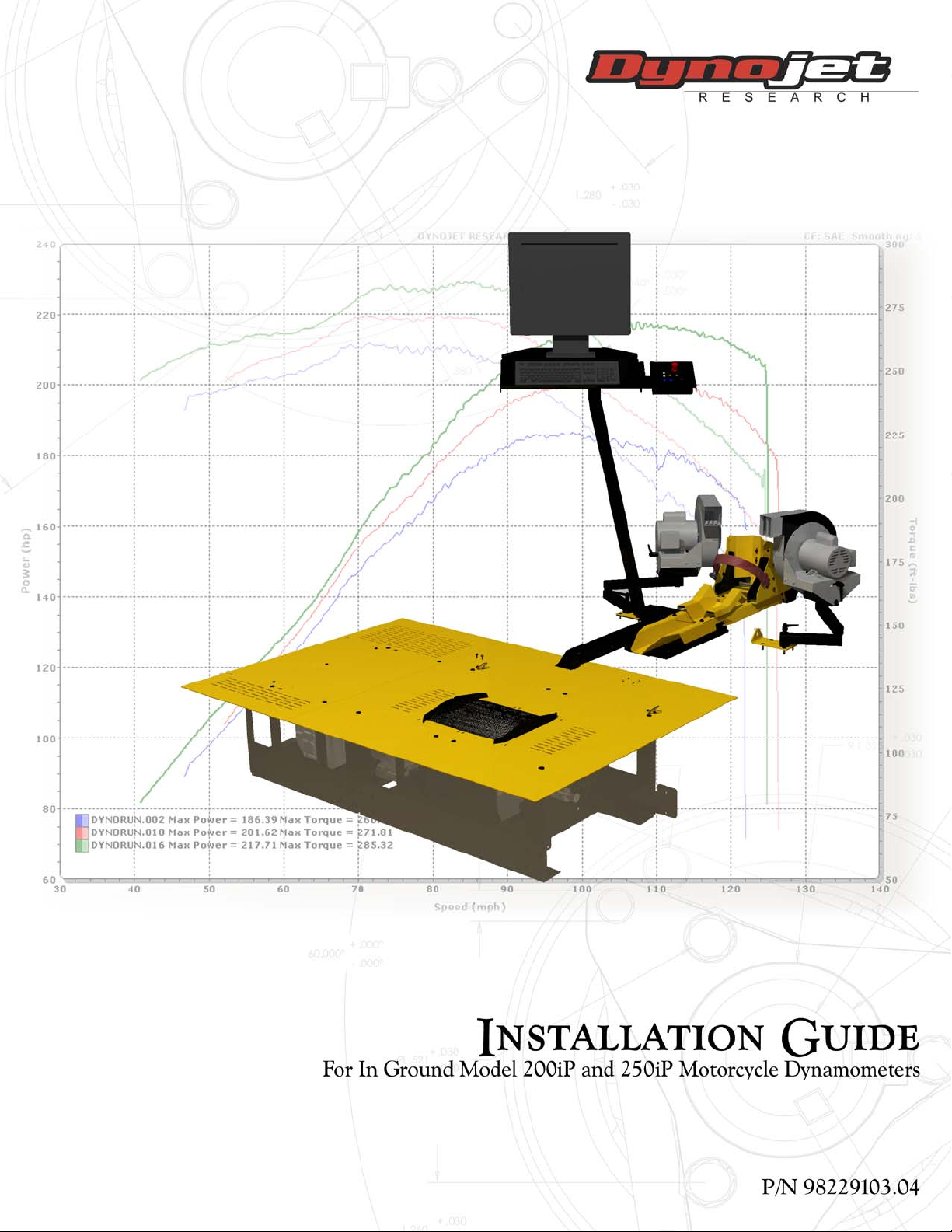

In Ground Model 200iP/250iP Motorcycle Dynamometer Installation Guide

TABLE OF CONTENTS

ii

Secure the Drum and Brake Module to the Pit Floor . . . . . . . . . . . . . . . .2-16

Pickup Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-17

Carriage Plate and Tire Carriage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Installing the Carriage Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-18

Installing the Tire Carriage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Blower and Monitor Support Installation . . . . . . . . . . . . . . . . . . . . . . . . . 2-21

Mark and Drill Blower Mounts and Support Arm Mounting Holes . . . . . . 2-22

Installing the Monitor Support and Junction Box . . . . . . . . . . . . . . . . . . . 2-23

Installing the Blower Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

Installing the Monitor Arms and Monitor Tray . . . . . . . . . . . . . . . . . . . . . 2-25

Cable Track Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

Routing Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

Battery Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

Installing the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-30

Accessing the CPI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

Routing the Control Panel and Pendant Cables . . . . . . . . . . . . . . . . . . . .2-32

Routing the High Pressure Blower Cables . . . . . . . . . . . . . . . . . . . . . . . . .2-36

Routing the Power Carriage and Wheel Clamp Cables . . . . . . . . . . . . . . .2-37

Routing the Eddy Current Brake, Battery, and Dyno Power Cables . . . . . . 2-38

Routing the Pickup Card and Dyno Electronics Cables . . . . . . . . . . . . . . .2-40

Routing the Air Pump Power, Air Fuel Sensor, and Dyno Electronics

Power Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-41

Wiring the Breakout Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-42

Power Carriage Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-44

Tire Stop Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-45

Final Adjustments and Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-46

Turning On the Dyno Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-46

High Pressure Blower Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-47

Power Carriage Final Adjustments and Tests . . . . . . . . . . . . . . . . . . . . . .2-47

Wheel Clamp Final Adjustments and Tests . . . . . . . . . . . . . . . . . . . . . . . . 2-47

Pit Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-48

Changing the Eddy Current Brake Cover for Right Side Installations . . . . .2-48

Installing the Pit Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-50

Junction Box Cover, Cable Cover, and End Cap . . . . . . . . . . . . . . . . . . .2-55

Zip Tube . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-56

Chapter 3 Accessories

Main Dyno Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Air Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Routing the Air Brake Cable and Air Hose . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Installing the Emergency Stop Sticker . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Air Brake Final Adjustments and Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Changing the Brake Pads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Adjusting the Brake Pad Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-15

Compressed Air Pump Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-16

Wheel Clamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

Installing the Wheel Clamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Wheel Clamp Final Adjustments and Tests . . . . . . . . . . . . . . . . . . . . . . . . 3-20