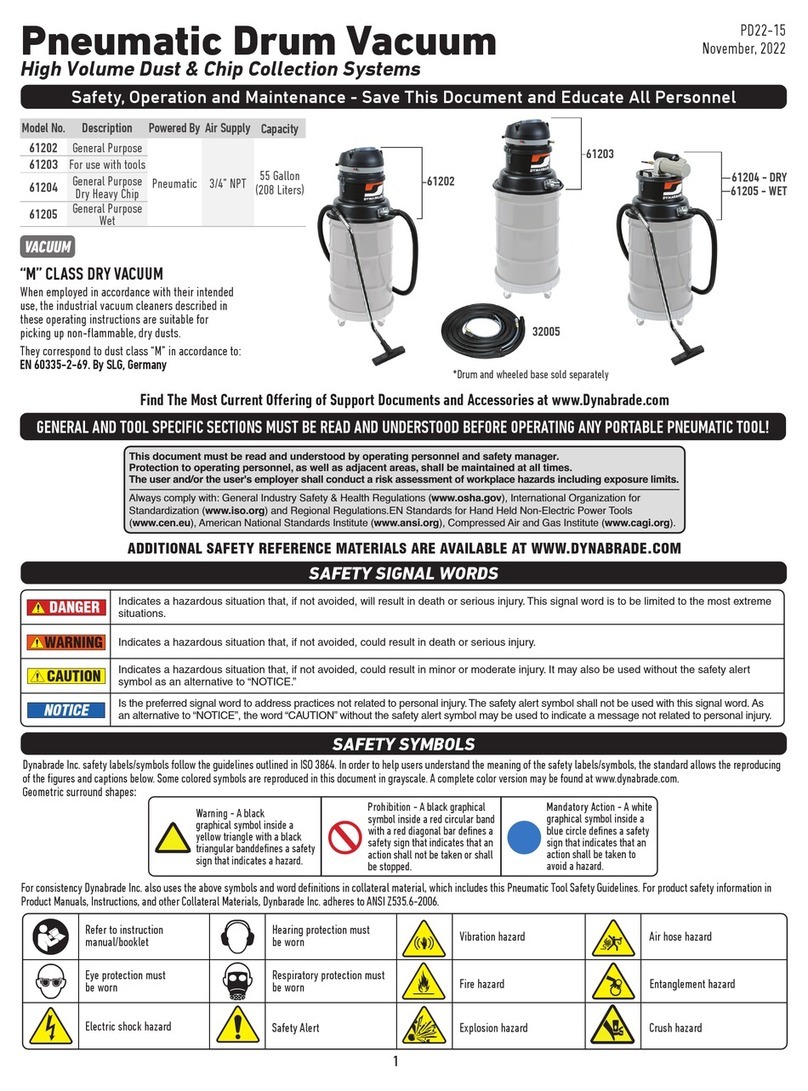

WARNING

Read and understand tool manual before work starts

to reduce risk of injury to operator, visitors, and tool.

Ear protection to be worn when exposure to sound,

exceeds the limits of applicable Federal, State or

local statues, ordinances and/or regulations.

Respiratory protection to be used when exposed to

contaminants that exceed the applicable threshold

limit values required by law.

Eye protection must be worn at all times,

eye protection to conform to ANSI Z87.1.

Practice safety requirements. Work alert, have

proper attire, and do not operate tools under the

inuence of alcohol or drugs.

Electric shock hazard. Avoid bodily contact with

grounded objects, bodies of water. Do not damage

cord set.

3

Tool Intent:

This unit must be grounded. If the unit should malfunction or break down, grounding

provides a path of least resistance for electric current to reducethe risk of electric shock.

Where it is critical to avoid shocks or sparks caused by static electricity,

an electrically conductive and grounded air supply hose must be used.

Grounding by means of a ground wire between both ends of the air supply tubing passing through vacuum hose is recommended.

WARNING

GROUNDING INSTRUCTIONS