Click Pack manual 2019-3

03 Use

Filling

The temperature of the content cannot exceed 70°C. The content

has to cool down to 30°C before the container can be closed. The

drum can be closed according to instruction 1.

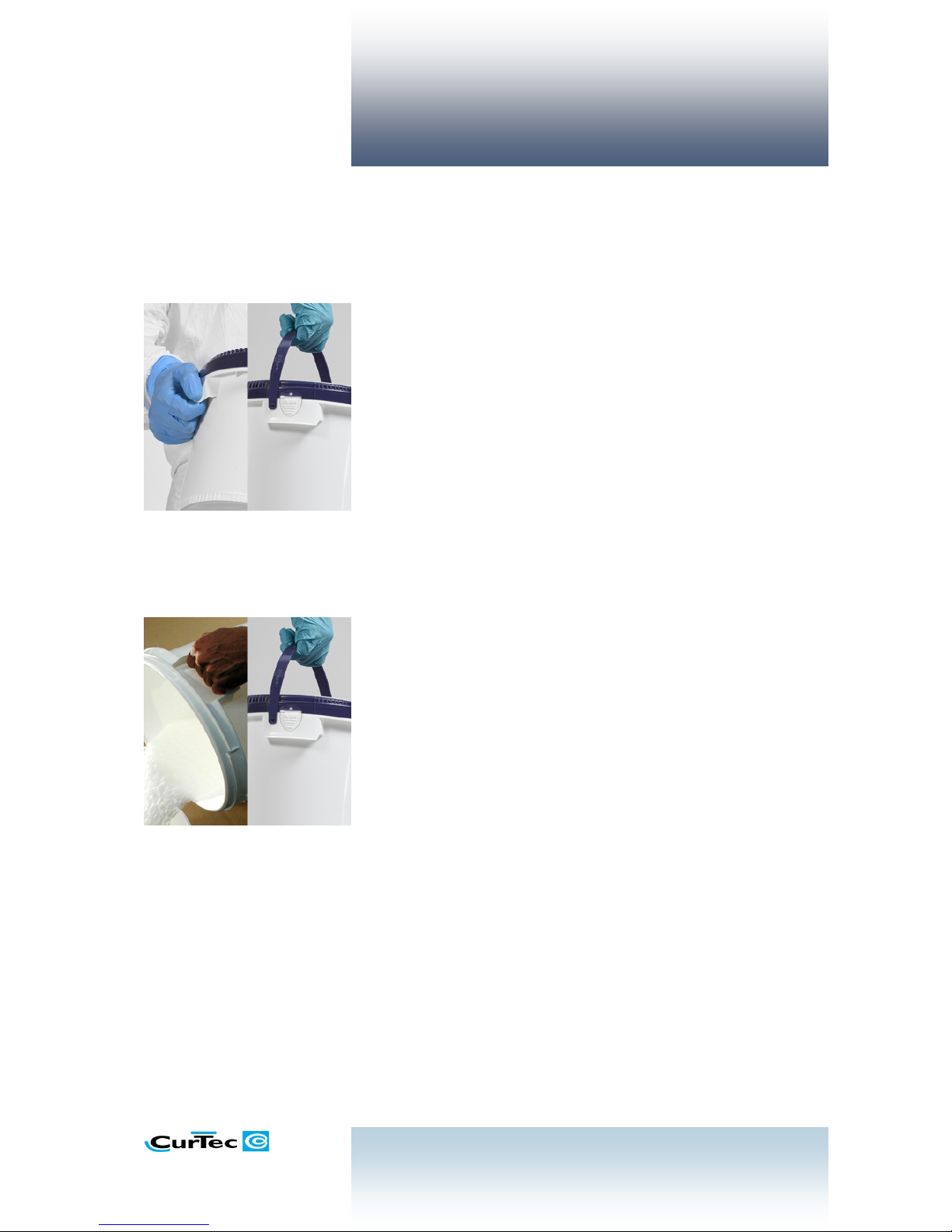

Lifting

A Click Pack can be easily lifted and moved both mechanically and

manually. Use the handgrips on the container or the (optional)

handle.

Charging the handle

The handle has been designed for manual handling only. They are

are not suitable for mechnical handling, such as lifting a Click Pack

with a hoist. The maximum charge on a handle is:

-6 kg > 4406

-30 kg > 4410/15/20, 4515/20/25

These weights match the UN markings and have been validated.

Attention! Please consider the HSE regulations regarding weight

and frequency restrictions for lifting

Emptying

Open the container following instruction no. 2. Use the rim, the

handle or the pouring grip and the base to tip the container and

pour out the contents.

Freezing

Click Pack is made of plastic which is resistant to a minimum

temperature of -18°C. As of -5°C, shock load on the containers

should be avoided.

Attention! The volume of containers filled with water-based

contents can increase by 10%. The chances that containers will

distort is real and it will reduce the stability of a container stack on

a pallet. Please maintain a maximum filling level of 90% and test

the stability of a pallet stacking.