KO-IIMANUAL

3

www.eaeelectric.com

www.eaeelectric.com

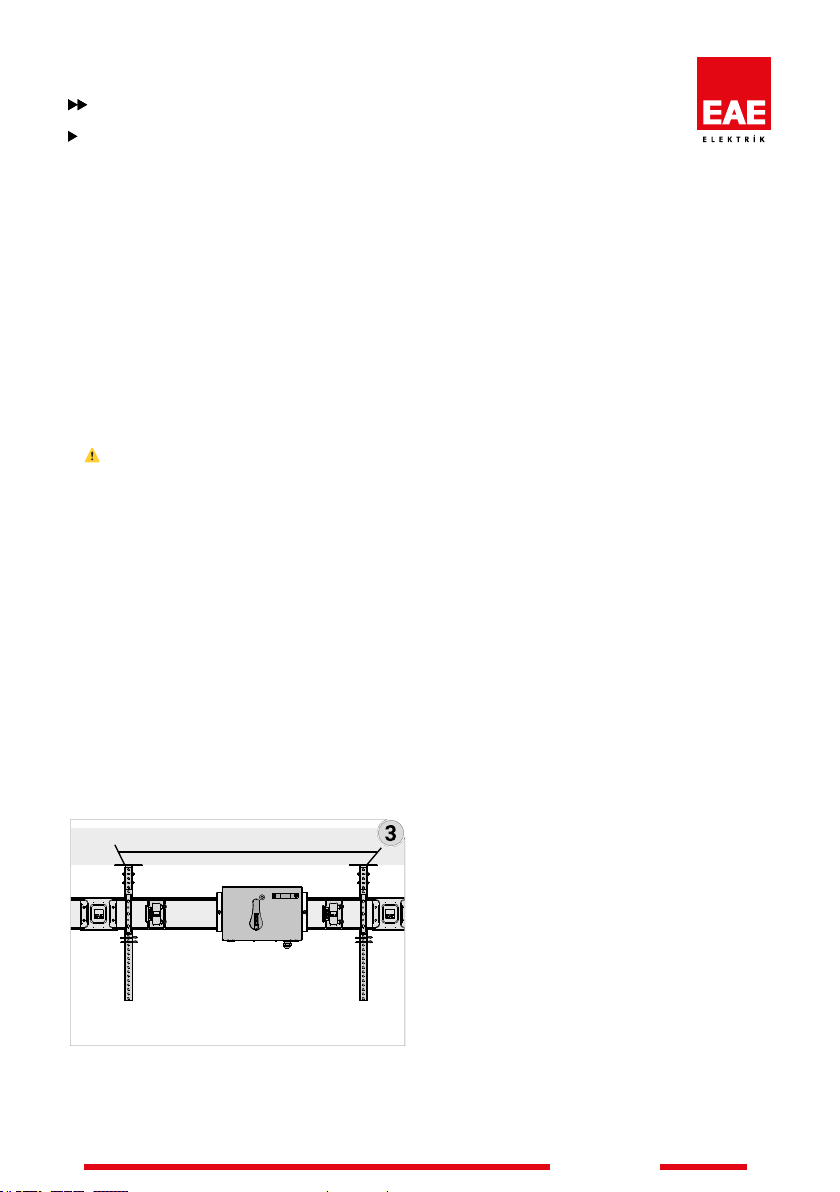

1- Installation according to the project of the

busbar system, planning and coordination with

other distribution systems (mechanical, heat,

steam, air installation etc.) is crucial.

2- Operational Success of the Busbar

systems is ensured by adhering to the right

transport, proper installation and design.

Improper application may cause malfunction

of the system, personal injury and damage to

operating systems.

3- The installation, operation and maintenance

of the busbar system should only be carried out

by qualied personnel who know the dangers

associated with installation a, construction

and operation of electrical equipment for the

purposes of this manual. Additionally, this

personnel ;

* Knows the requirement of applicable electrical

laws, other laws and standards.

* Be trained and authorized to test, energize,

clean, ground, label and lock the system and

equipment suitable for occupational safety

applications.

* Be trained in the use and maintenance

of personal protective equipment such as

rubber gloves, helmets,protective goggles or

face shields and gauze-resistant clothing in

accordance with relevant work safety practices

and potential hazard levels.

* Must be trained in rst aid.

WARNING:

Dangerous voltage levels in the electrical

components may result in the hazardous injury

and death.

Installation, monitoring and maintenance must

be carried out on de-energized busbar electrical

equipment. In this way, unintentional contact to

the equipment under the energy is prevented.

must be followed all warnings and related

instructions.

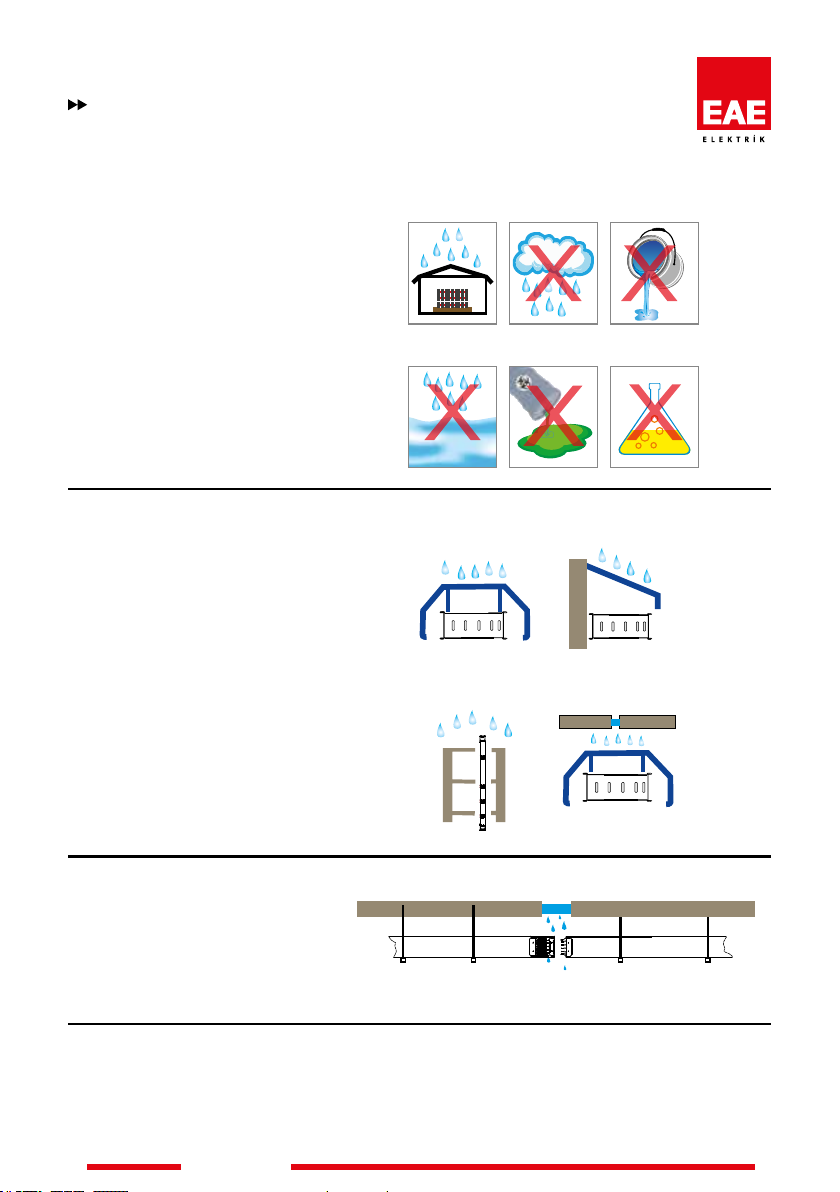

WARNING :

Operation of the busbar damaged by water or

moisture can caused damage property, serious

personal injury or death. To ensure proper

installation resistance and to ensure that the

moisture source is removed, observe the notes

in section on page 16 item 13 you receive.

General