2

Table of Contents

1. Introduction ...................................................................................................... 4

1.1 Safety Information ........................................................................................................... 4

2. Product Overview ............................................................................................ 5

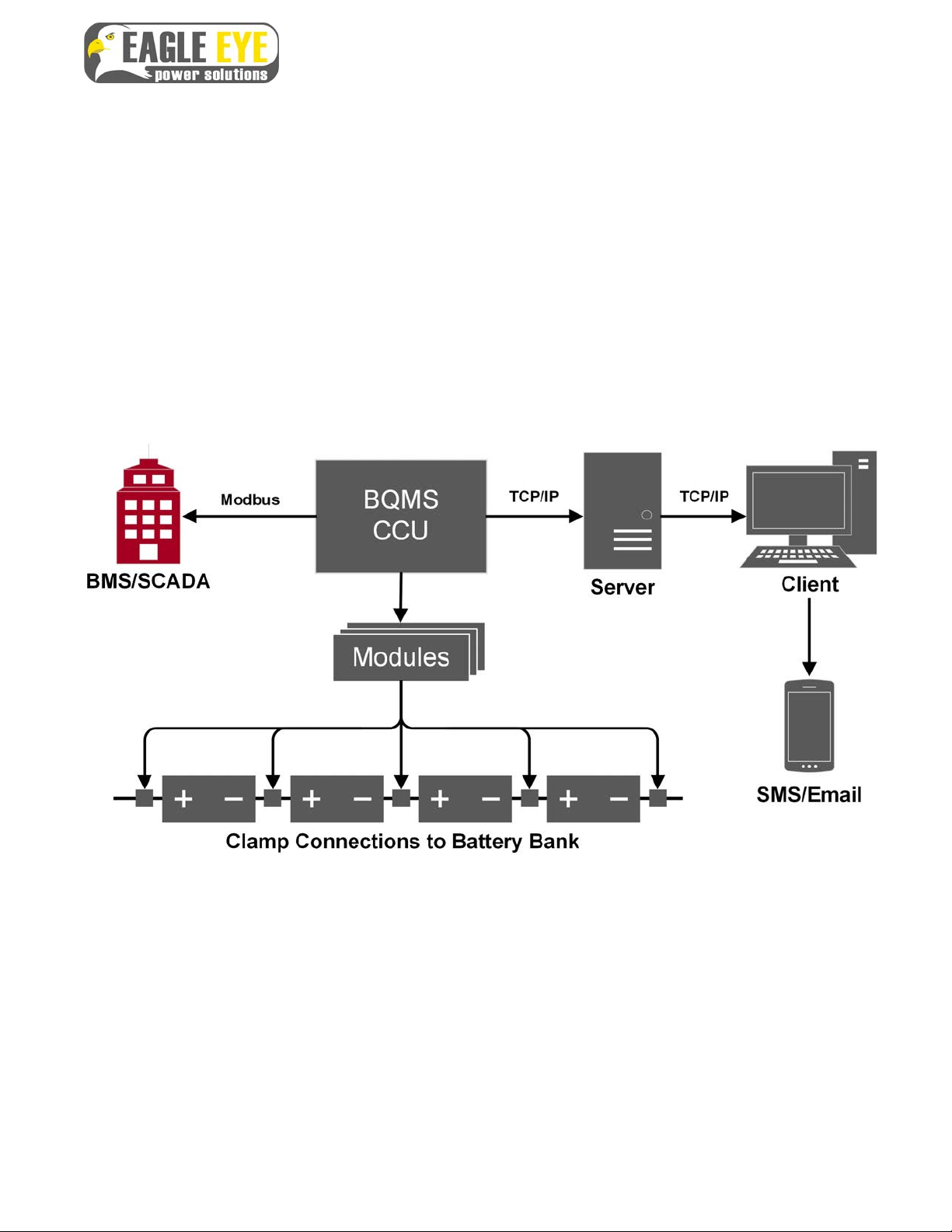

2.1 System Composition ....................................................................................................... 6

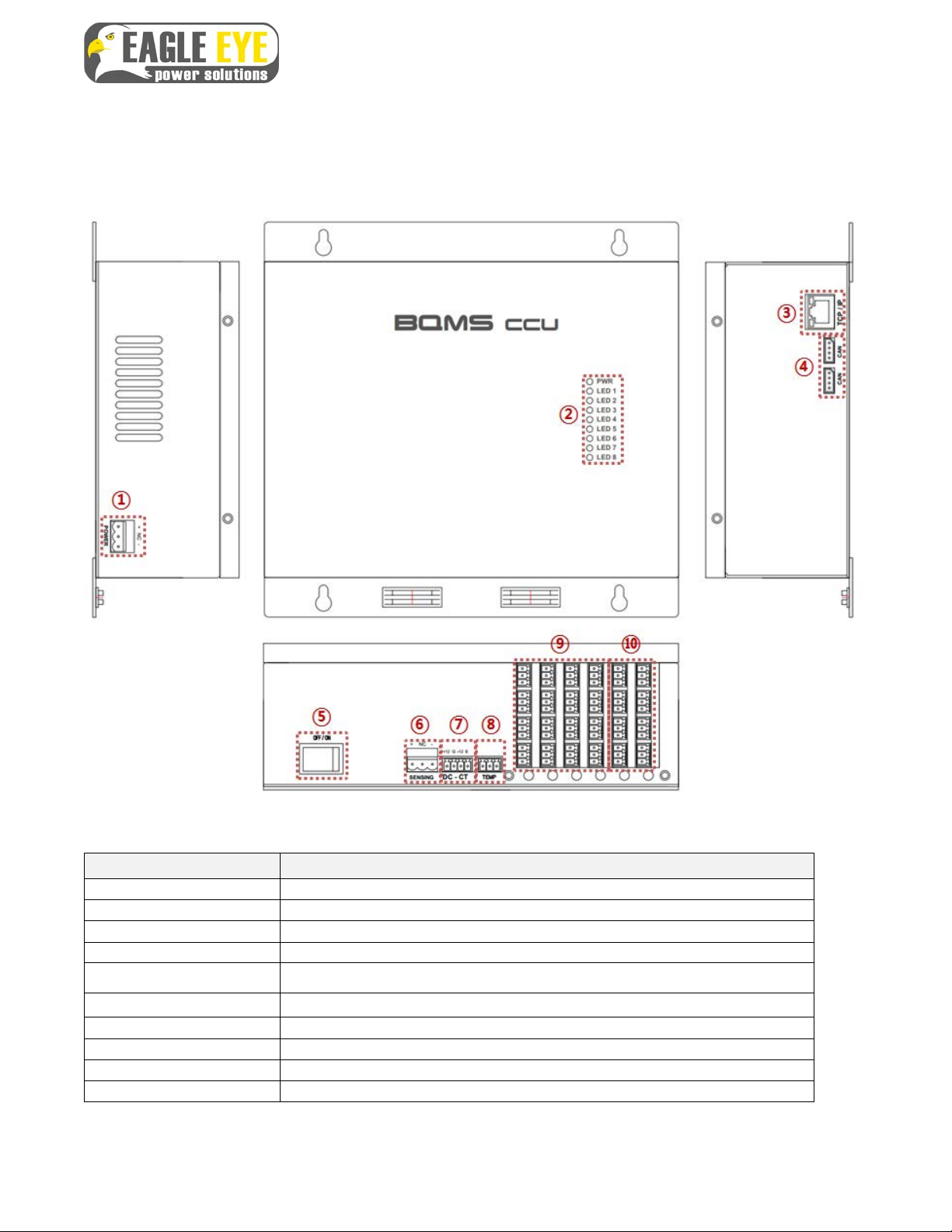

2.2 Communication Control Module (CCU) ......................................................................... 7

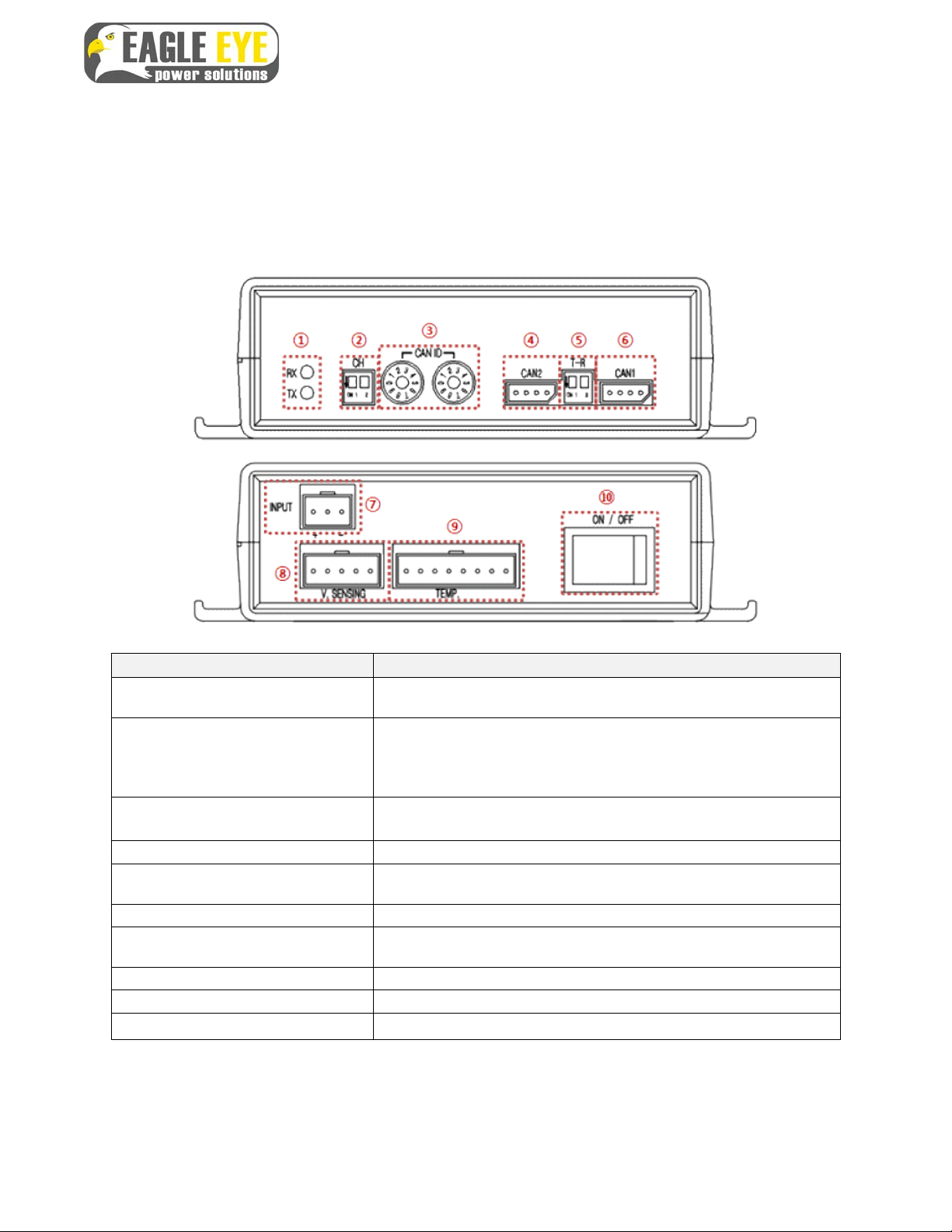

2.3 Measuring Unit Module ................................................................................................... 8

2.4 Technical Specifications ................................................................................................. 9

3. Parts List ........................................................................................................ 10

4. Installation Tools ........................................................................................... 12

4.1 Standard Installation Tools .......................................................................................... 12

4.2 Recommended Tools .................................................................................................... 13

5. Hardware Installation .................................................................................... 14

5.1 Overview of Workflow ................................................................................................... 14

5.2 Mount CCU or Cabinet Enclosure ................................................................................ 15

5.3 Check & Mount Modules ............................................................................................... 16

5.4 Clamp Installation .......................................................................................................... 18

5.4.1 Prepare for Connection ............................................................................................. 18

5.4.2 Connection of Clamps (C-Type) ................................................................................ 19

5.4.4 Connection of Clamps (O-Type) ............................................................................... 20

5.5 Sensing Cable Connections ......................................................................................... 21

5.5.1 Sensing Cable Overview ........................................................................................... 21

5.5.2 Cable Connection to 2V Cell/unit: ............................................................................. 22

5.5.3 Cable Connection to 4V Unit: .................................................................................... 23

5.5.4 Cable Connection to Multiple 12V Units: ................................................................... 24

5.5.5 Cable Connection to Single 12V Unit: ....................................................................... 25

5.5.6 Preliminary Cable Routing ........................................................................................ 26

5.5.7 Install Wire duct (Optional) ........................................................................................ 27