Service manual

Technical info.

06

DDM electrical fault diagnostics

No power to either motor (power LED off)

1. Check for damage/electrical failure to the plug and powercord.

2. Check the resistance across the fuse (UK only).

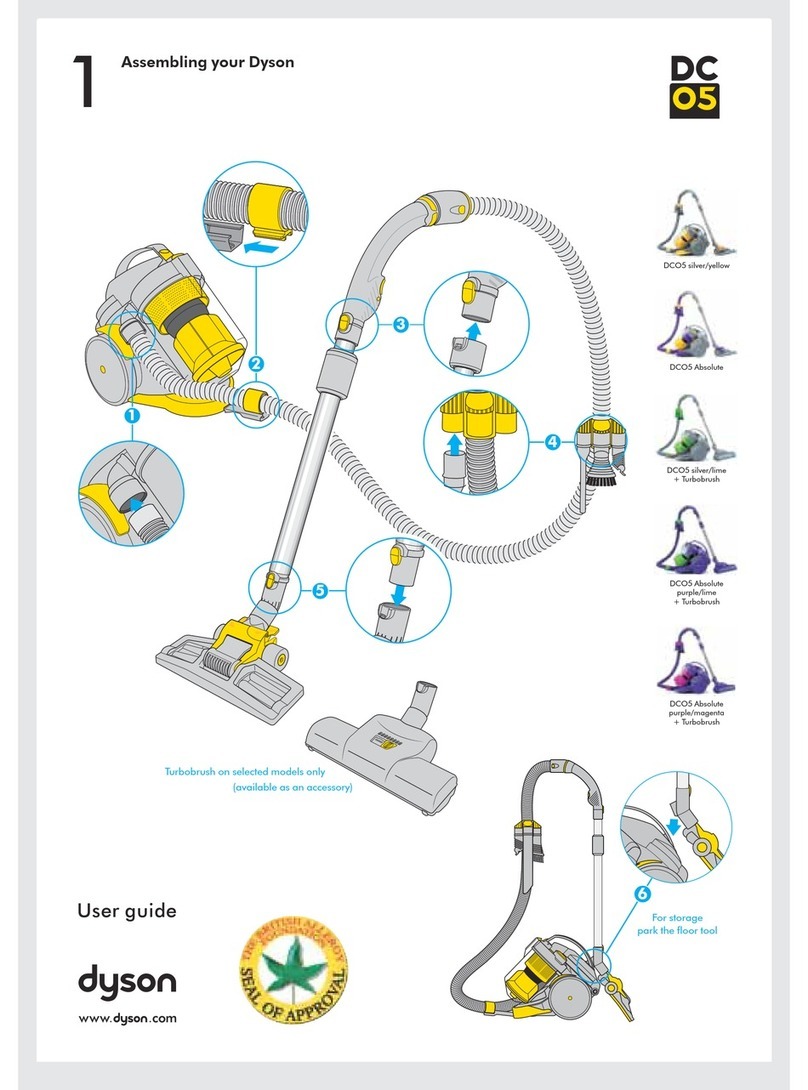

3. Check mechanical connection at points 1-8.

4. Check the resistance between the live pin on the plug and point 1.

5. Check the resistance between the neutral pin on the plug and point 2.

6. Check the resistance between points 1 and 8.

7. Check the resistance between points 2 and 7.

No power to either motor (power LED illuminated GREEN)

1. Replace the satellite assembly and retest.

2. If the vacuum motor is not working after replacing the satellite assembly see the ‘No power to

the vacuum motor (brushbar motor operates)’ section below.

3. If the brushbar motor is not working after replacing the satellite assembly see the ‘No power

to the brushbar motor (vacuum motor operates)’.

No power to the vacuum motor (brushbar motor operates)

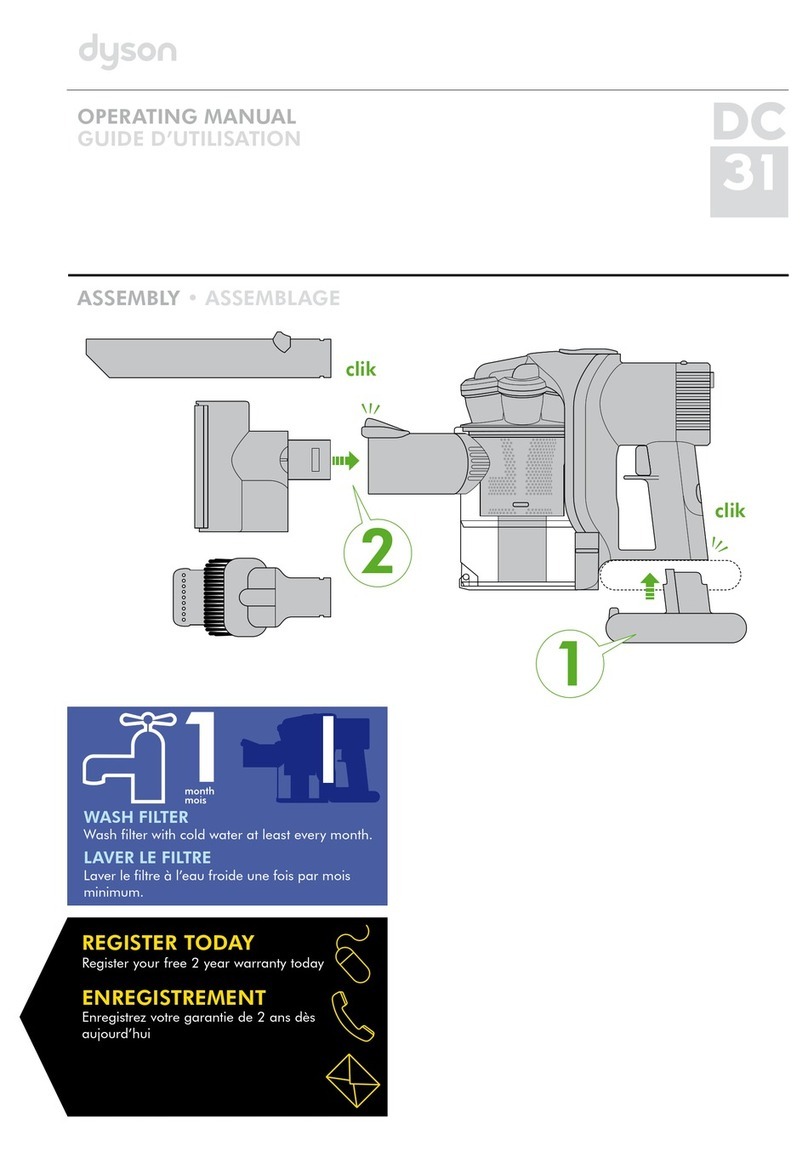

1. Ensure that the motor wires are attached to points J2 and J4 of the PCB assembly EMC.

2. Ensure all connections are correctly seated onto the satellite PCB.

3. Replace the satellite PCB.

4. Replace the DDM assembly.

No power to the brushbar motor (vacuum motor operates)

1. Check the resistance between points 9 and 12.

2. Check the resistance between points 10 and13.

3. Check the resistance between points 11 and 14.

4. Replace the Motorhead floor tool assembly and retest.

5. If after retesting the product the brushbar motor still does not work replace the satellite assembly.

Unable to turn on the product using the fingertip controls

1. Check the wand handle LED is illuminating when the buttons are pressed. If not, replace the

batteries.

2. If the LED is illuminating re-tune the wand handle to the machine (see page 8 for details).

3. Check that the Antenna is not damaged and is sufficiently attached to point SA1 of the satellite

assembly.

4. Replace the satellite assembly.

Brushbar operates in the stowed position or when lifted off the floor (Motorhead models only)

1. Replace the Motorhead floor tool assembly and retest.

2. If after retesting the product the brushbar still operates in the stowed position or when lifted off the

floor replace the satellite assembly.

Unable to turn on the product using the button on the main body

1. Replace the switch/PCB assembly.

2. Replace the satellite assembly.

3. Replace the DDM assembly.