E-Core RageTurf dBTile User manual

www.ecoreintl.com

Ecore RageTurf dBTile

Technical Manual

Installation · Maintenance · Warranty

Manufactured in the U.S.A.

Base Preparation

General Information 2

Tools / Material Required 2

Installation

Site Work & Base Options 3

Quad Blok Installation 5

Cutting Tiles & Accessories 6

Fully Adhered Installation 7

Maintenance

Maintenance 7

Warranty

Warranty 9

Revised 28Jun2023

Supersedes all previous versions.

Check website for updates.

www.ecoreintl.com 2

RageTurf dBTile Technical Manual

Installation

I. GENERAL INFORMATION

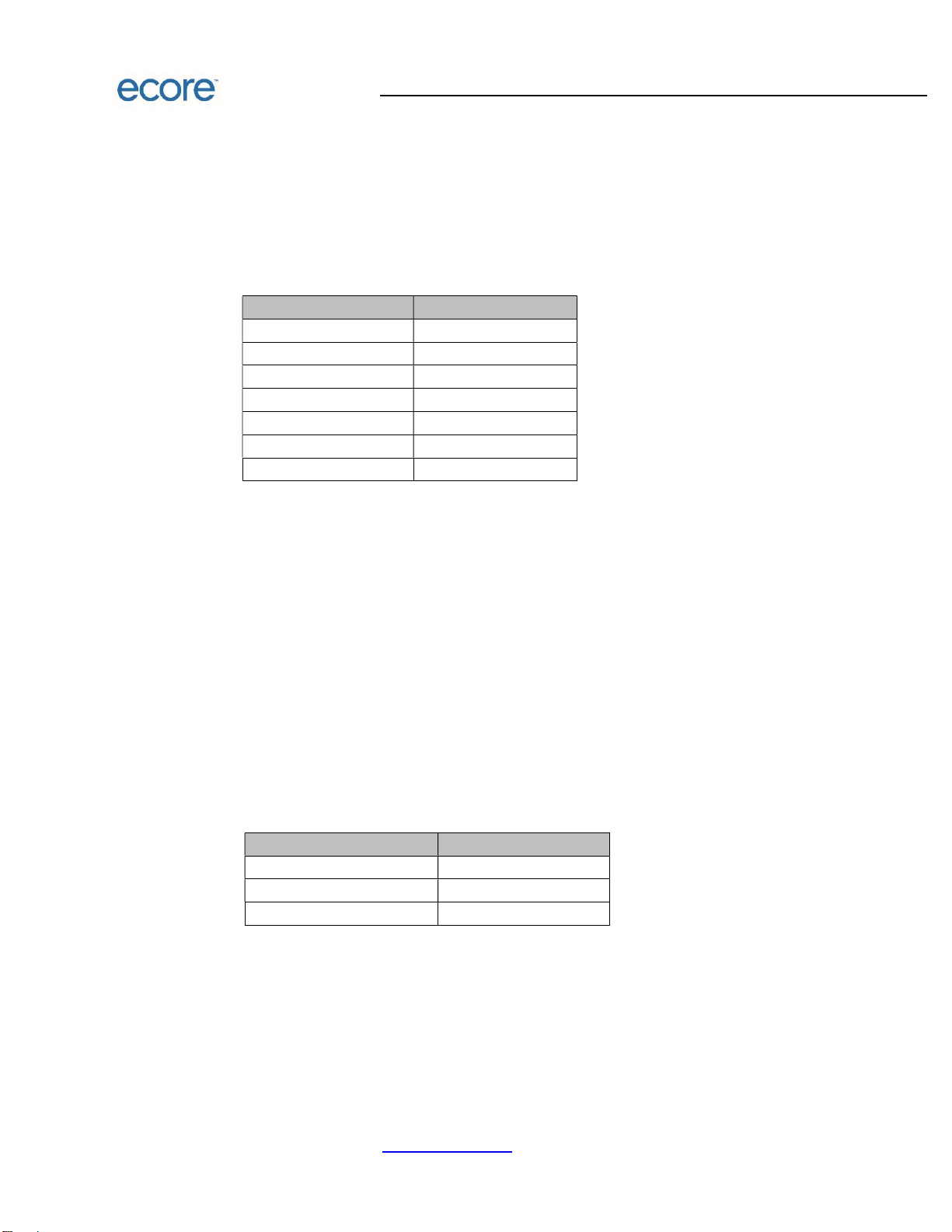

Ecore RageTurf dBTile can be installed per Sub-base / Surface per table below.

NOTE: Dimensional tolerance for tiles is +/- 1/8” for thickness and +/- 1/8” in width.

NOTE: Slight variance in shade is normal. It is the installer’s responsibility to inspect all

products to ensure the correct style, thickness, and color. Any moderate to severe

discrepancies should be reported immediately before beginning installation. No labor claim

will be honored on material installed with visual defects or shade variations.

REQUIRED TOOLS/ MATERIALS

1. Tape measure 2. Safety glasses

3. Chalk line 4. Standard size caulk gun

5. Saber saw 6. /8” square notch trowel

7. Saber Saw Blades (7-10 TPI wood type) 8. Mineral spirits/ denatured alcohol

9. Solvent safe rubber gloves, long cuff style 10. Cutting table (shipping pallet)

11. Utility knife and blades 12. Framing square/ metal straight edge

Interior

Exterior

Surface 24" x 24" x 2-1/2" 24" x 24" x 2-1/2"

Quad Blok Only 1

Quad Blok +

Full Glue 1,2

Quad Blok Only 1,4

QuadBlok +

Full Glue 1,2

Concrete Slab Approved Approved Approved Approved

Asphalt Surface Approved Approved Approved Approved

Plywood Approved Approved Approved No

Compacted Gravel 3 No No Approved No

Wood or Tile Approved Approved Approved No

Resilient Flooring Approved Approved Approved No

Rubber Roofing 4 N/A N/A Approved No

Please note:

1. Tile must always be glued to top of Quad Blok

2. “Full Glue” requires full spread adhesive using 1/8” square notch trowel. Bond test is recommended;

installer responsible to determine suitability.

3. Compacted Gravel sub-base may experience movement and subsidence. Subbase out-of-flatness,

movement, subsidence, etc. are warranty exclusions.

4.

Only adhere tile to Quad Blok connector; do not glue Quad Bloks or Tiles to the roof.

www.ecoreintl.com 3

RageTurf dBTile Technical Manual

II. SITE WORK

A. Site Elevation

1. On grade installation - The finished installed height of the RageTurf dBTile surface will be

equal to or slightly higher than the perimeter grade but not more than 1" higher unless

approved by the project engineer.

2. Above grade installation - The installation of Tile over existing decks or slabs is referred to as

an “above grade installation” and will usually require the use of reducers around the

perimeters of the area to transition smoothly back to the floor elevation unless the site

terminates at a wall or other vertical surface.

B. Site Slope / Drainage

1. Allow for 1” in 8 LF slope for drainage as applicable.

2. Provide for drainage system to eliminate standing water.

III. BASE OPTIONS

A. Hard Base Construction

1. Concrete Base

a. Minimum 3000 psi and cured for a minimum of 28 days before installation. A light broom

finish is best if fully adhering the tiles.

b. If outside, provide a minimum slope equal to 1/8" per ft of run toward drain or down-grade

side of site, flat to the equivalent of 3/16˝ (4.8 mm) in 10´ (3.0 m).

c. If inside and requiring full adhesion to concrete, concrete RH (relative humidity) must

be measured per ASTM F2170. Moisture content should not exceed the allowable limit of

the selected Ecore adhesive.

E-Grip III – RH limit of 85% – normally selected

E-Grip 95 – RH limit of 95% – higher RH applications

E-Grip 99 – RH limit of 99% – highest RH applications

If RH levels exceed the selected Ecore adhesive’s RH limit, stop and correct situation.

If outside, simply use E-Grip III

d. In the event that a moisture mitigation system is required, it must conform to the ASTM

F3010 Standard Practice for Two-Component Resin Based Membrane Forming Moisture

Mitigation Systems for use Under Resilient Floor Coverings.

e. Perform pH tests on all interior concrete floors per ASTM F3441 Testing Concrete pH for

Resilient Flooring. If greater than allowable limit of selected Ecore adhesive, neutralize

prior to installation.

2. Paved Asphalt Base

a. Provide min. slope of 1" per 10’ of run toward drain or down-grade side, with base flat to

the equivalent of 3/16˝ (4,8 mm) in 10´ (3,0 m). Light broom finish is best if fully adhering

tiles.

www.ecoreintl.com 4

RageTurf dBTile Technical Manual

b. The preferred aggregate size is 3/8" to ½". Asphalt mixtures that contain a high

percentage of fines may not be stable in hot weather and may become soft.

c. The soil subgrade must be compacted with a min. of two passes of a 10-ton vibratory

roller with no soft or moving areas upon completion. The crushed stone base must also

be compacted with a min. two passes of a 10-ton vibratory roller. The binder and wear

courses of the asphalt must both meet 95% of the theoretical maximum density of the

JMF (Job Mix Formula).

d. New asphalt surfaces should be allowed to cure for 28 days before adhering tiles.

Analysis of Asphalt Wear Course

Total Passing Sieve Percent by Weight

½" 100

3/8” 80-100

#4 45-90

#8 30-65

#50 5-25

#200 2-8

Asphalt Cement 6-8

B. Compacted Loose Base Construction

1. In outdoor areas or areas with no walls or confines, a perimeter footer will need to be

constructed to contain the compacted base and stone dust.

2. Excavate approx. 9 inches of soil below the required finished tile level. Prepare approx. 6

inches of compacted, crushed stone followed by one inch of stone dust on top. Allow for a 1”

in 10 LF slope for moisture movement to drainage pit as applicable. Some bases may require

a perforated drainpipe to remove moisture build-up.

3. By adding additional stone and compacting to the top of concrete footer, the tile can be laid

over the top of the footer concealing it, if so desired.

4. The crushed stone must be compacted to 95% standard proctor compaction and should be a

homogeneous mix suitable for and available in your geographic area. One example mix might

be:

Total Passing Sieve Percent by Weight

3/8” 100

#4 85-100

#100 10-30

5. Cover the entire stone dust area with geo-textile fabric, including the top of the footer if the

tile extends over the footer. Overlap successive geo-textile sections a minimum of 4". The

geo- textile should be permanently adhered to the top of the entire footer on all sides.

NOTE: Compacted Gravel sub-base may experience movement and subsidence. Subbase

out-of-flatness, movement, subsidence, etc. are warranty exclusions.

www.ecoreintl.com 5

RageTurf dBTile Technical Manual

C. Radiant Heat

1. 2-1/2” RageTurf dBTiles are not recommended over radiant heat as the Tiles have an R-1

per inch of thickness, resulting on an approximate R-Value of R 2-1/2 . Check with radiant

system heat manufacturer for suitability. Turn off heat and maintain slab at 65F for 48 hours

before, during and 48 hours after installation. Then bring radiant heat temperature up

gradually.

IV. MATERIAL STORAGE AND HANDLING

A. Shrink wrap is to secure and stabilize material on pallet during shipment only. Please remove

shrink wrap from pallet immediately upon receipt, as damage to material could result from not

doing so. After removing shrink wrap, do not expose material to sunlight. Store appropriately

inside and securely cover for protection until installation.

B. Inspect all material for visual defects before beginning the installation. Verify the material

delivered is the correct type, thickness, and amount. Report any discrepancies immediately.

Ecore will honor no labor claim on material installed with any visually apparent defects.

C. The material and any adhesive must be acclimated at room temperature for a minimum of 48

hours before starting the installation.

V. SITE LAYOUT AND DETERMINING TILE INSTALLATION STARTING POINT

A. Sweep area clear of all dust and loose debris.

B. Determine a starting point for the first course of tile to best suit the site area. Because most walls

are not straight or corners square, tile installation generally starts in the middle of the room, so

measure the width and length of the space, divide the room into 4 equal quadrants and snap

chalk lines that are perpendicular (90 degrees) to each other.

C. Adjust the starting point side-to-side so you don’t end up with small cuts of tile against the walls.

Place the first tile’s edges where the (adjusted) two perpendicular chalk lines meet. The last row

will most likely have to be cut to fit.

NOTE: Trimmed / partial tiles may require additional underneath site-engineered support.

VI. QUAD BLOK INSTALLATION

A. Quad Blok installation is the most efficient method of installation.

B. Follow the Site Layout instructions to prepare area for installation. Once chalk lines are made,

place first tile at intersection of two chalk lines, aligning adjacent edges of tile with chalk lines.

C. Apply a continuous 3/8” diameter bead of E-Grip III adhesive along the center axis of all Quad

Blok connectors. Insert tile into Quad Blok WHILE ADHESIVE IS STILL WET. Adhesive working

time is dependent upon environmental conditions.

D. Fit the first tile with four prepared Quad Blok connectors by lifting each tile corner slightly, sliding

the connectors under each corner and engaging the four corner legs of each tile with the

respective openings in the Quad Blok. Continue to sequentially lay the tile and to set the Quad

Bloks along one chalk line until the first course of tile is complete.

NOTE: In the field, cut the Quad Blok connectors in half to properly secure tile around the perimeter

edge of surface area.

E. Complete the other three quadrants in a similar fashion. Depending on workforce availability,

one or more quadrants can be worked on simultaneously using the above method.

www.ecoreintl.com 6

RageTurf dBTile Technical Manual

F. Allow 24 hours for adhesive to cure before opening area for use.

G. One 10.1-ounce tube of E-Grip III is required for approx. 10 of the 8” x 8” Quad Blocks.

VII. CUTTING TILES & ACCESSORIES

A. Tile cuts are best started with a retractable razer knife to cut the surface, finished with a saber saw

and a 7-10 TPI wood cutting blade. Blade must be long enough to penetrate tile.

B. Follow the Quad Blok Installation Instructions to prep site to install tile and Quad Blok connectors.

C. Avoid leaving a cut edge of a tile exposed to foot traffic or eyesight. For a finished appearance, any

tile that has its factory molded edge removed or cut for any reason should be positioned against a

wall or other vertical member. Use either a silicone sealant or a permanently elastic urethane

sealant/adhesive for filling any gaps between cut edges and walls.

D. A band saw can be used on larger jobs. Consider using silicone spray to reduce friction and blade

from binding.

E. When equipment must be bolted to the substrate below tiles, notch out tiles as required to fit tiles

around the equipment support posts.

F. Tile cutout should be approx. ¼” larger on all sides of support it will surround to prevent binding

between tile and support. Fill cutout voids with silicone sealant or a permanently elastic urethane

sealant/adhesive.

G. Lay out the tile cuts by measuring from the edges of tiles already in position and transfer

dimensions to tile to be cut.

H. Extend a lead-in cut line from the tile edge to the portion to be cutout. The lead-in cutting line

should either be the shortest distance from the cutout to a tile edge or one that is least noticeable.

I. Reducers installed at the corners should be miter cut to fit.

www.ecoreintl.com 7

RageTurf dBTile Technical Manual

VIII. FULLY ADHERED INSTALLATION

A. Use 1/8” square notch trowel.

B. Quad Bloks are recommended for fully adhered installations for ease in keeping corners aligned

and tile lines straight; include the 3/8” bead of adhesive per the Connector Detail diagram above.

C. If inside and requiring full adhesion to concrete, concrete RH (relative humidity) must be

measured per ASTM F2170. Moisture content should not exceed the allowable limit of the selected

Ecore adhesive.

a. E-Grip III – RH limit of 85% – normally selected

b. E-Grip 95 – RH limit of 95% – higher RH applications

c. E-Grip 99 – RH limit of 99% – highest RH applications

If RH levels exceed the selected Ecore adhesive’s RH limit, stop and correct situation.

If outside, simply use E-Grip III

D. In the event that a moisture mitigation system is required, it must conform to the ASTM F3010

Standard Practice for Two-Component Resin Based Membrane Forming Moisture Mitigation

Systems for use Under Resilient Floor Coverings.

E. Perform pH tests on all interior concrete floors per ASTM F3441 Testing Concrete pH for Resilient

Flooring. If greater than allowable limit of selected Ecore adhesive, neutralize prior to installation.

Maintenance

The following procedures are key in helping to preserve your turf:

I. Keep it clean

A. Dust, pollen, and airborne pollutants

For lightly soiled areas, it may be necessary to use a rectangular microfiber mop with three (3)

ounces of E-Cleaner per gallon of water. For heavily soiled areas, repeat procedure using a three (3)

percent solution of household ammonia in warm water followed by a thorough rinsing with warm

water. A wet vacuum can be used to remove excess water from the surface.

B. Stains and other blemishes

The first rule is promptness. It is always easier to clean up a fresh spill than one that has dried and

hardened. Remove any solid or paste-like deposit with a spatula or table knife. Blot up excess liquids

with paper towels, a clean cloth, or a dry absorbent, such as kitty litter or fuller’s earth. Dry

absorbents can then be vacuumed up afterwards.

Synthetic fibers have high resistance to staining. However, it is important to realize they are only one

part of a sophisticated system of various components designed for overall performance. Some

cleaning agents safe for the face fibers can be harmful to other components of the turf system.

www.ecoreintl.com 8

RageTurf dBTile Technical Manual

Therefore, cleaning agents are grouped into two sets, one of which can be used in liberal amounts

directly on the turf surface, and the second of which should only be applied by rubbing a cloth lightly

soaked in the cleaner in order to minimize penetration of possible harmful agents below the turf

surface.

In the first group of cleaners, which generally can be applied without any special precautions, are

the following:

A warm, mild solution of granular household detergent or any low sudsing detergent

for fine fabrics. Use approximately one teaspoon to one pint of water. This will handle

most waterborne stains including:

Coffee

Cola Tea Blood

Ketchup Milk Ice Cream Urine

Mustard Cocoa Butter Dye

Fruit juices

Vegetable

juices

Glue Latex paint

A three (3) percent solution of ammonia in water may be used in lieu of household

detergent for more stubborn stains.

Do not use cleaners that contain chlorine bleaches or caustic cleaners (pH above 9)

or highly acidic cleanses (pH below 5). Use only neutral cleaners such as E-Cleaner

provided by Ecore.

Rinse area thoroughly with clean warm water to remove any traces of soap or

ammonia.

Blot up excessive liquid.

The second group of cleaners, where agent must be applied sparingly and care taken to avoid

penetration beneath the turf, are the following:

Mineral spirits or a grease spot remover like perchlorethylene (dry cleaning solution) of

the type sold by most variety stores and supermarkets. In general, cleansers in this

category should handle most oil-based stains including:

Asphalt Motor oil & grease Chewing gum Lipstick

Tar Suntan oil Crayon Nail polish

Shoe polish Cooking oil Ballpoint ink Floor wax

Caution: Mineral spirits and other petroleum-based solvents are flammable. Do not smoke

or permit open flames near where these are being used. Be sure the area is well ventilated

where solvent cleaners are used and remember to use sparingly.

C. Animal waste

Neutralize with mixture of white distilled vinegar in an equal amount of water. Flush thoroughly with

water after application. And vacuum up excess solution with a wet vacuum.

D. Chewing gum

In addition to dry cleaning fluid, chewing gum can be removed by freezing. Aerosol packs of

refrigerant are available from most carpet cleaning suppliers for this purpose, or dry ice can be used.

After freezing, scrape with a knife.

www.ecoreintl.com 9

RageTurf dBTile Technical Manual

E. Fungus or mold spots

A one (1) percent solution of hydrogen peroxide in water can be sponged on to the affected area.

Flush thoroughly with clean water after application.

II. Periodic brushing

A. Matting of fibers may occur in areas of high foot traffic, especially if fibers have become soiled with

dirt and other airborne pollutants.

B. Periodic “cross brushing” of the turf can help restore its aesthetic appearance. “Cross brushing”

means all brushing activity takes place against the grain, nap, or sweep of the turf fibers. By

brushing against the turf, the fibers are “fluffed up.” A brush with synthetic bristles should be used.

Never use a brush with metal or wire bristles as these will change the turf fibers.

III. Do not abuse

Although turf is made of tough, durable fibers, certain precautions should be taken to prevent any

damage.

Lighted cigarettes cannot ignite the turf, but permanently damage the turf.

Furniture & equipment with sharp or jagged edges may puncture or tear the turf.

Sprinkler or hard water can leave mineral deposits that may cause discoloration.

Heat from reflected sunlight may fuse the turf fibers together.

Minor problems can become major problems quickly if not corrected. The proper care and

maintenance program can enhance the aging, usefulness, and aesthetics of the turf.

Warranty

All Ecore RageTurf dBTile Tiles are guaranteed to be free from manufacturing defects on both material and

workmanship. If such a defect is discovered, the customer must notify Ecore either through the contracting

installer, distributor, or directly. If found to be defective under normal non-abusive conditions, the sole remedy

against the seller will be the replacement or repair of the defective goods, or credit may be issued not

exceeding the selling price of the defective goods. These warranties only apply to the original purchaser.

Please see the Ecore Warranty Guide for length specifics.

Ecore RageTurf dBTile Tile warranty shall not cover dissatisfaction due to improper installation, normal wear,

damage from improper maintenance or usage, or general misuse, including and without limitation: burns, cuts,

tears, scratches, scuffs, damage from rolling loads, damage from cleaning products not recommended by

Ecore, slight shade variations or shade variations due to exposure to direct sunlight, or differences in color

between samples or photographs and actual flooring.

Warranty Exclusions

1. Disfigurement or damage caused by abnormal use or any damage not arising from a defect.

2. Differential fading due to light exposure, shading, pile crush, dye lot differences, and soiling.

3. Any condition that would have had a visible defect upon inspection prior to installation.

www.ecoreintl.com 10

RageTurf dBTile Technical Manual

4. Damage from any use for which the product was not designed.

5. The exact matching of shade or color.

6. Any express or implied promise made by any salesperson or representative.

7. Tears, burns, cuts, or damage due to improper installation, improper use, or improper cleaning agents or

maintenance methods.

8. Labor costs for installation of original or replacement material.

9. Sale of “remnants,” “seconds,” “off goods” or other irregular (non-first quality) flooring materials, are sold

“as is,” and Ecore makes no warranties whatsoever, express or implied with respect thereto, including

warranties of merchantability or fitness for a particular purpose.

10. Problems caused by moisture, hydrostatic pressure, or alkali in the sub-floor.

11. Problems caused by uses, maintenance, and installation that are contrary to Ecore specifications,

recommendations, or instructions.

12. Material installed with obvious defects.

13. Material that is not installed and maintained as recommended by Ecore.

14. Damage to flooring products from pallet jack and tow-motor or vehicular traffic.

15. Environments where the product will be exposed to animal fats, vegetable oils, grease, or petroleum-based

materials. (i.e.: commercial kitchens or auto repair facilities.)

16. Premature wear and deterioration from spikes or natural grass cleats.

17. Differences in color between products and photography.

This warranty is in lieu of any other warranty, whether expressed or implied, including but not limited to

any implied warranty of merchantability or fitness for a particular purpose. Ecore shall not be liable for

incidental or consequential losses, damages or expenses directly or indirectly arising from the sale,

handling, or use of the materials (goods), or from any other cause relating thereto. For complete and

latest warranty information, please visit www.ecoreintl.com

Manufactured in the U.S.A. by:

866-795-2732 – www.ecoreintl.com

715 Fountain Ave – Lancaster, PA 17601

© 2023 All designs and colors are copyrighted by Ecore.

Table of contents

Other E-Core Fitness Equipment manuals

Popular Fitness Equipment manuals by other brands

NordicTrack

NordicTrack Commercial X22i user manual

Hoist Fitness

Hoist Fitness RPL-5405 owner's manual

ergolet

ergolet Pallas 2000 user guide

Ironman Fitness

Ironman Fitness Gravity 4000 owner's manual

Stairmaster

Stairmaster SC5 StairClimber owner's manual

Taurus

Taurus PTT0215 Assembly and operating instructions