E-Seek M500 Manual

Cleaning Procedure for

M500 Scanner

SCANNER MAINTENANCE

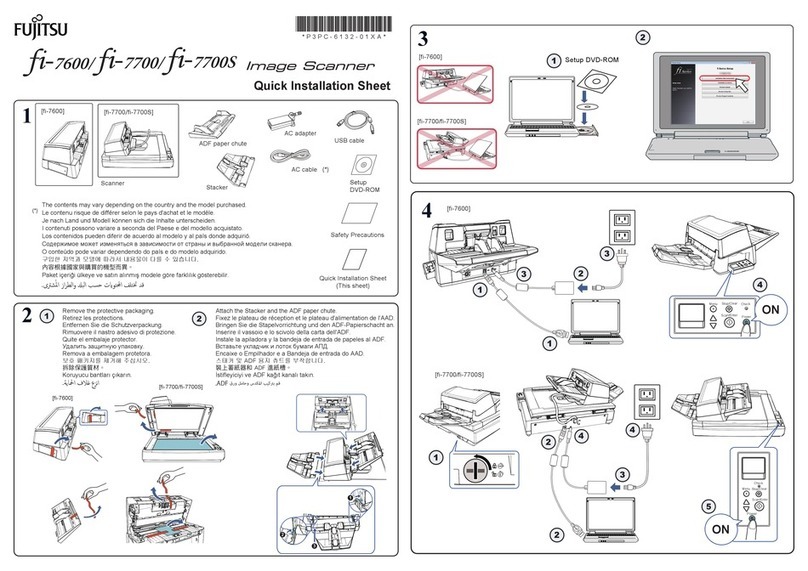

There are two distinct cleaning procedures for the M500 scanner that completes two separate functions:

The first procedure involves a special cleaning card that we offer either in singles or in bulk. The card is saturated,

presumably in an alcohol solution and is meant to clean the rollers and magnetic stripe reader head. These are surfaces

that are in direct contact with the IDs that are scanned and the rate of soiling of these surfaces depends on the average

cleanliness of IDs scanned as well as the scan volume. One uses the card by simply inserting it into the M500; the rest is

automatic. We recommend that this is done monthly in step with the monthly updates; however, depending on scan

volume, this is not strictly necessary. If you scan much more than 10,000 IDs a month and especially if you approach

20,000 scans a month, the cleaning should be completed monthly. Otherwise it can be done roughly every two to three

months.

The second procedure is somewhat more complex and requires three items. These items are a calibration card, an air

divider (a specially-made plastic tool) and an aerosol can of electronics duster. This procedure cleans the mirrors that are

located on the sides of the ID card slot. The instructions for this procedure are detailed below with pictures included.

The particularly tricky part, at least the first time someone does it, is getting the air divider in place. Our best piece of

advice is to look closely at the photos in the manual and realize that the tool will almost "snap" into place when inserted

properly. The calibration card and air divider are replaceable; however, you should take care to keep them in good

condition and avoid misplacing them. The calibration card should be put into its protective sleeve when not in use and

should be disposed of when it becomes at all scratched or dirty. This process is also recommended to be completed

monthly though if horizontal streaking is noticed in the scanned image, someone should complete the procedure

immediately. If some types of debris are left in place on the mirrors, they may become adhered and therefore difficult to

remove through normal methods.

The M500 package contains both a cleaning card and a calibration card. We have also included your first cleaning kit free

of charge. This kit consists of two more cleaning cards, another calibration card, an air divider tool and one can of

Ultrajet 70 aerosol duster. You don't strictly need to use Ultrajet 70 though it is recommended. The duster you use must

be free of residue and preferably not be flammable. There are other brands that meet these criteria; however, we have

not found them to be roughly the same cost as Chemtronics Ultrajet 70. Please do not use the kind that cost $5-$10.

Dust lines / yellowing at top of image

M500 MAINTENANCE VIDEO

https://youtu.be/jNPWMe08hu4

CALIBRATION CARD

The main Purpose of the White Calibration Card is to perform a white color balance calibration. This calibration occurs

when the Calibration Card is inserted into the M500 with the ARROW FACING IN towards the M500. (See the

Calibration Card illustration below) . When this Calibration process is performed, an EV_WHITE_CAL event will occur,

which will cause certain settings to be calculated and stored within the M500. During this process, the data displayed

through the application software will be the previous calibration settings. The new settings will not be displayed until

the next scan. These settings are used for color balance calculations within theM500 during normal scanning operation.

The secondary purpose of the White Calibration Card feedback in the determination of whether or not dust or debris

may have accumulated on the M500’s mirrors. The Verification Process occurs when the Calibration Card is inserted into

the M500 with the ARROW FACING OUTWARD. When this is performed, an EV_WHITE_CALV will occur. At this point,

the application software should display RGB images to the user to facilitate the determination of whether or not there

is dust or debris on the mirrors. Note. The Verification process does NOT re-calibrate theM500.

Calibration Card

The cleaning card is designed to clean the internal rollers and the Magnetic Read Head inside theM500. The need for

cleaning varies, but is primarily dependent on the usage or the number of card scans. The general guideline is for

cleaning once a month for high usage and once every three months for low usage environments. This process is very

simple to perform as it is an automatic process once the cleaning card is inserted into theM500.

Alternatively, you can purchase a 3rd party cleaning card. We have tested and recommend the KICTeam Waffletechnology

Cleaning card, available on Amazon here.

https://www.amazon.com/gp/product/B007X3S5O0/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1&pldnSite=1

AIR CLEANING

Even though the M500 is basically a sealed unit, dust and debris can, over time, accumulate inside the scan path,

and in particular on the mirrors inside the unit. The detection process should be performed in a periodic basis to assess if

dust has degraded the image quality. Every 10000 to 20000 cards scanned, the mirror inside the M500 will need to be

checked for dust and cleaned.

The Detection and Cleaning process for the M500 mirrors requires the following items:

1. Calibration Card, this card is designed and made by E-Seek, Item # M500-CALIB.

2. M500 path Air Diverter, a plastic part made to block the scan path and divide the air flow, Item # M500-

AIRDV.

Air Diverter

3. Air Duster, aerosol can of compressed air. The preferred air duster is designed to leave no residue with a high

filtration. The non-flammable model of the product is preferred. The following Brand has been used and tested

by E-Seek. Chemtronics Ultrajet 70.

https://www.chemtronics.com/p-844-ultrajet-70.aspx

There are three parts to maintain the M500:

Verification (Step 1-2)

Cleaning (Step 3-5)

Calibration (Step 6-7)

Step 1: Insert the Calibration Card with the arrow facing outward (away from theM500).

Calibration card inserted with arrow facing outward

Step 2: Verifying that the dust/debris exists on the mirrors.

Calibration card Image from application

Note the horizontal dust lines at top of the card

If there is dust on the mirrors, you will see a dust line (as illustrated by the number 1 on the figure below) on the left

section (number2) of the image. The Left section (number 2) is the uncorrected side of the image and the Right Section

(number 3) is the corrected side of the image. This method helps to see the raw uncorrected image which allows the

dust line to be visible. If such a line exists there is dust on the mirrors, and you should proceed to the Cleaning process,

Step 3.

Step 3: Cleaning Process. Open the M500 side door and insert the Plastic Air Divider.

Air Divider Plastic insert

1. Insert the Air Divider down inside the M500 into the opening.

2. Position the Air Divider under the top spring loaded line (Grey

Plastic).

3. Align the Air Divider to the M500 side wall.

4. Push the Air Divider completely into the M500 Scan path.

Step 4: Use of the Air Duster. Insert the pressurized Air Duster nozzle into the M500 scan opening.

Air Duster operation

Follow the operational directions on the Air Duster for use. Typically, you want to press the Air Release Valve in each of

the 4 positions shown below for about 2 seconds each. Do not over use the duster in any position, if the duster gets too

cold, wait for about 10 seconds and complete the cleaning operation.

DO NOT hold the Duster upside down.

Step 5: Remove the Plastic Air Divider and close the side door of theM500. Next REPEAT only Steps 1 & 2. If you see the

Dust Line disappear in the uncorrected (Left Section of the Image), then proceed to Step 6. If the Dust Line is still present

or has moved to a new location (only on the Left uncorrected image side), then go to Step 3.

Note: Once the dust is removed from the mirrors, you may see a new line on the Corrected section (Right Side) of the

image. At this time ignore the Right side image.

Step 6: Calibration. At this point you need to calibrate the M500 without any dust present on the mirrors. This is a

simple and mostly automatic process. Simply insert the Calibration Card into theM500 with the arrow FACING INWARD.

The M500 will accept the card into the unit and goes through the calibration process automatically. Once the calibration

is complete the Calibration Card will be ejected. This operation will store the Calibration Data within the M500.

Calibration card inserted with arrow facing inward

Step 7: Completion. At this time, you can repeat only Steps 1 & 2 to verify your cleaning results. You should see the Left

image with no dust and the Right image with a clean White even background.

Other manuals for M500

1

Table of contents

Other E-Seek Scanner manuals