E-Z DRILL 210-3 EQ MT User instructions

Other E-Z DRILL Construction Equipment manuals

E-Z DRILL

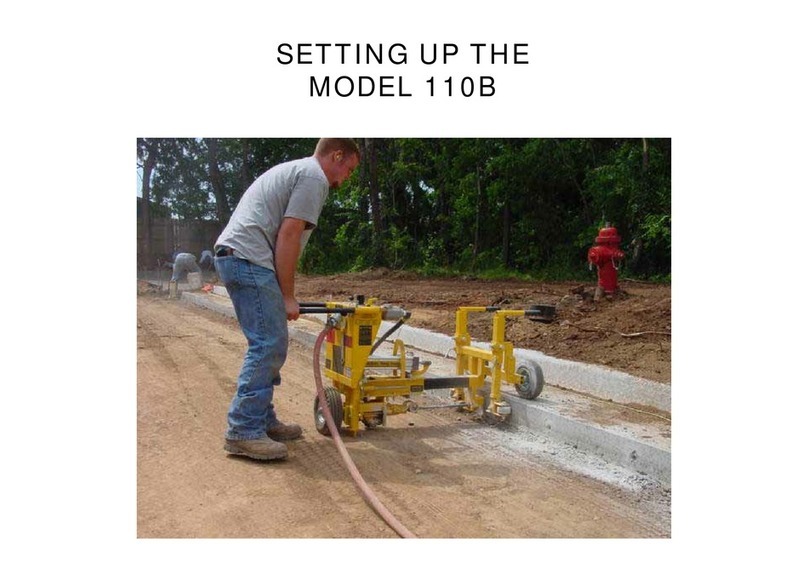

E-Z DRILL 110B User instructions

E-Z DRILL

E-Z DRILL 85B User instructions

E-Z DRILL

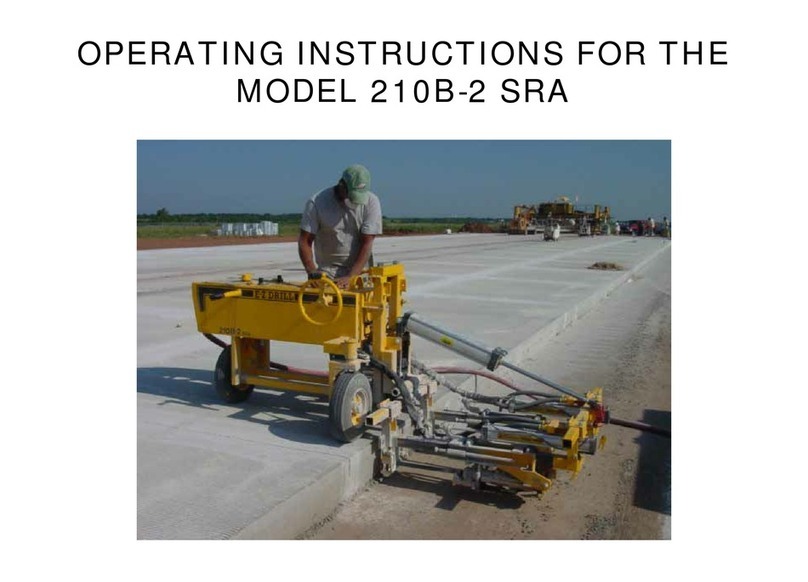

E-Z DRILL 210B-2 SRA User manual

E-Z DRILL

E-Z DRILL 110B Guide

E-Z DRILL

E-Z DRILL 210-3 SRA Guide

E-Z DRILL

E-Z DRILL 210B SRA Guide

E-Z DRILL

E-Z DRILL 210B User instructions

E-Z DRILL

E-Z DRILL 20 UTL Guide

E-Z DRILL

E-Z DRILL 210-3 EQ MT Guide

E-Z DRILL

E-Z DRILL 210B SRA User instructions