- 4 -

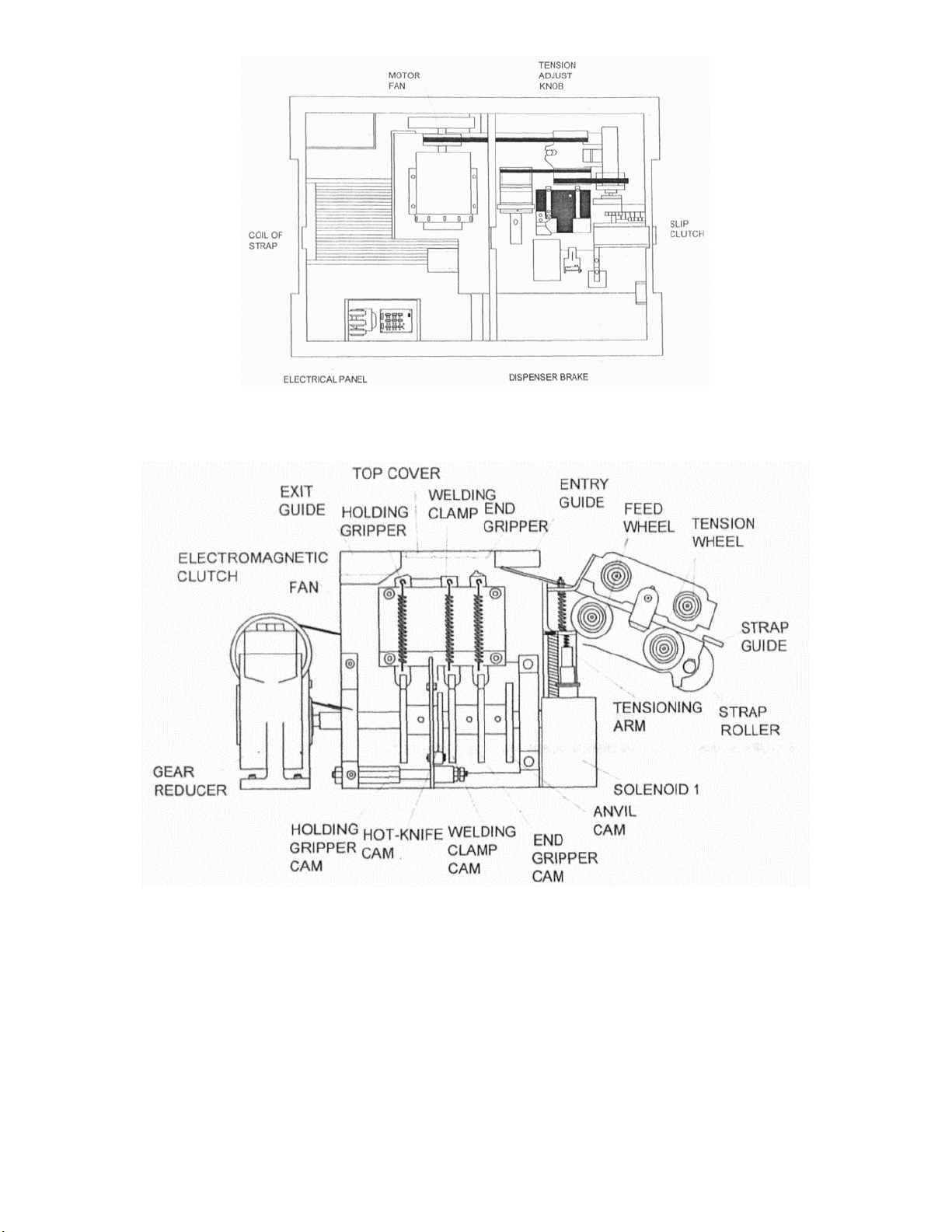

2. Components

Strap Dispenser

The strap dispenser supplies strapping material to the strapping head. It is located inside the cabinet

on the lower left-hand side. A friction brake is provided to limit over-run of strap.

1. Grip – The grip holds the lead end of the strap beneath the anvil while the remainder of the

strap is being tensioned around the package.

2. Strap Feed & Tension – Both feed and tension are achieved by two sets of gear rollers powered

by an electric motor by means of a drive belt and slip clutch system.

a. An operator controlled adjustable timer controls the duration of strap feed. When the

set time for feeding is up, the timer stops feeding strap. If additional feed is required

beyond that determined by the timer setting, jog feed will be facilitated by pushing the

“Jog” feed button on the operator control panel.

3. Welding & Cut-Off – Welding of the strap ends and cutting of the strap supply are facilitated in

this process.

4. Package Release – After a short weld-cool period (necessary to avoid welded ends from

separating), the package is released.

Functions 1, 3, and 4 are driven by a cam shaft coupled to the drive system by means of an

electromagnetic clutch which turns on full revolution per cycle.

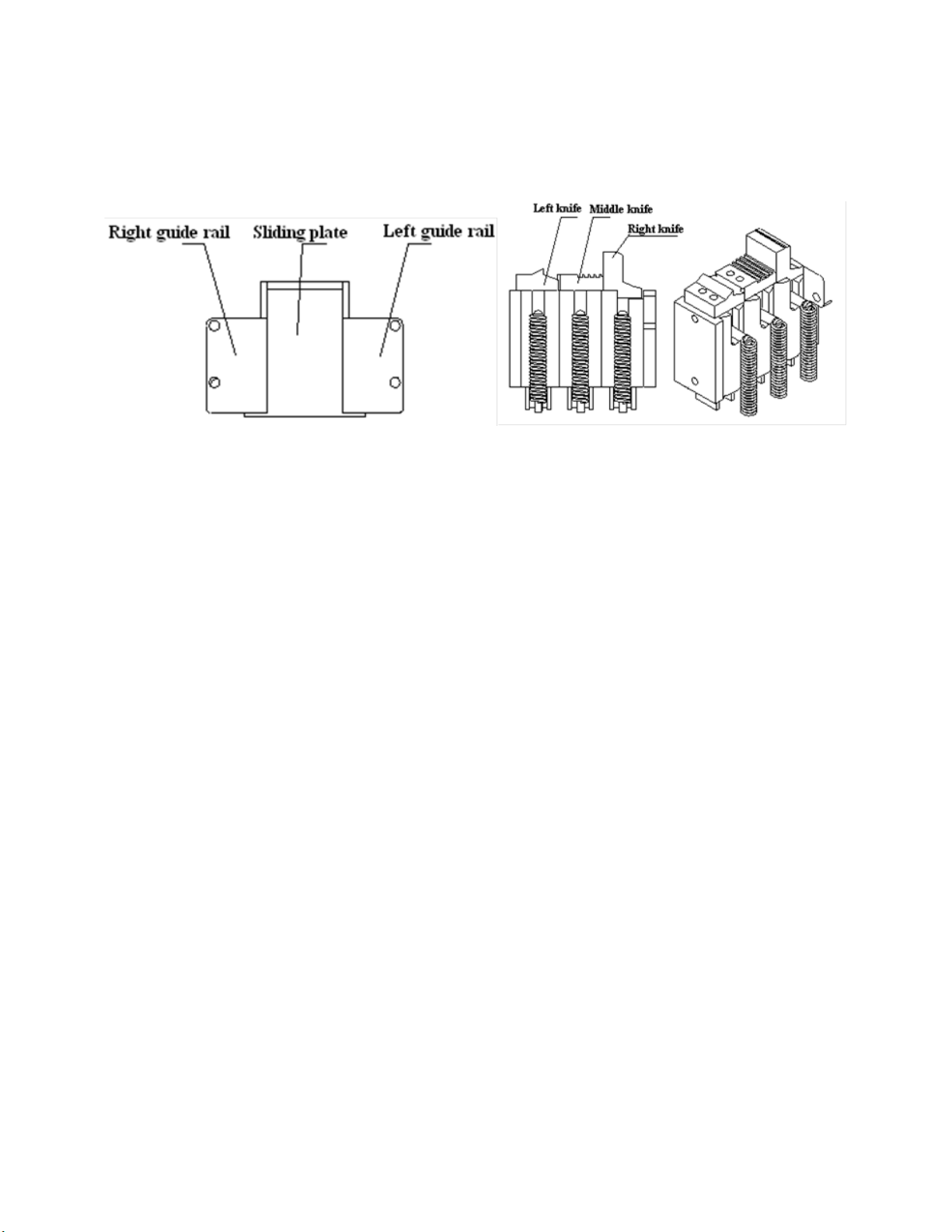

Hot Knife

The “Hot Knife” is centrally located at the front of the strapping head. Movement of the knife is

controlled by a cam.

Electrical System

An all new electrical system using solid state technology supplies continual power to the components

within the machine. Using simple to insert circuit boards, the Eagle 100 provides for safe and relatively

maintenance-free operation.

Operator Controls

The electrical control panel consists of the following control switches/buttons; Main Power, Feed

Length Timer, Reset Switch, Feed Length Switch