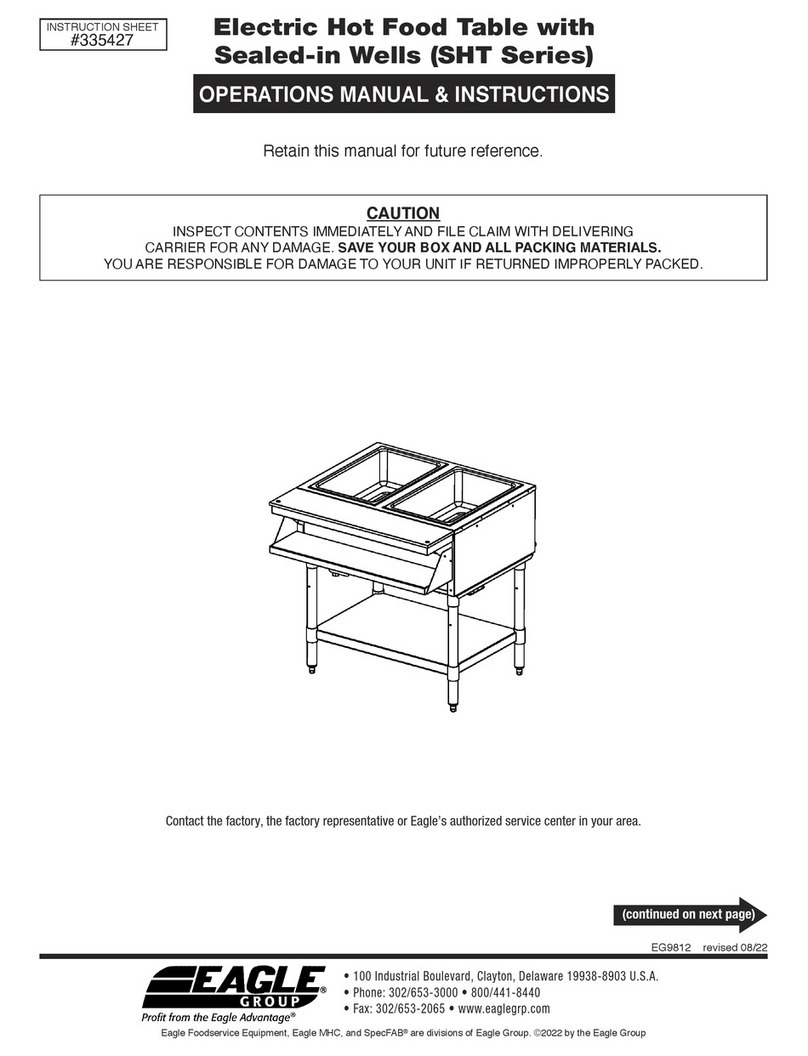

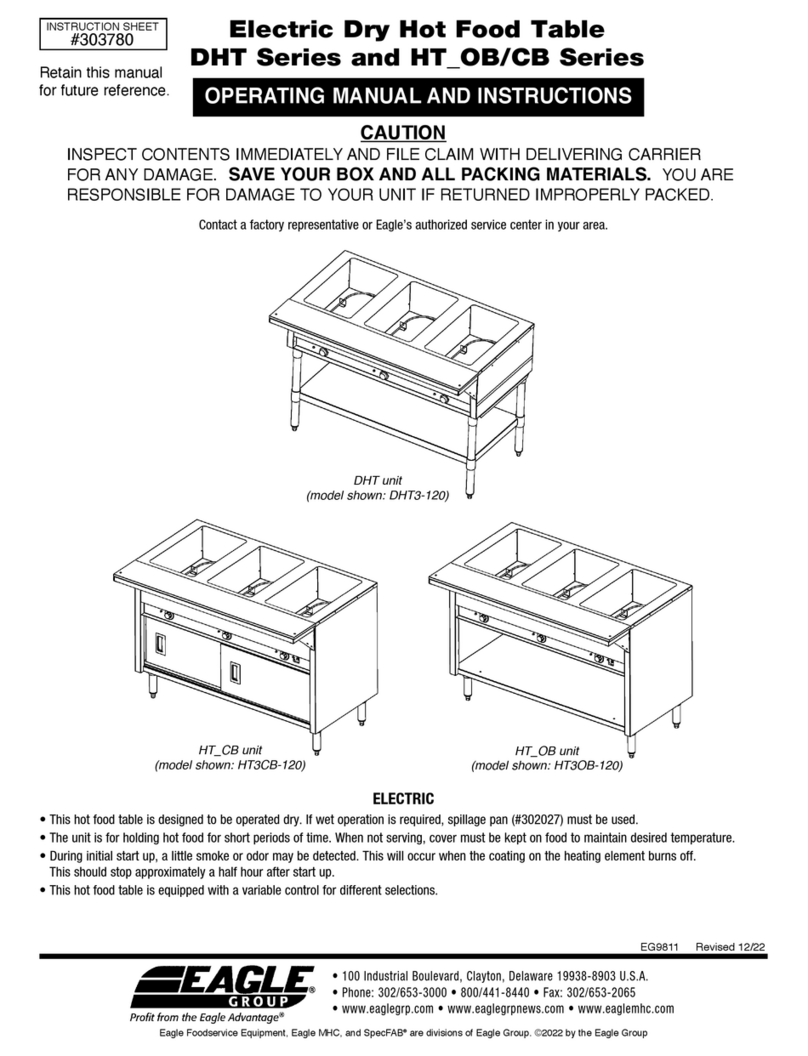

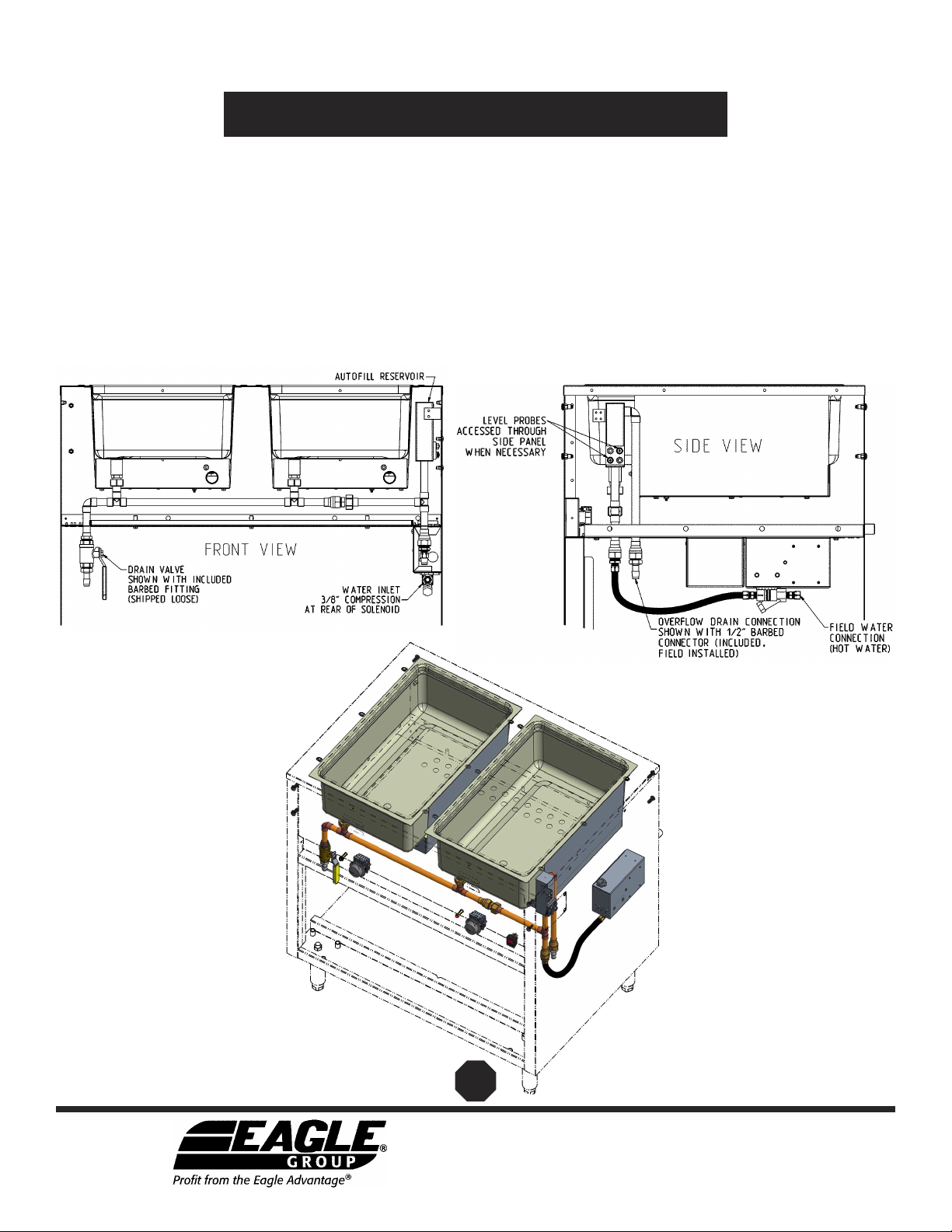

Spec-Master®Hot Food Table with Sealed-in Wells

(continued on next page)

OPERATIONS MANUAL & INSTRUCTIONS

The Hot Food Table will work most efficiently when used with hot water in the pan liner. The hot water will give a better distribution

of heat and help keep food from drying out. It is not designed for cooking foods but merely to keep cooked foods at desired

temperatures for serving.

During initial operation, a little smoke or odor may be detected. This will occur when the coating on the heating element burns off.

This should stop after a half hour of operation.

This unit is equipped with a variable control for different heat selections.

WET OPERATION WITH COVER

(IF USING AUTOFILL®, PLEASE SEE BACK PAGE)

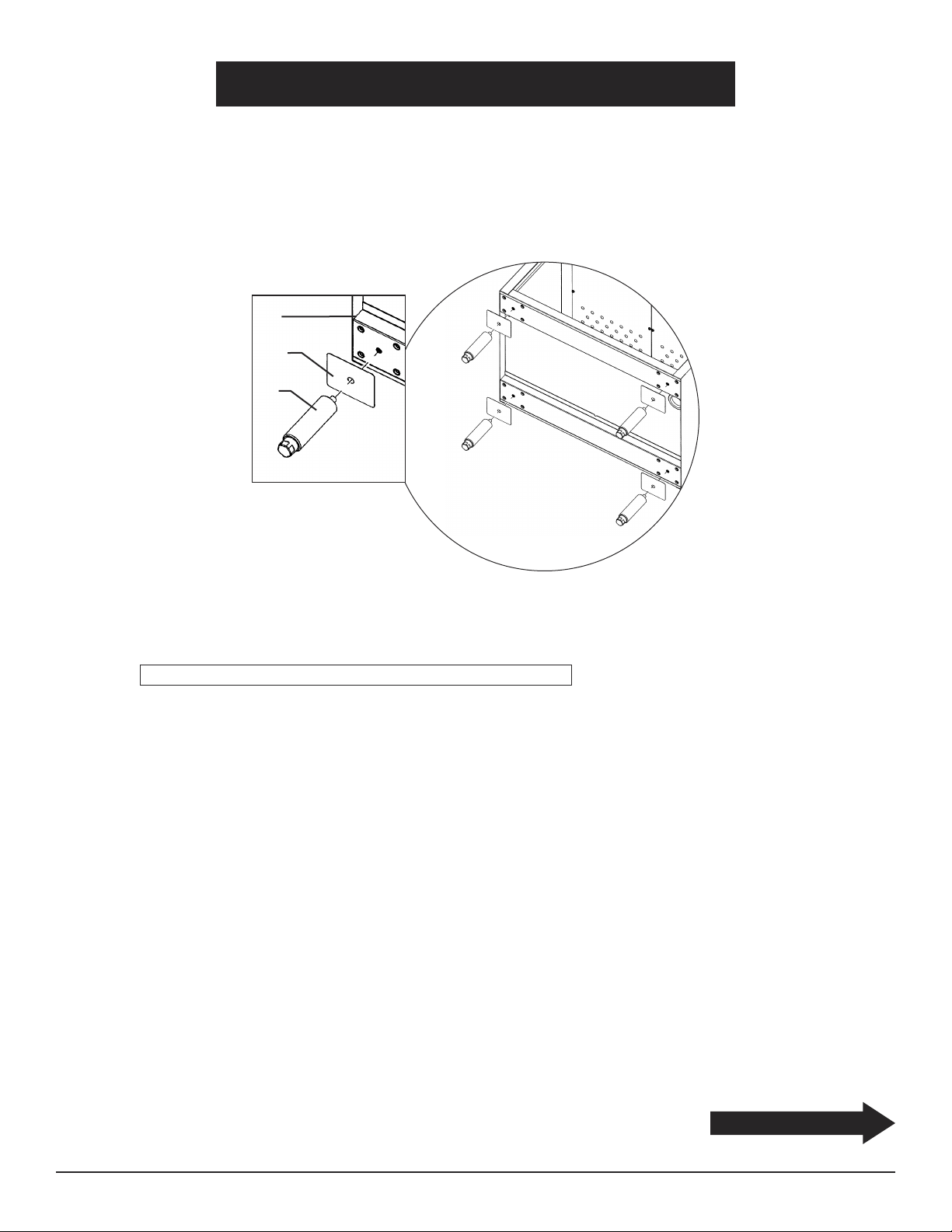

1. Ensure unit is level in both directions, adjust feet in or out as necessary.

2. Ensure drain valve is in the closed position.

3. Pour hot water (minimum of 185°F [85°C]) into first well. Water will flow through manifold and fill all the wells, stop when a depth

of about 1" has filled all the wells. This may take a few minutes to level out between all wells.

4. Set dial to highest position for 45 minutes with well covered to preheat unit, place food pan with precooked food (minimum 150˚)

into well and cover food pans with lids. (Note: Indicator light is the set point for the control knob.)

5. Adjust to desired setting for proper food temperature. This will vary with the type of food, type of pans and individual serving tem-

perature. NSF requires a minimum temperature of 150˚F in food product.

6. To increase temperature turn knob toward highest setting, to decrease turn knob toward lowest setting.

7. Change water, clean well and wipe dry after every 24 hours of operation. Water may have to be added to pan during operation

depending on operating time and temperature setting.

8. Food pans must be covered to maintain temperature when food is not being served and to prevent food from drying out.

The above instructions are starting suggestions only and may be changed to suit your individual needs. With so many different

applications for this item it is impossible to have standard settings to suit all situations.

NOTE: If unit is used dry, the bottom of the well will take on a brown colored appearance where the heater is located.

The discoloration will not come off with normal cleaning procedures, but in no way will it affect the operation of the unit.

CAUTION:

1. This equipment is designed and sold for commercial use only by personnel trained and experienced in its operation, and is not

sold for consumer use in and around the home, nor for use directly by the general public in food service locations.

2. Do not immerse unit in water.

3. All repairs should be performed by an authorized service center.

4. Unit should be turned off when not in use. It is recommended that unit be disconnected from power supply by removing plug from

receptacle or shutting off power disconnect supply to the unit.

5. Unit must be operated with legs provided to prevent overheating and damage to surface below or cord.

3