-7 -

4. Operation

4.1 Standard Operation

Prior to operating the machine, please confirm that

1. The proper power is being supplied to the machine (110V)

2. All fasteners and protective covers are securely in place

3. All electronic components are dry

Machine Operation

1. Plug the machine into the power source

a. DO NOT hard wire the machine to the power source

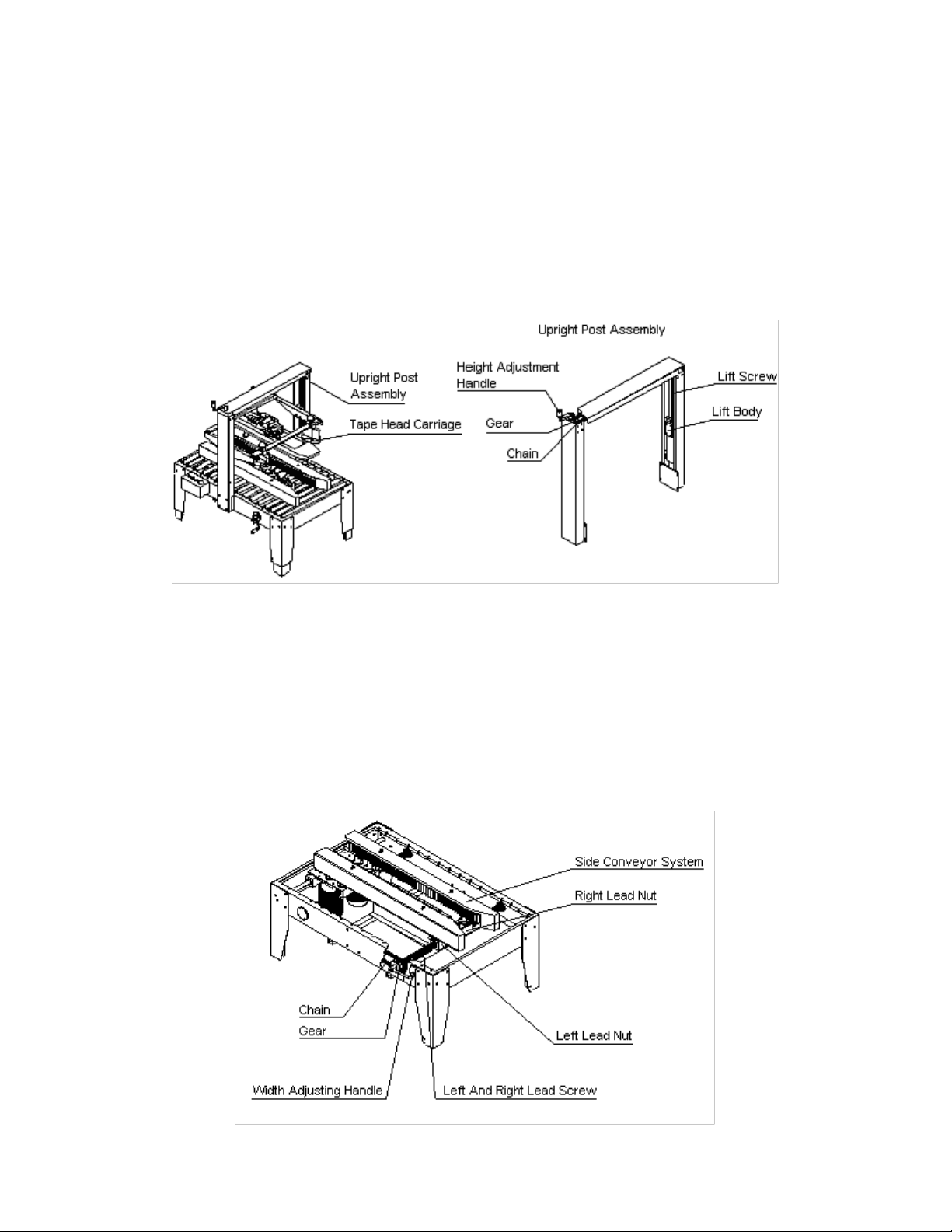

2. Adjust horizontal and vertical guides to accommodate cartons to be sealed

3. Press the button labeled ‘Start’

4. Verify belt movement direction

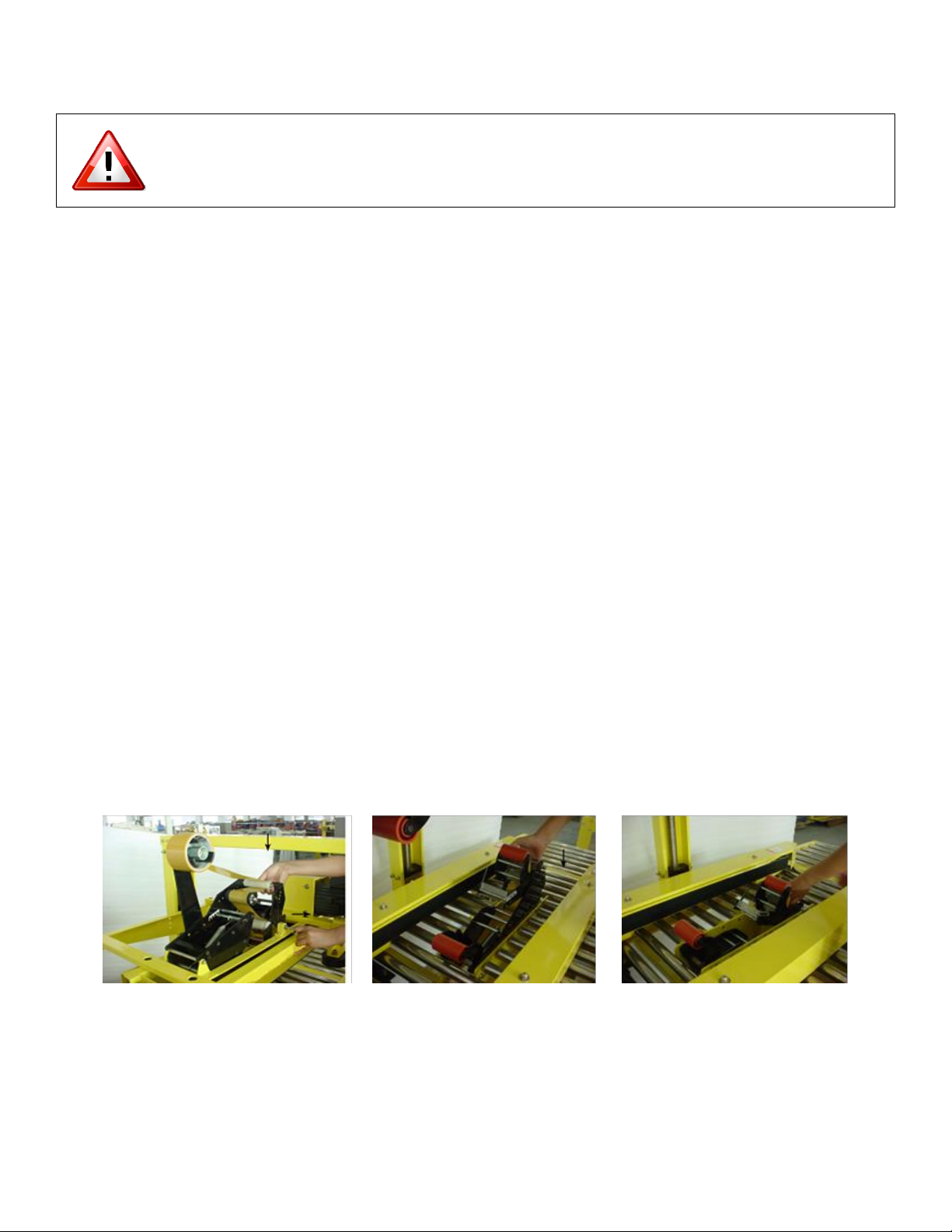

5. Place carton to be sealed into the feed side of the machine

a. Cartons must be placed in the center of the roller table for proper feed through the

machine

After operating the machine for two to five minutes, check the following

1. Horizontal guide adjustment lever is firmly in place and belts do not have excess slack

a. Belt deviation (slack) should be checked once every ten days

b. Adjust belt tension as needed

2. Vertical guide adjustment lever is firmly in place

3. Verify that tape is being dispensed in a consistent manner that ensures a smooth application

onto the carton being fed through the machine.

TURN OFF MACHINE AND DISCONNECT IT FROM THE POWER

SOURCE PRIOR TO PERFORMING ANY MAINTENANCE OR SERVICE

4.2 Adjustable Work Height

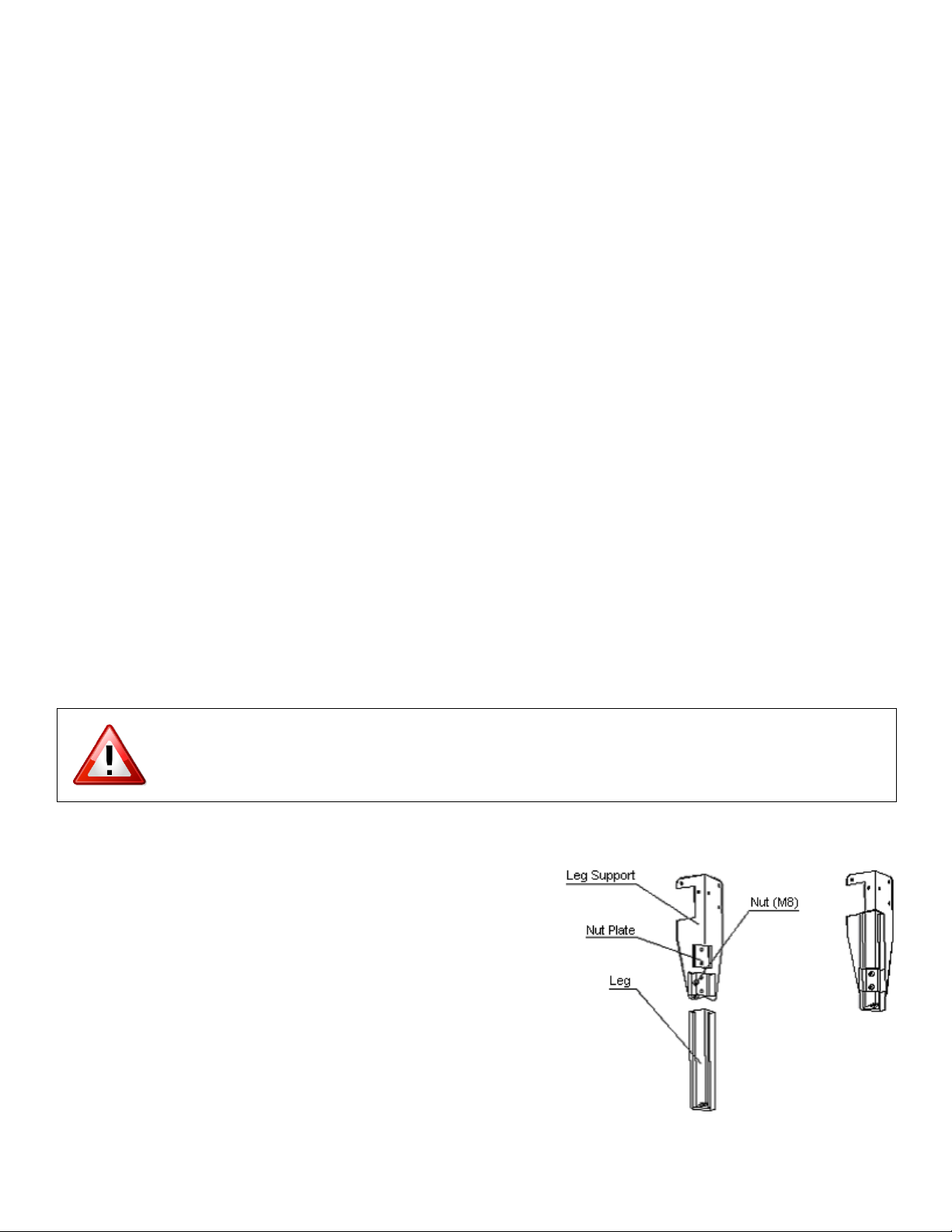

Put the nut plate into the leg support according to the

figure.

Then loosely connect the fastening piece and the nut plate

with the socket head cap screws. Insert the leg between the

leg support and nut plate. The leg can now be adjusted up

and down as desired. Tighten the screws.

The working height should be set such that the operator is

able to comfortably reach the roller table while maintaining

approximately 4in (100mm) of distance from the machine.