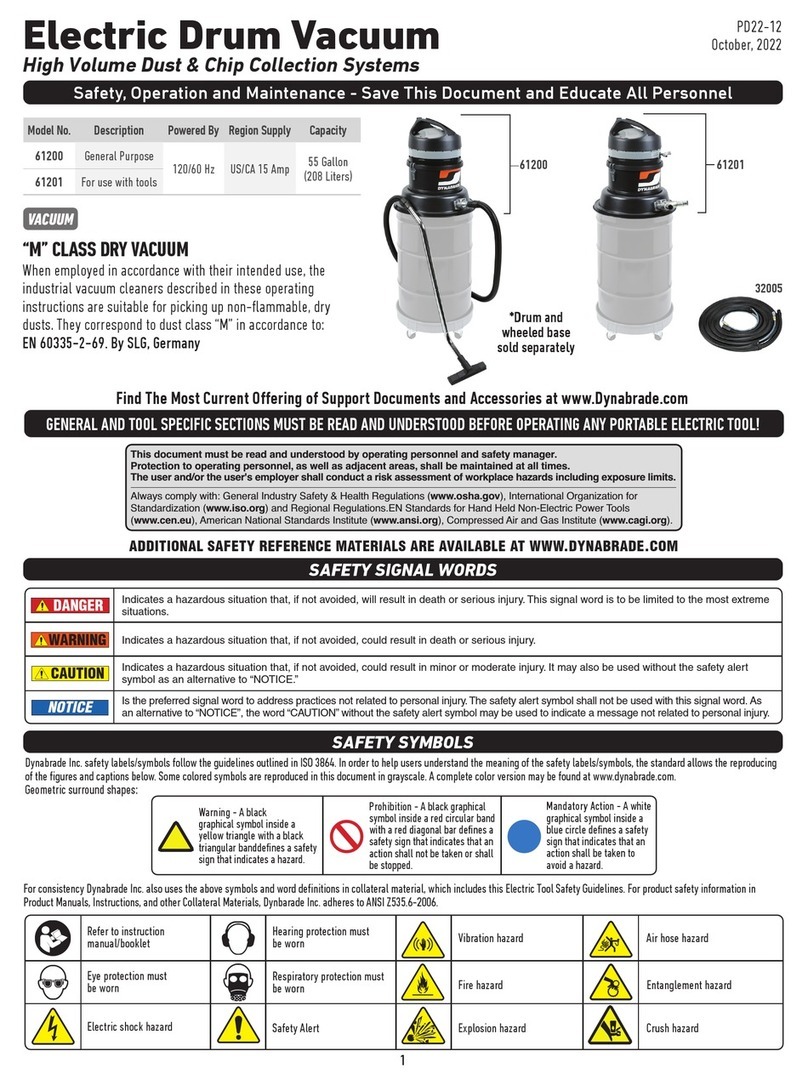

“M” CLASS DRY VACUUM

When employed in accordance with their intended

use, the industrial vacuum cleaners described in

these operating instructions are suitable for

picking up non-ammable, dry dusts.

They correspond to dust class “M” in accordance to:

EN 60335-2-69. By SLG, Germany

Pneumatic Drum Vacuum

High Volume Dust & Chip Collection Systems

Safety, Operation and Maintenance - Save This Document and Educate All Personnel

Find The Most Current Oering of Support Documents and Accessories at www.Dynabrade.com

PD22-15

November, 2022

*Drum and wheeled base sold separately

VACUUM

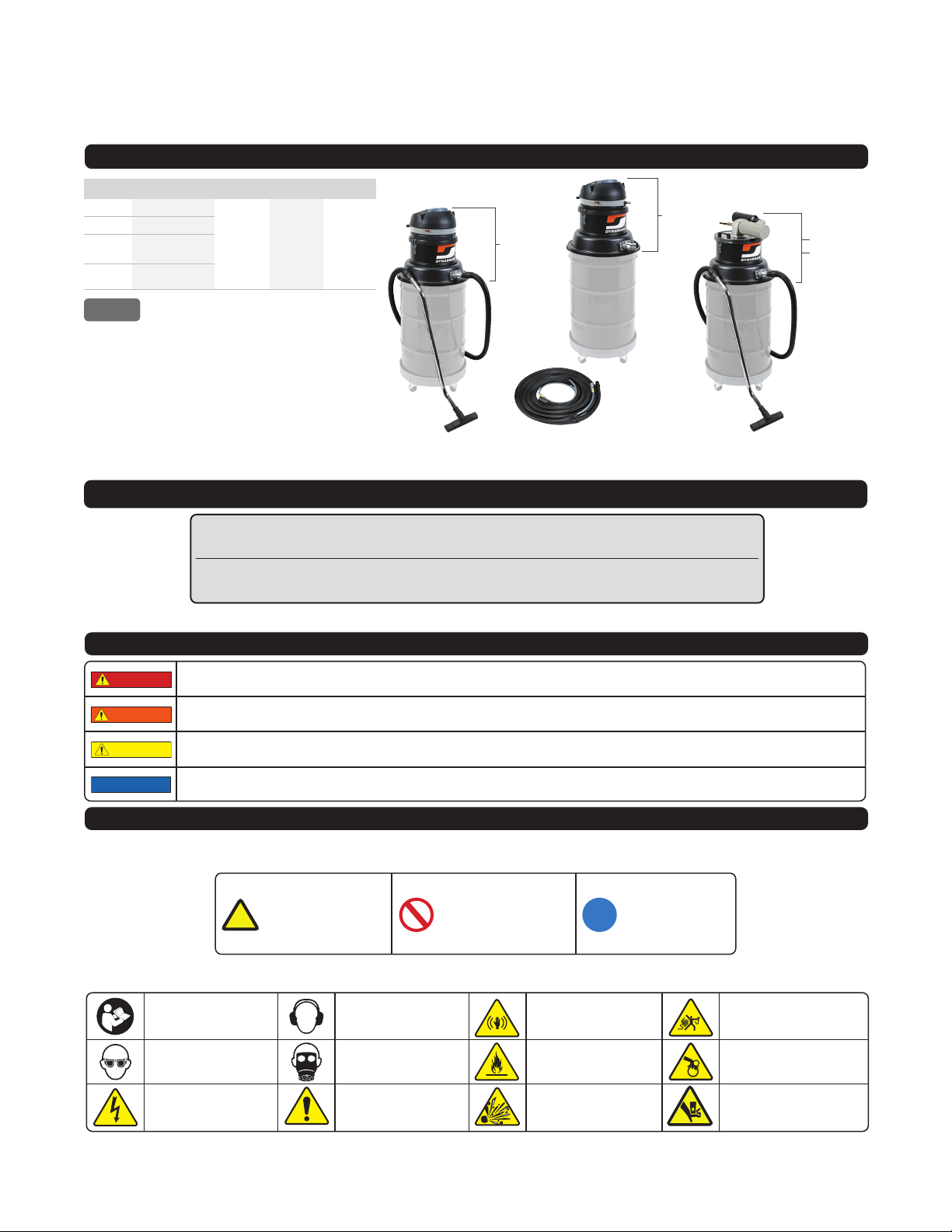

SAFETY SIGNAL WORDS

SAFETY SYMBOLS

ADDITIONAL SAFETY REFERENCE MATERIALS ARE AVAILABLE AT WWW.DYNABRADE.COM

Refer to instruction

manual/booklet

Hearing protection must

be worn

Eye protection must

be worn

Respiratory protection must

be worn

Electric shock hazard Safety Alert

Vibration hazard Air hose hazard

Fire hazard Entanglement hazard

Explosion hazard Crush hazard

Indicates a hazardous situation that, if not avoided, will result in death or serious injury.

This signal word is to be limited to the most extreme situations.

Indicates a hazardous situation that, if not avoided, could result in death or

serious injury.

Indicates a hazardous situation that, if not avoided, could result in minor or moderate

injury. It may also be used without the safety alert symbol as an alternative to

“NOTICE.”

Is the preferred signal word to address practices not related to personal injury. The safety alert symbol

shall not be used with this signal word. As an alternative to “NOTICE”, the word “CAUTION” without

the safety alert symbol may be used to indicate a message not related to personal injury.

DANGER

WARNING

CAUTION

NOTICE

Warning - A black

graphical symbol inside a

yellow triangle with a

black triangular band

defines a safety sign that

indicates a hazard.

Prohibition - A black

graphical symbol inside a

red circular band with a

red diagonal bar defines a

safety sign that indicates

that an action shall not be

taken or shall be stopped.

Mandatory Action- A

white graphical symbol

inside a blue circle defines

a safety sign that

indicates that an action

shall be taken to avoid a

hazard.

Dynabrade Inc. safety labels/symbols follow the guidelines outlined in ISO 3864. In order to help users understand the

meaning of the safety labels/symbols, the standard allows the reproducing of the figures and captions below. Some colored

symbols are reproduced in this document in grayscale. A complete color version may be found at www.dynabrade.com.

Geometric surround shapes:

This document must be read and understood by operating personnel and safety manager.

Protection to operating personnel, as well as adjacent areas, shall be maintained at all times.

The user and/or the user's employer shall conduct a risk assessment of workplace hazards including exposure limits.

Always comply with: General Industry Safety & Health Regulations (www.osha.gov), International Organization for

Standardization (www.iso.org) and Regional Regulations.EN Standards for Hand Held Non-Electric Power Tools

(www.cen.eu), American National Standards Institute (www.ansi.org), Compressed Air and Gas Institute (www.cagi.org).

GENERAL AND TOOL SPECIFIC SECTIONS MUST BE READ AND UNDERSTOOD BEFORE OPERATING ANY PORTABLE PNEUMATIC TOOL!

For consistency Dynabrade Inc. also uses the above symbols and word denitions in collateral material, which includes this Pneumatic Tool Safety Guidelines. For product safety information in

Product Manuals, Instructions, and other Collateral Materials, Dynbarade Inc. adheres to ANSI Z535.6-2006.

Dynabrade Inc. safety labels/symbols follow the guidelines outlined in ISO 3864. In order to help users understand the meaning of the safety labels/symbols, the standard allows the reproducing

of the gures and captions below. Some colored symbols are reproduced in this document in grayscale. A complete color version may be found at www.dynabrade.com.

Geometric surround shapes:

SAFETY SIGNAL WORDS

SAFETY SYMBOLS

Refer to instruction

manual/booklet

Eye protection must

be worn

Electric shock hazard

Hearing protection must

be worn

Respiratory protection must

be worn

Safety Alert

Vibration hazard

Fire hazard

Explosion hazard

Air hose hazard

Entanglement hazard

Crush hazard

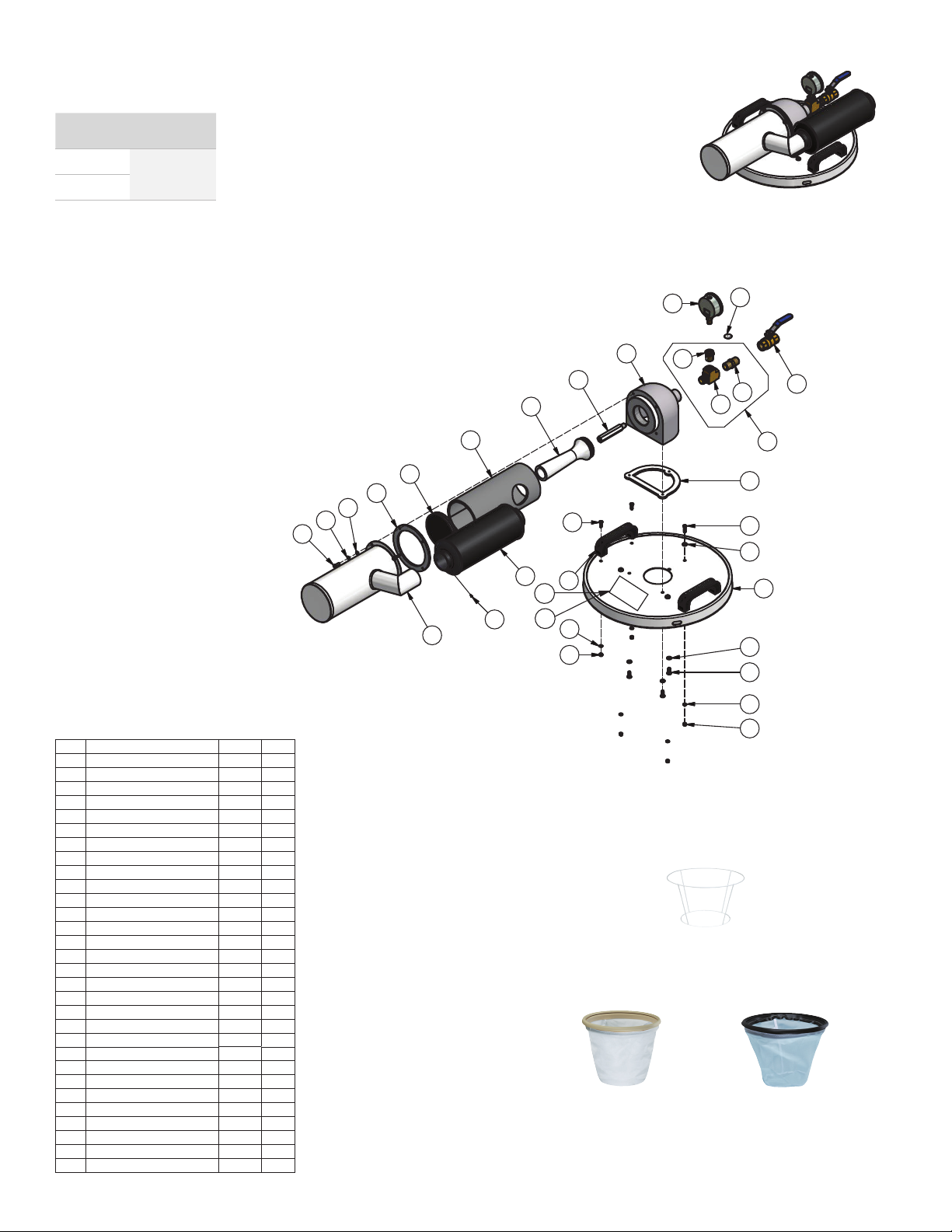

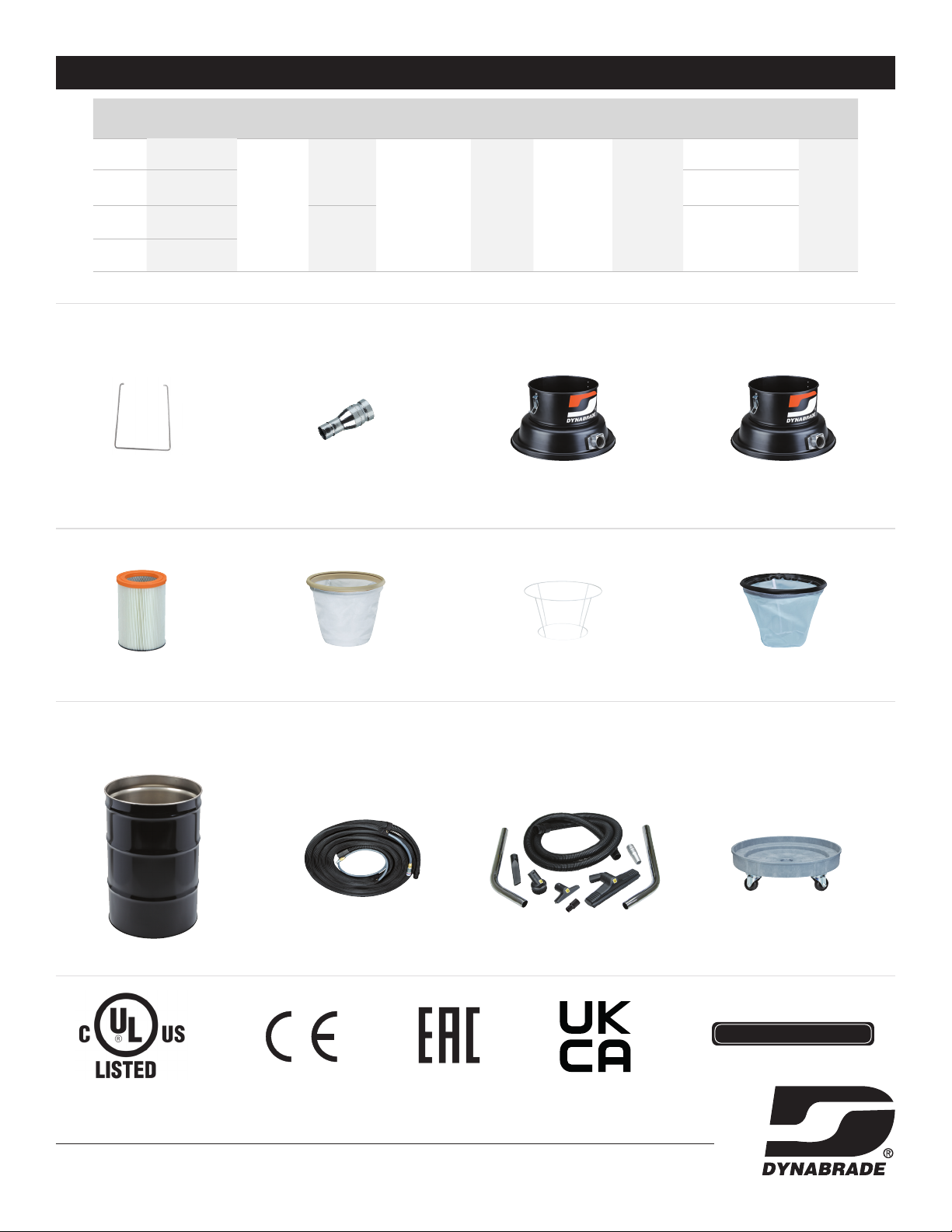

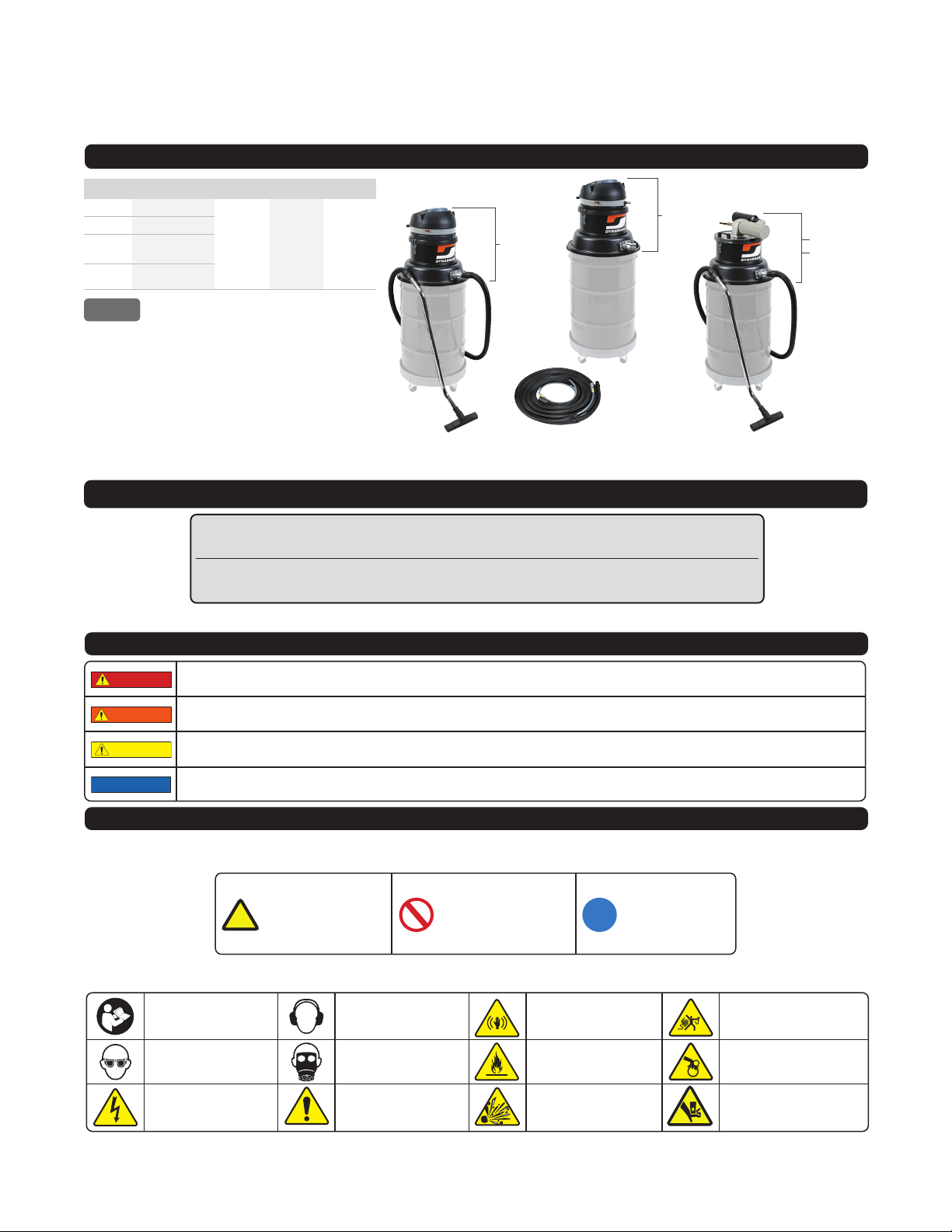

Model No. Description Powered By Air Supply Capacity

61202 General Purpose

Pneumatic 3/4” NPT 55 Gallon

(208 Liters)

61203 For use with tools

61204 General Purpose

Dry Heavy Chip

61205 General Purpose

Wet

61202 61204 - DRY

61205 - WET

Warning - A black

graphical symbol inside a

yellow triangle with a black

triangular banddenes a safety

sign that indicates a hazard.

Prohibition - A black graphical

symbol inside a red circular band

with a red diagonal bar denes a

safety sign that indicates that an

action shall not be taken or shall

be stopped.

Mandatory Action - A white

graphical symbol inside a

blue circle denes a safety

sign that indicates that an

action shall be taken to

avoid a hazard.

DANGER

WARNING

CAUTION

NOTICE

DANGER

WARNING

CAUTION

NOTICE

DANGER

WARNING

CAUTION

NOTICE

Indicates a hazardous situation that, if not avoided, will result in death or serious injury. This signal word is to be limited to the most extreme

situations.

Indicates a hazardous situation that, if not avoided, could result in death or serious injury.

Indicates a hazardous situation that, if not avoided, could result in minor or moderate injury. It may also be used without the safety alert

symbol as an alternative to “NOTICE.”

Is the preferred signal word to address practices not related to personal injury. The safety alert symbol shall not be used with this signal word. As

an alternative to “NOTICE”, the word “CAUTION” without the safety alert symbol may be used to indicate a message not related to personal injury.

DANGER

WARNING

CAUTION

NOTICE

1

61203

32005