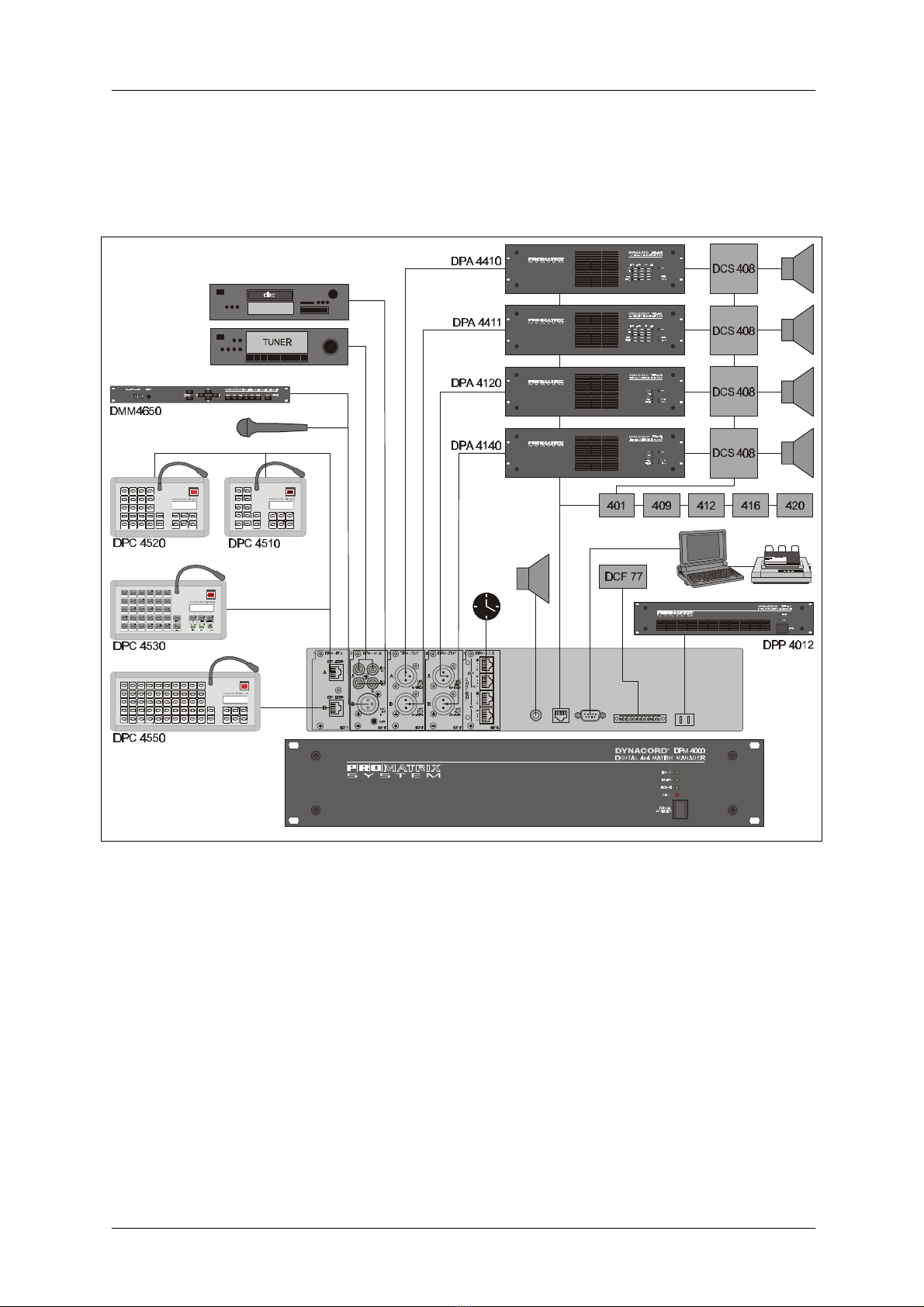

SYSTEM DESCRIPTION

PROMATRIX System User Handbook 1.1 3-3

3.5 Paging Stations

The DPC 4000 Series paging consoles are mainly meant for transmitting voice messages and calls but also to

manually control the PROMATRIX system. Available paging station functions are: line/group selection, voice

messages, program assignment, launching gong and alarm signals, and reproduction of voice message memory

announcements. Additionally, special commands include volume control, monitor selection, preset switching,

lighting control, function status indication, etc. Thus, it is possible to configure the paging consoles to serve as

operation panels for general control purposes.

If a voice call is being launched into a speaker line that is already busy with other audio transmissions, the caller

gets a busy-sign, i. e. the BUSY-LED blinks. In case the calling terminal has a higher priority it will interrupt any

messages from other paging stations or audio signals with lower priority levels. Interruption does not take place

uncontrolled anymore. Before actually interrupting a transmission, the blinking LED indicates that a line or group

is busy when selecting a destination, leaving the choice to the operator, whether he/she immediately wants to

interrupt or wait upon the conclusion of the momentary reproduced program.

3.6 Control Inputs And Outputs

By using the control inputs, it is possible to link the PROMATRIX system to fire alert systems, burglary alert

systems, or to a central operating desk. It is also possible to connect external switches, breakers, rotary controls

or rotary encoders, respectively to query control outputs of external units (power supplies, power amplifiers, …).

The control outputs allow switching external devices ON or OFF, trigger signals and events, switch monitor

sources, remote control doors, gates or shutters, generate analog signals for the control of multimedia systems,

etc.

A total of 130 control inputs for logic levels, 128 control inputs for analog levels, 16 inputs for rotary encoders, 127

logic-control outputs, and 128 analog-control outputs are usable.

3.7 Clock / Calendar

The PROMATRIX manager DPM 4000 has an integrated quartz-controlled real-time clock which can be set for

radio-controlled DCF 77 operation using the optional antenna (DCF 77 tuner NRS 90193). The system clock

automatically recognizes leap years and, if in DCF 77 mode, automatically switches between daylight saving time

and standard time.

The system clock provides the possibility to control up to 40 external slave clocks. For this purpose, the DPM

4000 employs a special, short-circuit-proof output for pole changing impulses. Slave clocks are automatically re-

synchronized whenever a time difference to the system clock is detected; like for instance in cases of power

outage or when time values were entered manually.

It is possible to activate pre-set functions like break-gong signals, background music, remotely controlled gates,

switch lights ON/OFF, etc. when using system clock and calendar function together All the functions mentioned

before can be programmed for specific days; but also hourly, daily, weekly, monthly, and yearly activation is

possible. Up to 500 time-controlled events can be programmed.

3.8 Monitoring

The PROMATRIX manager DPM 4000 embodies a monitor amplifier with headphones/speaker output. The

integrated logic-switching circuit provides the opportunity to listen to the signals of any internal input and output.

Assigning external sound sources to the monitor bus is possible as well. This additionally allows monitoring

amplifier outputs or pre-listen to the contents of external voice message memories and other audio devices.

The remote control’s wiring already includes all the cabling necessary for the pre-/post-listen feature when using

remote-controlled amplifiers.

When using the DCS 420 PROMATRIX MONITOR MANAGER, easy programming and operating is available.

See also chapter 5.4.7