1-4

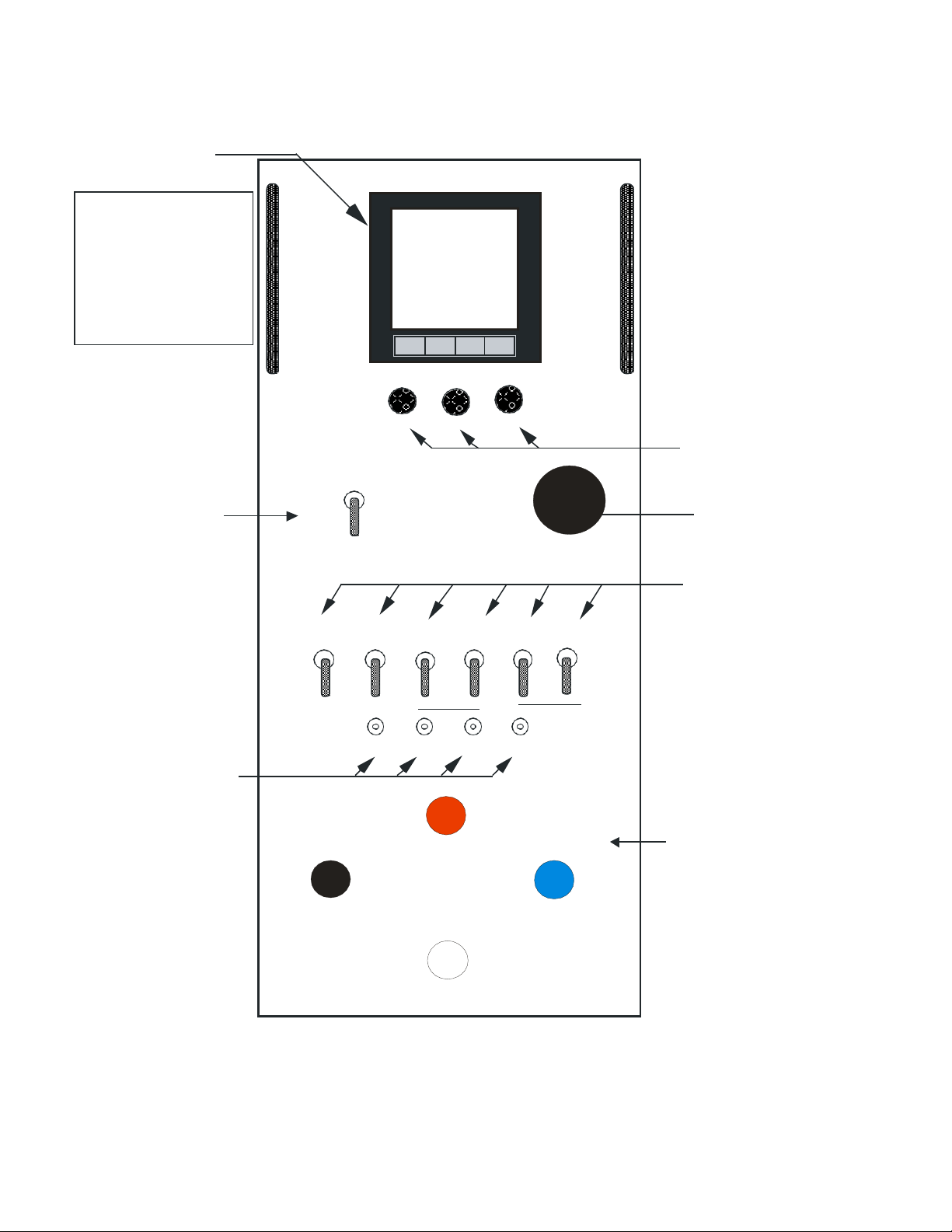

CONTROL DESCRIPTION: The following is a description of the controls on the control panel (see figure

1-2 on page 2.

DIGITAL MULTIMETER - A three phase meter used to measure, Phase Voltage (V),Phase to Neutral (V),

Frequency (Hz),Phase Current (I),Neutral Current (I),Active Power (W),Reactive Power (Var),

Apparent Power (VA), Power Factor ( P.F.), Active Energy (W.h), Reactive Energy Var.h), Instantaneous Demand

Amp, Instantaneous Demand Active Power, Instantaneous Demand Apparent Power,

Maximum Demand Amps, Maximum Demand Active Power, Maximum Demand Apparent Power.

The meter should read approximately 208 volts line to line or 480 volts line to line.

RATE SWITCHES - Switch used to select the desired rate on the load bank. The rates are as follows:

480VAC 208VAC

1.

12.5 KW balanced load 1. 5 KW or 10 KW balanced load

2.

12.5 KW balanced load 2. 10 KW balanced load

3.

25 KW balanced load 3. 20 KW balanced load

4.

25 KW balanced load 4. 20 KW balanced load

5.

25 KW balanced load 5. 20 KW balanced load

POWER INDICATOR LIGHTS - These lights will light to indicate power on A, B, and C phase. All three lights

should be on when testing three phase circuits.

METER TEST JACKS - This provides a place to connect an external meter. There is a test jack for each cable

pin.

POWER RECEPTACLE - The power cable from the equipment to be tested is plugged into the load bank

through the receptacle.

USB PORT- For monitoring and logging of meter data. Programs are included on USB jump drive located on

handle of load bank.

120 VOLT POWER RECEPTACLE - A power cable is provided to plug the unit into a 120VAC outlet.

(Not shown on drawing)