2

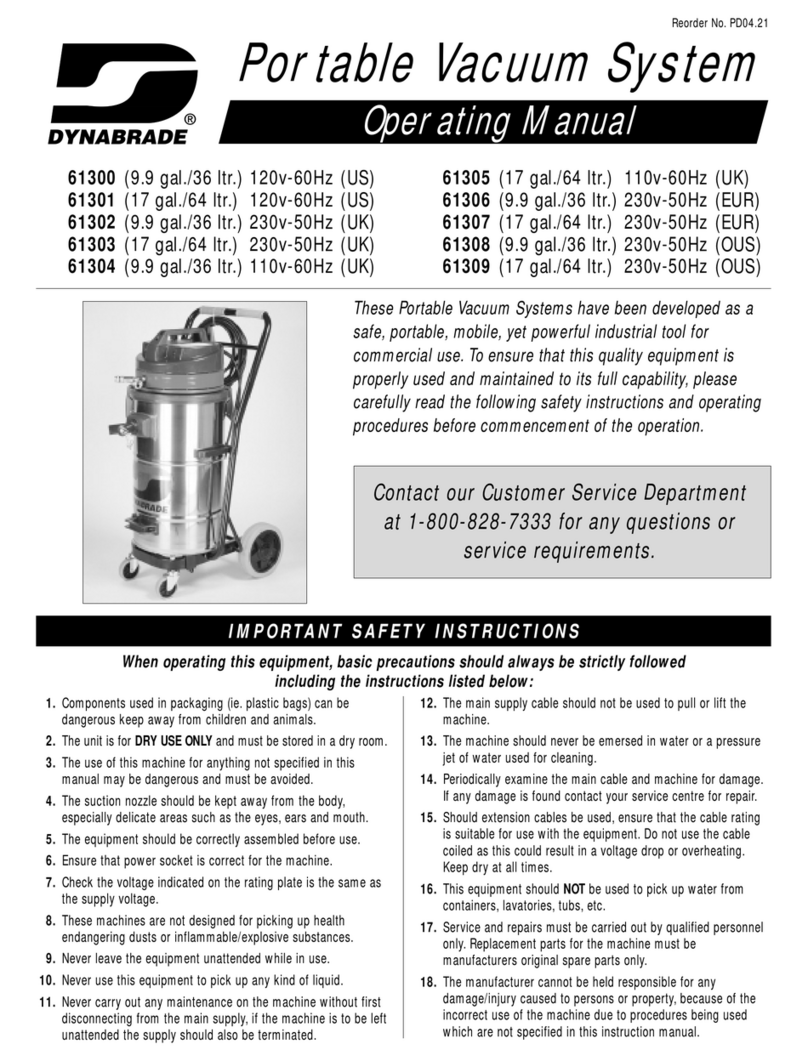

ASSEMBLY INSTRUCTIONS

1. While opening the carton, carefully inspect outside of the carton for

any sign of transportation damage, and if so, notify your shipper

immediately.

2. Remove motorhead and HEPA filter assembly from the first box and

tank/dolly assembly from the second box. Remove accessories from

vacuum tank.

3. Install disposable vacuum bag (included) inside bag restrainer and

connect to the manifold near the bottom of the canister of the

vacuum. The bag restrainer keeps the bag from over expanding.

4. Install the HEPA filter assembly with a pre-filter onto the tank.

5. Return Motorhead Assembly to the unit making sure the protruding

fitting mates with the recess on the HEPA filter and lock the four rim

latches to secure Motorhead/Vacuum Head Assembly in position.

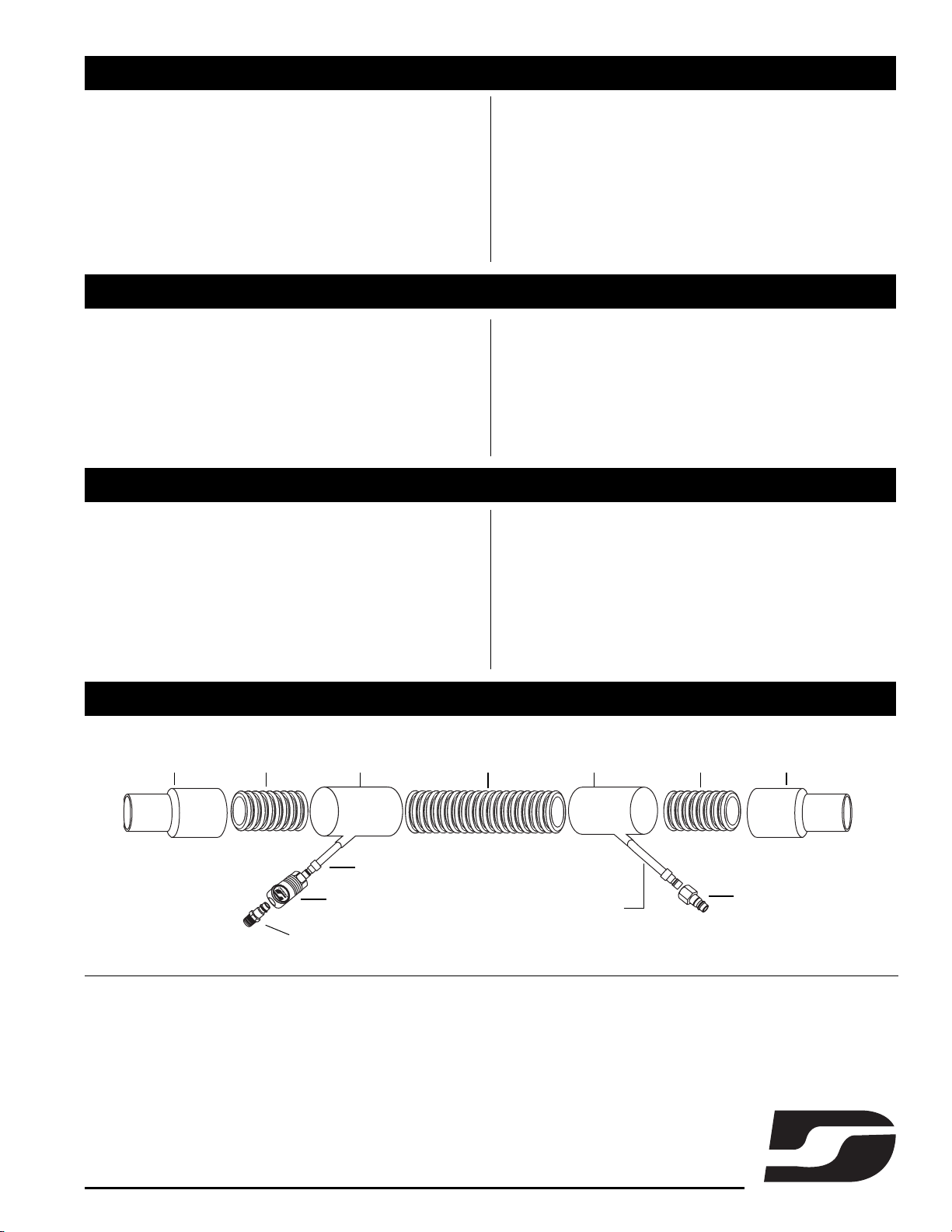

6. On the vacuum hose assembly, note that the air line (the smaller of

the two) protrudes at both ends and is longer than the vacuum hose.

7. Install both quick coupler (P/N 98271) male ends to air outlets

located on vacuum head assembly.

8. Insert vacuum hoses.

9. Install air supply inlet fitting (1/2" NPT female threads - P/N 98271)

to the back side of Motorhead Assembly. Connect air supply, air

pressure should be adjusted according to the pressure requirement

of the air tools you are using. Do not exceed 110 PSIG (7.6 Bar).

Some pressure drop is unavoidable between the main air supply and

the air tools due to internal flow resistance in a long air hose.

1/2" INTERNAL DIAMETER SUPPLY AIR LINE is recommended.

Set regulator by installing an in-line pressure gage (Part No.

94315) at the inlet of the air tool being used. Run the tool and

adjust regulator such that there is 90 PSIG/6.2 Bar @ the

tool inlet.

The installation of a Dynabrade Filter-Regulator-Lubricator (FRL

Part No. 10681) is highly recommended to protect the unit and

the air tools.

Where it is critical to avoid shocks or sparks caused by static

electricity, an air supply hose which is electrically conductive

must be used.

10. Plug unit in and green light will light.

11. Flip switch to “ON” for normal control of unit; flip to “AUTO” to

control vacuum with air tool use.

12. Connect your Dynabrade air tool or accessory and you are now

ready for working with the Dynabrade Portable Vacuum System.

Refer to the drawing and parts list for the name and location of parts.

IMPORTANT SAFETY INSTRUCTIONS (CONT.)

After finishing work:

1. Switch off the vacuum and unplug the power cord.

2. Wind up the power cord.

3. Dispose of collection filter bag.

4. Clean the vacuum inside and outside by suction and wiping.

5. Store the vacuum indoors in clean, dry place.

* This appliance is provided with an automatically reset thermal limiter to avoid damage to the motor.

SAVE THESE INSTRUCTIONS

INSTRUCTIONS TO BE STRICTLY FOLLOWED

•Components used in packaging (i.e. plastic bags) can be dangerous: keep away from children and animals.

•ATTENTION: This machine cannot be utilized outdoor with rainy weather.

•The use of this machine for anything not specified in its manual may be dangerous and must be avoided.

•The suction nozzle should be kept away from the body, especially from delicate areas such as eyes, ears and mouth.

•The equipment should be correctly assembled before use.

•Ensure that power socket used is correct for the machine plug.

•Ensure that the voltage indicated on the rating plate is the same as the power supply voltage.

•WARNING: This machine is not designed for picking up health endangering dusts (i.e. fireplace ash) or inflammable/explosive substances.

•Never leave the equipment unattended while in use.

•Never use this equipment to pick up any kind of hazardous liquids.

•Always remove the plug from the socket before carrying out any operation with the machine or whenever the machine remains unattended or can be

handled by children or people not conscious.

•The power cord should not be used to pull or lift the machine.

•Never immerse the machine in water for cleaning nor use pressure water jets to wash it.

•Should the power cord be damaged, this must be either replaced by the manufacturer or by its service center or in case by a person having similar skills,

so as to prevent any risk.

•If you use extension cables make sure they are placed on dry surfaces and protected from eventual water jets.

•Service and repairs must be carried out by qualified personnel only. Replacement parts for the machine must be original spare parts only.

•The manufacturer cannot be held responsible for any damage/injury caused to persons or property, because of the incorrect use of the machine due to

procedures being used which are not specified in this manual.