STOROpack AIRmove2 User manual

AIRmove² - Perfect Protective Packaging

User Manual

AIRmove2- Perfect Protective Packaging 1

AIRmove2- Perfect Protective Packaging 2

Copyright © STOROpack

All rights reserved.

Dear customer,

Thank you for choosing our AIRmove2 . For optimal use, please familiarize yourself with the contents of this

user manual and pay special attention to our instructions concerning safe operation of the device.

General information:

Unless expressly authorized, reproduction, copy or translation of this device, its accessories or the technical

documentation without previous approval of STOROpack GmbH + Co. KG is strictly forbidden.

STOROpack GmbH + Co. KG cannot be held responsible for any involuntary errors in this manual. Please,

don’t hesitate to forward us any proposals to improve this user manual.

Asia-Pacific: + 852 3421 2392

Europe: + 49 800 78 67 67 22

North America: +1 800 827 7225

South America: +55 11 5677 4699

Email : packaging@STOROpack.com

www.STOROpack.com

*** Conditions of use ***

This device can only be used to manufacture packaging material

made of plastic film. The user of this device is committed to follow all

instructions in this guide book. The user is also entirely responsible for all

safety precautions of this device.

In case of modification or disregard of this instruction we will cancel all

warranty conditions and the manufacturer’s liability.

STOROpack GmbH + Co. KG cannot be held responsible for any damages caused by

improper use of the machine or void air cushions.

AIRmove2- Perfect Protective Packaging 3

Contents

1. Introduction.......................................................................................................................................... 4

2. Safety Instructions .............................................................................................................................. 4

3. Declaration of Conformity................................................................................................................... 6

4. Description of AIRmove2..................................................................................................................... 6

4.1 Technical Specifications.................................................................................................................... 6

5. Box Contents ....................................................................................................................................... 7

6. Machine Overview ............................................................................................................................... 7

6.1 Keypad Functions ............................................................................................................................. 8

7. Setting Up the Device for Use ............................................................................................................ 8

7.1 Assembly of the Film Roll Holder ...................................................................................................... 8

7.2 Film Roll Holder Positions for Smooth Film Flow .............................................................................. 8

7.3 Display and Keypad Location............................................................................................................ 9

7.4 Fitting a New Film Roll .................................................................................................................... 10

7.5 Power Switch and Connections....................................................................................................... 11

7.6 First Parameter Set-Up ................................................................................................................... 11

8. Menu Structure .................................................................................................................................. 12

8.1 Start Film production ....................................................................................................................... 12

8.2 How to Adjust Air Settings............................................................................................................... 13

8.3 How to Adjust Sealing Temperature................................................................................................ 13

8.4 How to Adjust Runtime.................................................................................................................... 14

8.5 How to Use External Input Devices................................................................................................. 14

8.6 Extern IN Mode 0 ............................................................................................................................ 14

8.7 External Input Mode 1 ..................................................................................................................... 15

8.8 External Input Mode 2 ..................................................................................................................... 15

8.9 Mode 2 Stop Delay.......................................................................................................................... 16

8.10 How to Change Film Type............................................................................................................... 16

8.11 Factory settings............................................................................................................................... 17

9. External Start and Stop Devices....................................................................................................... 18

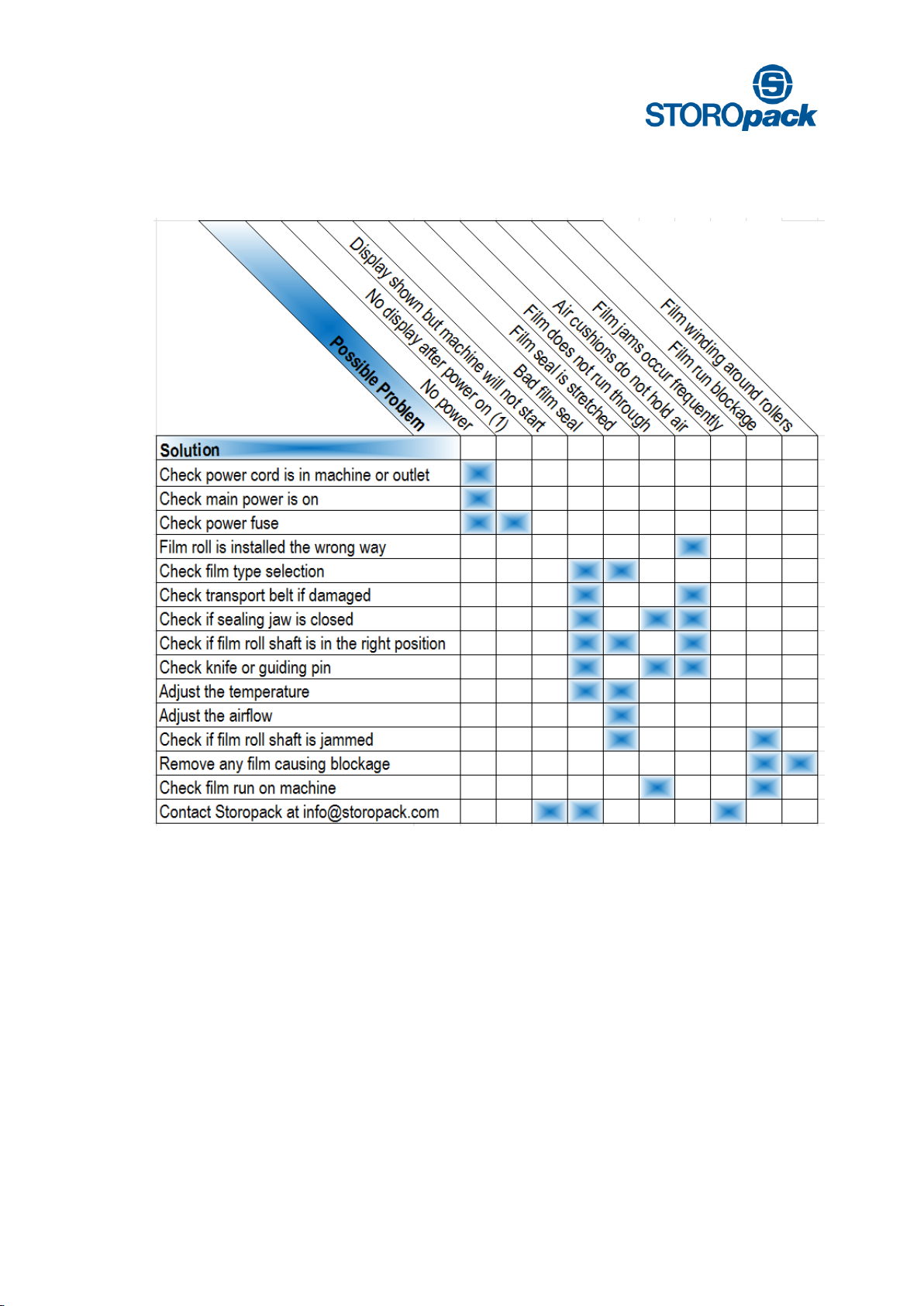

10. Troubleshooting AIRmove²............................................................................................................... 19

11. How to Change Wear Parts............................................................................................................... 20

AIRmove2- Perfect Protective Packaging 4

1. Introduction

This user manual has been compiled by STOROpack with all due care to enable safe and fault-free

production of air pillows with the AIRmove2machine. Before operating AIRmove2, familiarize yourself with

the contents of this user manual to guarantee safe operation. When the AIRmove2is in operation, the user

must ensure that nobody will be bodily damaged due to unauthorized intervention into the production

process.

2. Safety Instructions

To guarantee personal safety, the following instructions must be carefully observed:

1.) Work Area

a. Keep the work area clean and well lit. Cluttered and dark areas invite accidents.

b. Place the AIRmove2machine on a flat, dry surface.

c. Do not operate AIRmove2in explosive atmospheres, such as in the presence of

flammable liquids, gases or dust. Do not place flammable materials in, on or around the

machine.

2) Electrical Safety

a. The power plug must match the outlet and the outlet must be appropriately grounded. Do

not modify the plug in any way. Do not use adapter plugs or extension cords.

b. Do not expose the AIRmove2machine to wet conditions. As with any piece of electrical

equipment, operating the machine when wet will increase the risk of electrical shock.

c. Do not abuse the power cord. Never use the cord for carrying, pulling or unplugging the

AIRmove2machine. Keep cord away from: heat, oil, sharp edges or moving parts.

Damaged or entangled cords increase the risk of electrical shock.

d. For installation and maintenance work, the machine must always be turned off by the main

switch and be disconnected from the main power connection. The machine operator must

avoid any contact with the electrical parts.

e. All safety and protective measures and facilities must have been applied and be

maintained in accordance with IEC instructions (International Electrotechnical

Commission).

f. The machine instructions are provided by STOROpack’s own staff or staff delegated by

STOROpack. STOROpack’s liability under IEC regulations no longer applies if changes or

additions are made to the machine without STOROpack’s permission.

AIRmove2- Perfect Protective Packaging 5

3) Personal Safety

a. Stay alert, watch what you are doing and use common sense when operating the

AIRmove². Do not use AIRmove² when you are tired or under the influence of drugs,

alcohol or medication.

b. Prevent accidental starting. Ensure the switch is in the off position before plugging in.

c. Avoid loose clothing, jewellery, long hair, etc. from contact between the drive wheels. Do

not place anything between the drive wheels other than STOROpack film. This includes

paper, metal, tools, etc.

d. There is an extremely sharp knife blade under the Air injector assembly. As this is a part

that may wear over time and must be replaced, great care must be taken when removing

and handling the blade. Strictly adhere to the blade replacement instructions in the user

manual.

e. The film is sealed by using a heated wire which is located under a Teflon belt. (below the

blue protective covers). This wire gets very hot and may cause burns if touched. During

normal operation the wire is not exposed, but care must be taken when replacing film or

replacing the Teflon belt. Switch the machine off and allow the wire 2-3 minutes to cool

down before performing any operation exposing the wire. Instructions for replacement can

be found in the user manual.

4) AIRmove2Use and Care

a. Switch the machine off and disconnect the plug from the power source before performing

any operation to the AIRmove2machine. This includes replacing film, cleaning or

maintenance.

b. DO NOT lift using the power cord.

c. The AIRmove2machine requires periodic cleaning –more often if operated in dirty or

dusty conditions. Check for misalignment or binding of moving parts, broken parts and

any other condition that may affect the operation. Do not operate a damaged machine.

d. This system was designed for processing a specific film type. In order to guarantee

smooth function, only original STOROpack’s consumables should be used.

e. In emergency situations, set the main switch to “0”. The machine will be switched off

within a few seconds (when indicator is turned off completely). After eliminating the

emergency situation or fault, the machine can be switched on again according to the user

manual.

f. The manufacturer is not liable for any modifications of the machine which are made

without written approval from STOROpack.

AIRmove2- Perfect Protective Packaging 6

3. Declaration of Conformity

Declaration of Conformity

We declare under our sole responsibility that the product described as AIRmove2machine is in conformity

with the following standards or standardization documents: 2006/42/EEC, amended by 91/368/EEC,

93/44/EEC and 93/68/EEC.

Standards; EN ISO 12100:2010 Safety of machinery.

M. Korten

Vice president Ideepak b.v.

19-09-2016, Ideepak b.v. Industrieweg 24, Stramproy –Holland 6039 AP

4. Description of AIRmove2

AIRmove2converts pre-perforated tubular films of 200 mm (8”) and 400 mm (16”) width into air cushions.

This chapter explains the technical data, the setup and operation of AIRmove2.

4.1 Technical Specifications

Voltage

95 –250 VAC; 50/60 Hz

Power consumption (max.)

97 W

Power consumption

76 W

Power consumption (stand-by mode)

6,2 W

Recommended main fuse

3.15 AMP

Dimensions

370 mm x 364 mm “ | 14 2/3“ x 14 1/3“

Height

329,5 mm | 13“

Transport speed

Max. 10 m/min. | ~33 lin.feet./min

Weight

7.1 kg | 15.65 lbs.

Sound pressure level

52 db

AIRmove2- Perfect Protective Packaging 7

5. Box Contents

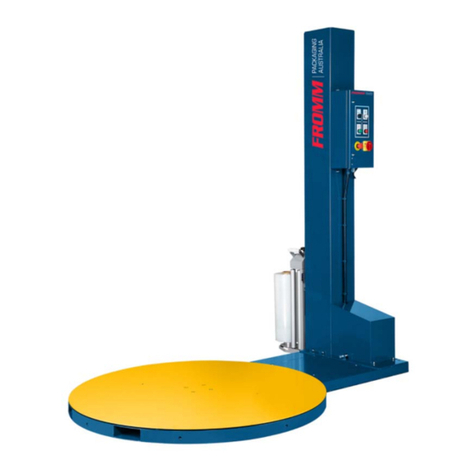

6. Machine Overview

The AIRmove2 consists of the following components:

1

The film roll holder of the AIRmove2will be delivered disassembled.

USB-B connector

Control panel

Unlock knob

Main power

switch and

power socket

Film roll holder

Sealing unit

Injector

External input

connection

AIRmove2- Perfect Protective Packaging 8

6.1 Keypad Functions

7. Setting Up the Device for Use

7.1 Assembly of the Film Roll Holder

Remove the AIRmove2machine and the blue film roll shaft from the box. Insert the metal part into hole on

the front side of the machine.

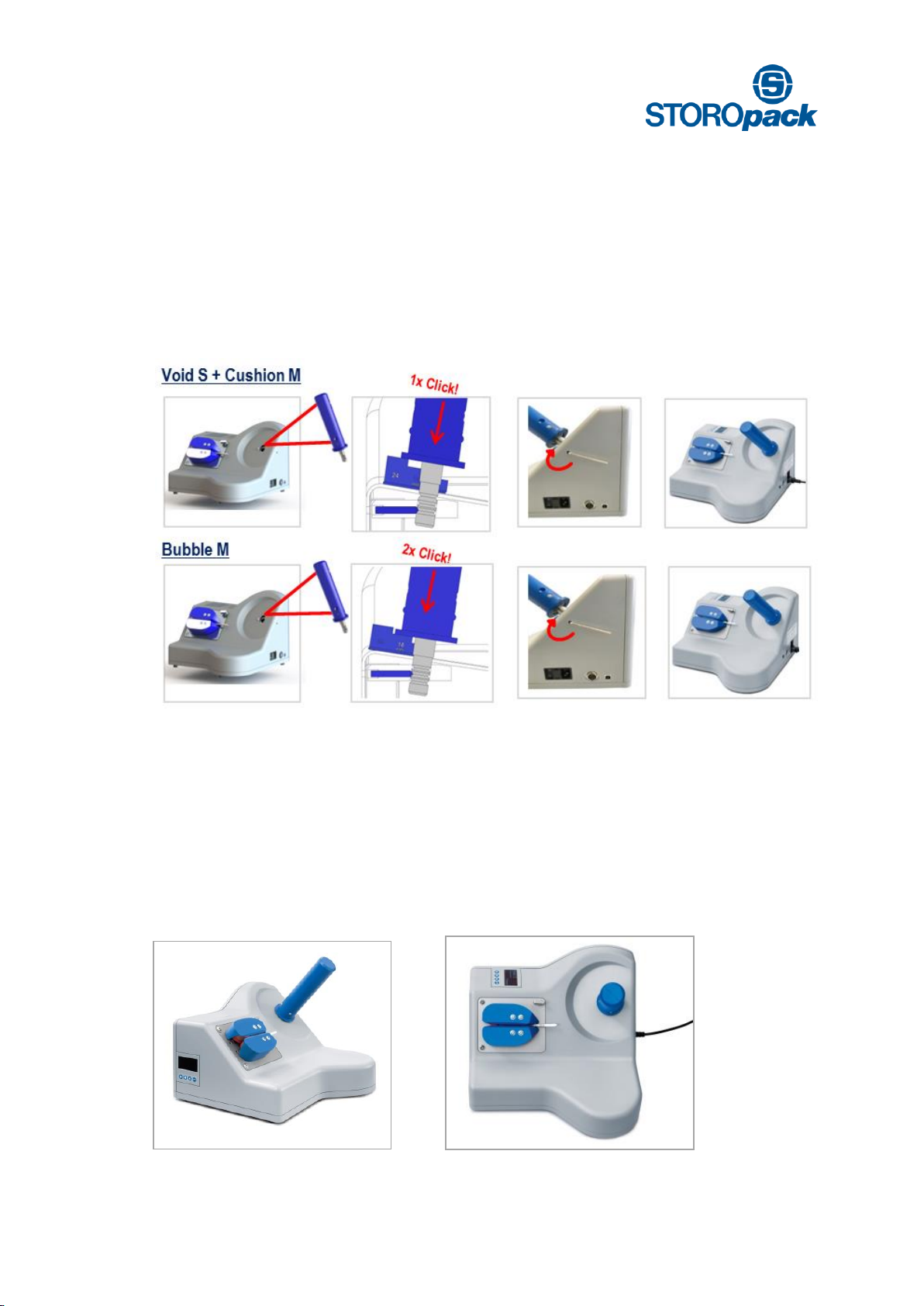

7.2 Film Roll Holder Positions for Smooth Film Flow

Airmove2films are available in three different options:

Film description

Air Pillow dimensions

Length

Void S, 25 µ

200 mm x 120 mm

350 m

Bubble M, 25 µ

400 mm x 160 mm (29b)

350 m

Cushion M, 25 µ

400 mm x 250 mm (16p)

350 m

Film description

US Air Pillow dimensions

Length

Void S, 1.0 mil

8” x 5”

1150’

Bubble M, 1.0 mil

16” x 9.76”

1150’

Cushion M, 1.0 mil

16”x 6”

1150’

Position

Name

Function

Start/Stop Button

Starts or stops the machine

Arrow up

Increases the value

Scrolls up

Arrow down

Decreases the value

Scrolls down

Enter Button

Confirms

Enter menu

Enter menu item

AIRmove2- Perfect Protective Packaging 9

Therefore you must choose between two film roll holder positions. By loosening the screw in the cover on

the right side of the machine, you can adjust the film roll holder.

You will hear and feel a “click” when the shaft arrives at each position. Alternatively you can use the spacing

gauge to find the right setting.

Cushion M + Void S = 24 mm (15/16”)

Bubble M = 18 mm (11/16”)

The screw needs to be tightened again afterwards.

7.3 Display and Keypad Location

With your Airmove2machine there are two possible display positions. To change keypad position, first make

sure you disconnect from the power supply.

Remove the four screws in the cover of the machine with the provided allen key in the box. Insert the display

into the desired position (see picture 1 and 2). Then replace the cover and tighten the four

screws. Reconnect to the power supply to continue.

1.) Keypad front position 2.) Keypad top position

AIRmove2- Perfect Protective Packaging 10

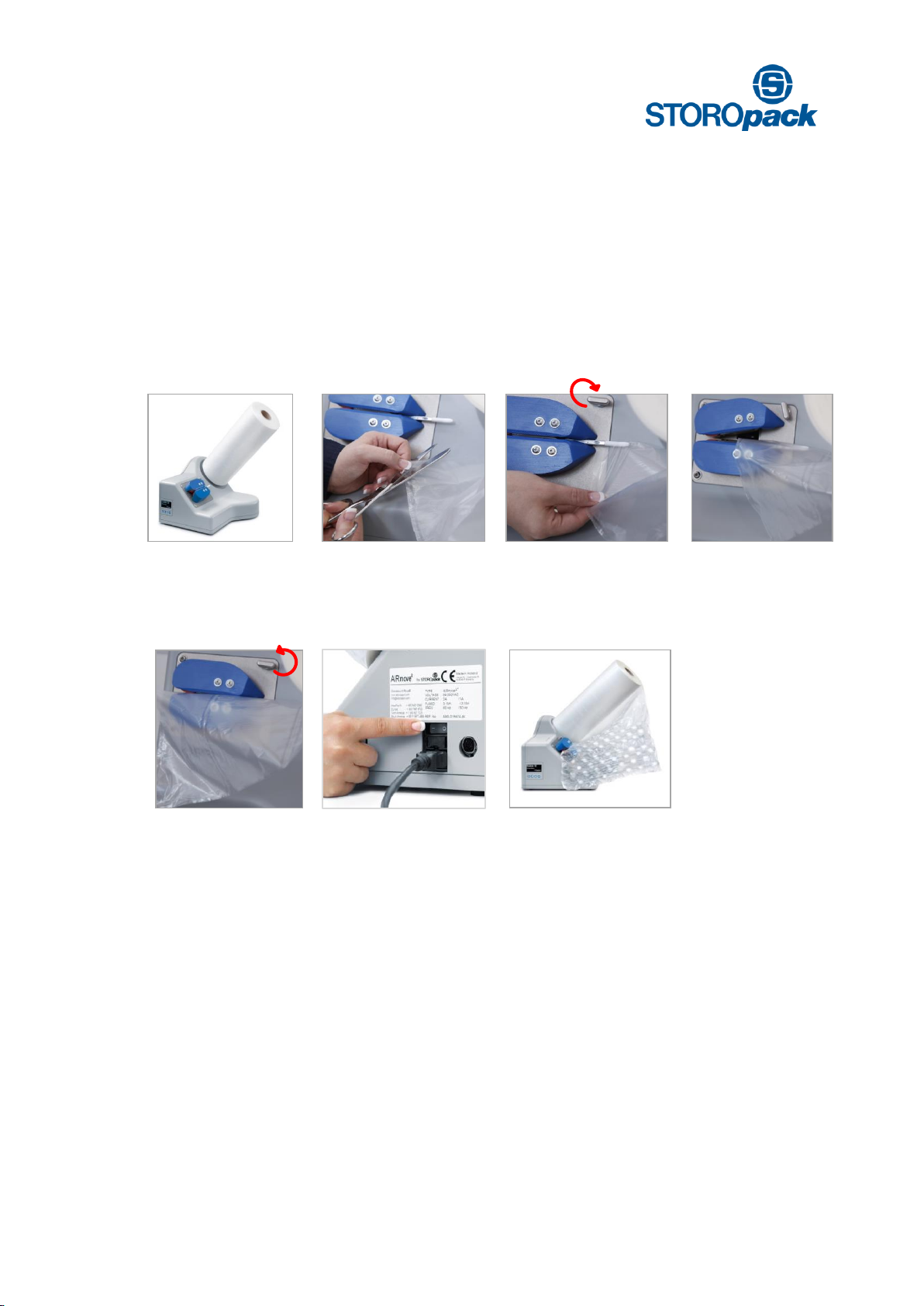

7.4 Fitting a New Film Roll

Make sure the machine is not running while changing rolls!

If there is an empty roll on the machine, remove it from the film roll holder. To fit a new film roll, please

proceed as follows: Slide the new film roll onto the film roll holder. Ensure that the film is oriented to unwind

from the underside of the roll.

The film roll has continuous cross perforations and a non-continuous cross-seal. There is a gap between the

edge of the film and the perforations.

Cut a little corner off the film gap. Slide the gap over the white injector. Turn the unlock knob clockwise to

unlock the top sealing unit. Slide the film between the sealing units as far as possible until you feel

resistance.

Turn unlock knob counter clockwise to lock the top sealing unit. Always make sure that the knob is locked to

ensure a good seal quality!

AIRmove2- Perfect Protective Packaging 11

7.5 Power Switch and Connections

After checking the power supply, the system can be switched on. The main switch is on position “I”.

Power switch, fuse and

main power entry

Circular DIN connector,

8 pins

USB B type connector

7.6 First Parameter Set-Up

To ensure the best quality Air pillows, Airmove2operates using three different film type menus. After fitting a

film roll the appropriate film type menu must be chosen. The Start screen will appear after switching the

machine on:

Machine off Power switch on first time Start display

Power switch [ 0] Power switch on [ 1] Display Software

display off first display (2 sec) Machine Software

Machine Number

AIRmove2- Perfect Protective Packaging 12

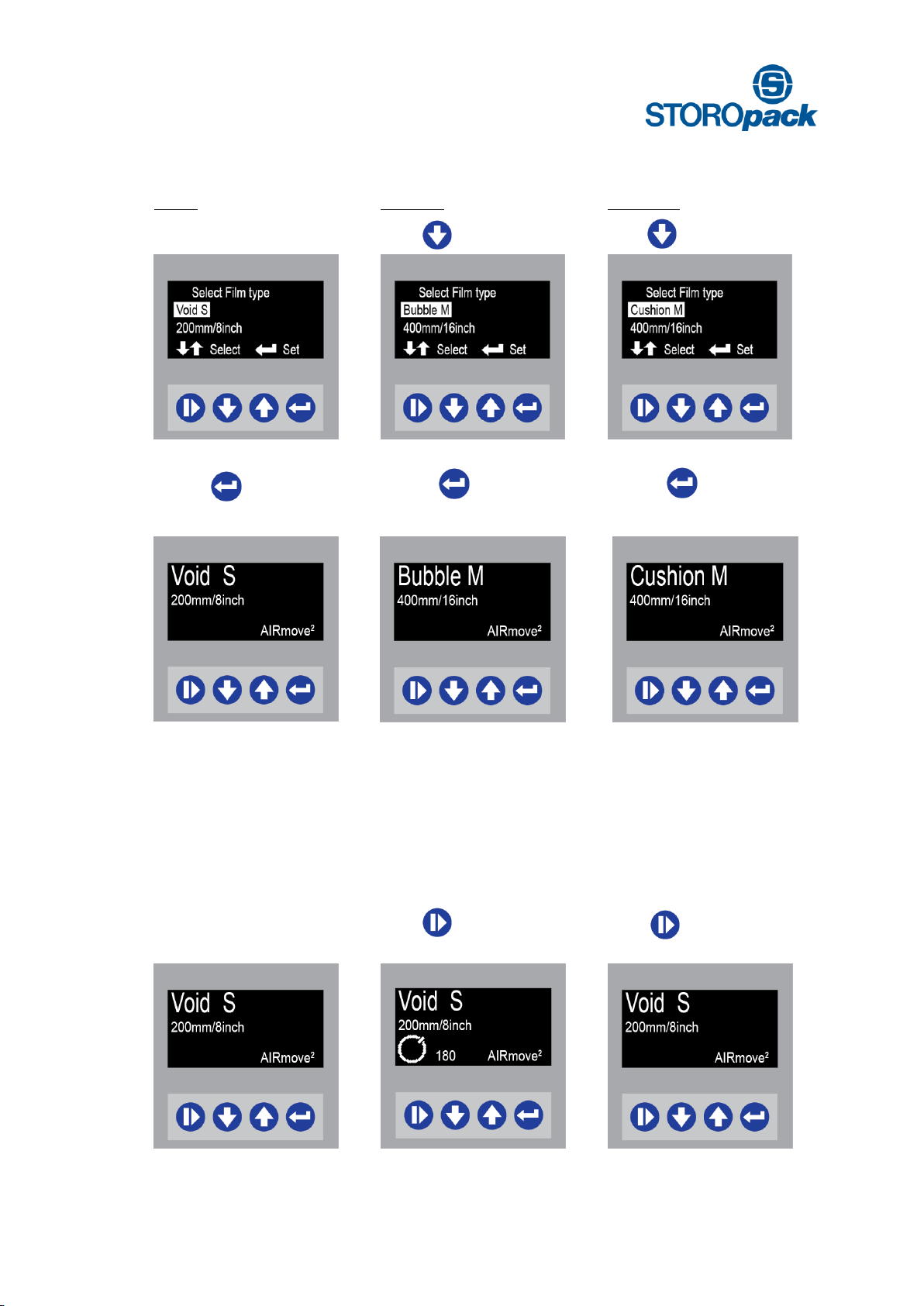

There are three different film type menus available when you turn on the machine the first time.

Void S

Bubble M

Cushion M

Void S is already highlighted

Press for Bubble M

Press 2 x for Cushion M

press to confirm choice for

Void S as the film to process

press to confirm choice for

Bubble M as the film to process

press to confirm choice for

Cushion M as the film to process

8. Menu Structure

8.1 Start Film production

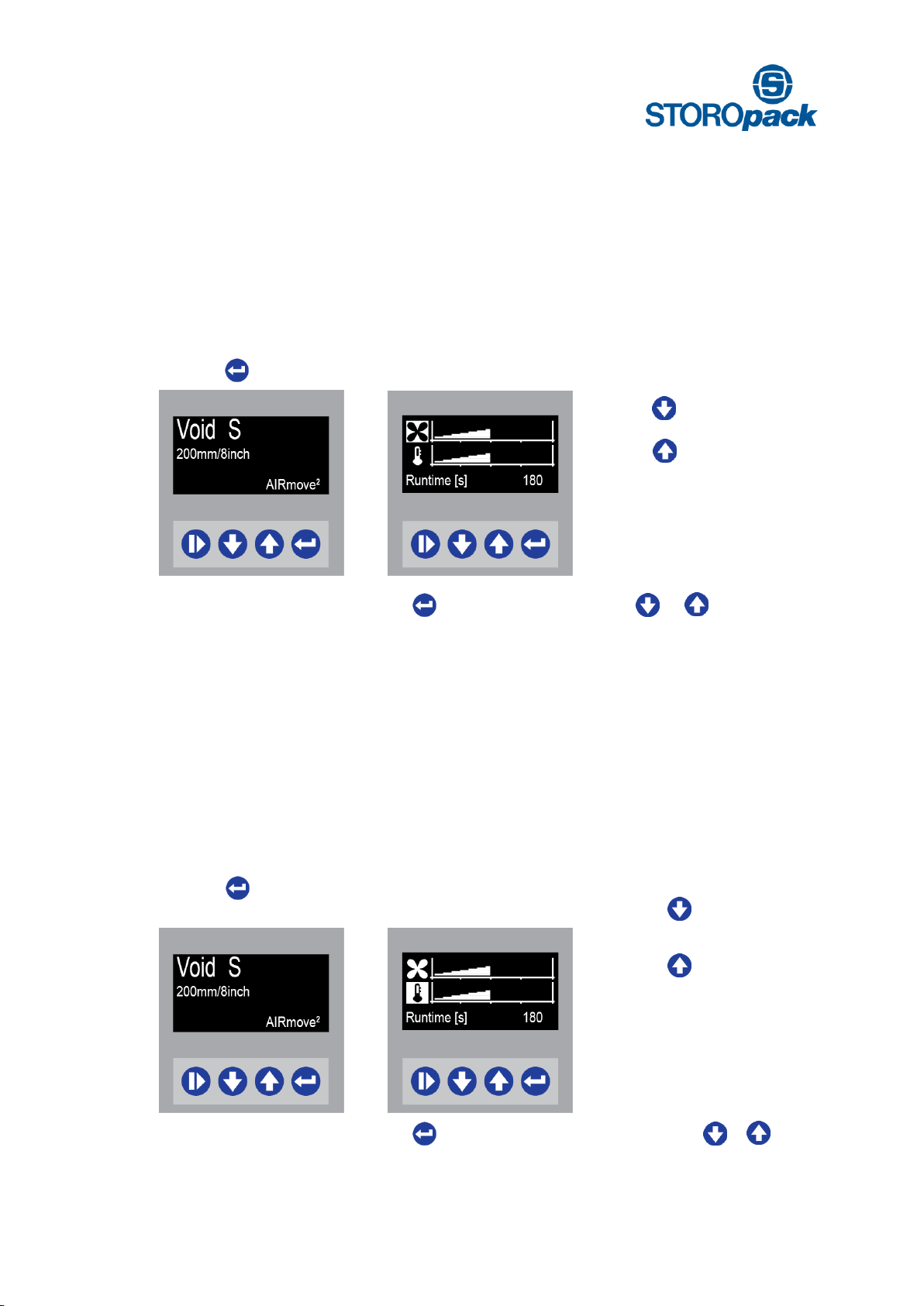

Once a menu is selected with its pre-set parameters the machine is ready to operate. Every menu follows

the same steps:

Machine is ready to start Void S

film production

Press to start Void S film

production

Press again to stop

Void S film production

AIRmove2- Perfect Protective Packaging 13

8.2 How to Adjust Air Settings

The chosen AIRmove² film type menus automatically run on the correct air and temperature settings. You do

not need to adjust machine settings manually, but if the automatic settings are not optimal for some reason,

the keypad allows you to change the following settings:

Display Void S

ready to start

Press 1 x for air settings

Display Air Settings

Amount of air is now adjustable

Press to decrease air

Press to increase air

Even while the machine is running press to change air settings by using or . While the machine

is running the Runtime sign will not show up.

8.3 How to Adjust Sealing Temperature

The chosen AIRmove² film type menus automatically run on the correct air and temperature settings. You do

not need to adjust machine settings manually, but if the automatic settings are not optimal for some reason,

the keypad allows you to change the following settings:

Display Void S

ready to start

Press 2 x for temperature

settings

Display Temperature Settings

Sealing temperature is now

adjustable

Press to decrease

temperature

Press to increase

temperature

Even while the machine is running press to change temperature settings by using or .

While the machine is running the Runtime sign will not show up.

AIRmove2- Perfect Protective Packaging 14

8.4 How to Adjust Runtime

To produce a desired amount of air pillows, a specific Runtime can be set. Runtime is indicated in seconds

and its factory settings are 180 sec. The set Runtime will run down to “0” and production will stop.

Display Void S

Press 3 x to get to the

Runtime Menu

Change Runtime settings

Minimum setting is 1 sec

Maximum setting is 2400 sec.

Press to decrease runtime

Press to increase runtime

8.5 How to Use External Input Devices

Use the Circular DIN connector to attach the external input device.

External start and stop devices enable an ergonomic operation of the machine. A foot pedal allows hand-

free production of air cushions, a push-button allows easy operation when the machine is out of reach. The

Extern IN mode enables you to use an external device, which will be connected to the machine. Following

options are available for the Extern In Mode:

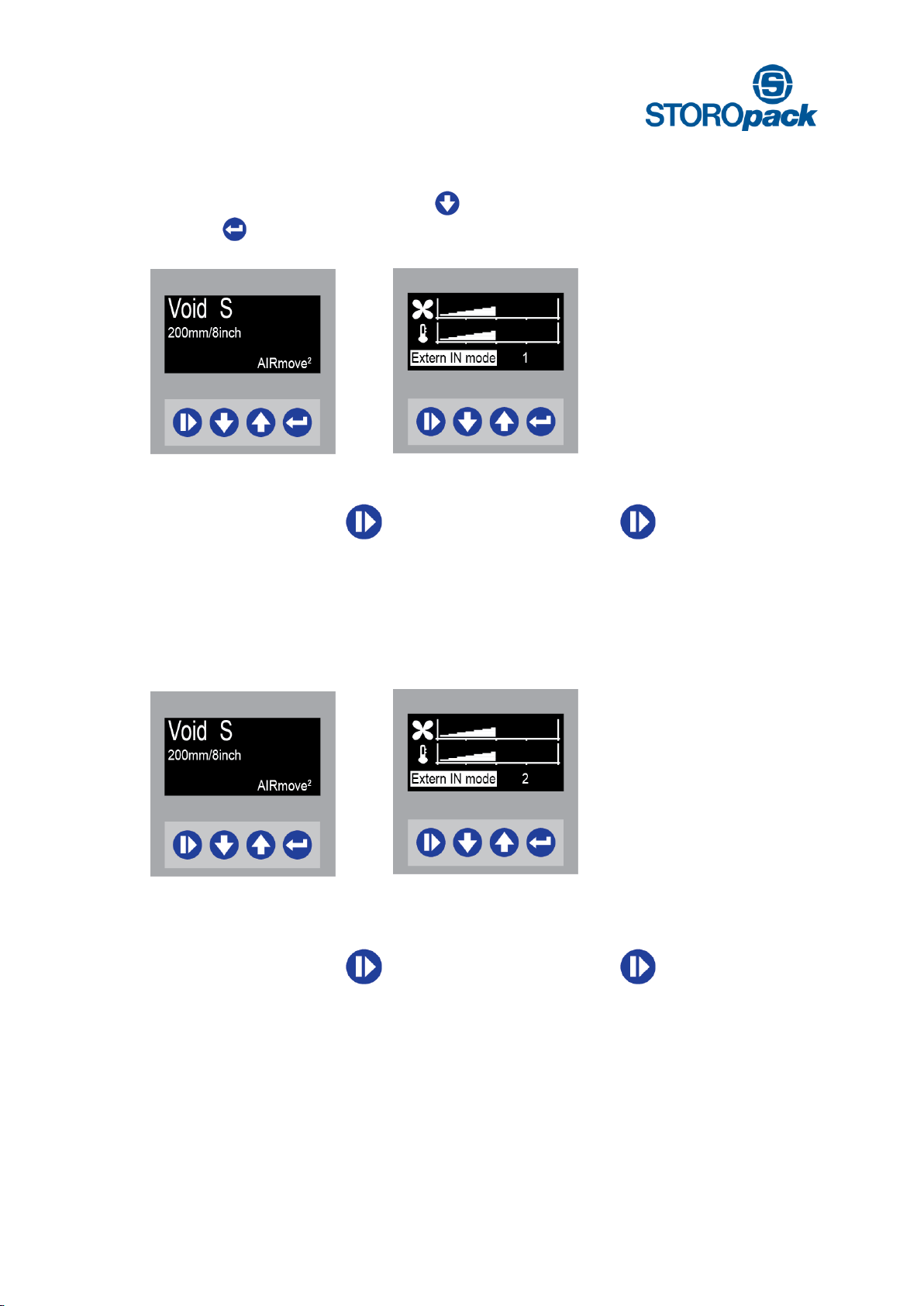

8.6 Extern IN Mode 0

Display Void S

Ready to start

Press 4 x to change

Extern IN mode

Extern IN mode

Possible options [ 0 ], [ 1 ]

and [ 2 ].

Press or to adjust the

desired Extern IN mode

You can choose between manual and device control options (foot pedal or push button).

AManually Start: push Stop: push

BExt. Device Start: press down and release pedal Stop: press down and release pedal

AIRmove2- Perfect Protective Packaging 15

8.7 External Input Mode 1

Ready to start

Press 4 x to change

Extern IN mode

Press to set

Extern IN Mode 1

You can choose between manual and device control options (foot pedal or hand-buzzer).

AManually Start: push Stop: push

BExt. Device Start: press down pedal Stop: release pedal

8.8 External Input Mode 2

External input mode on [ 2 ] the machine works as using mode [ 1 ] but has a stop delay option.

You can choose between manual and device control options (foot pedal or push button).

AManually Start: push Stop: push

BExt. Device Start: press down pedal Stop: release pedal

(stop, if stop delay time has gone by)

With External input mode on 2 , a stop delay is set. Ex-works settings for Extern stop delay are 7 sec.

AIRmove2- Perfect Protective Packaging 16

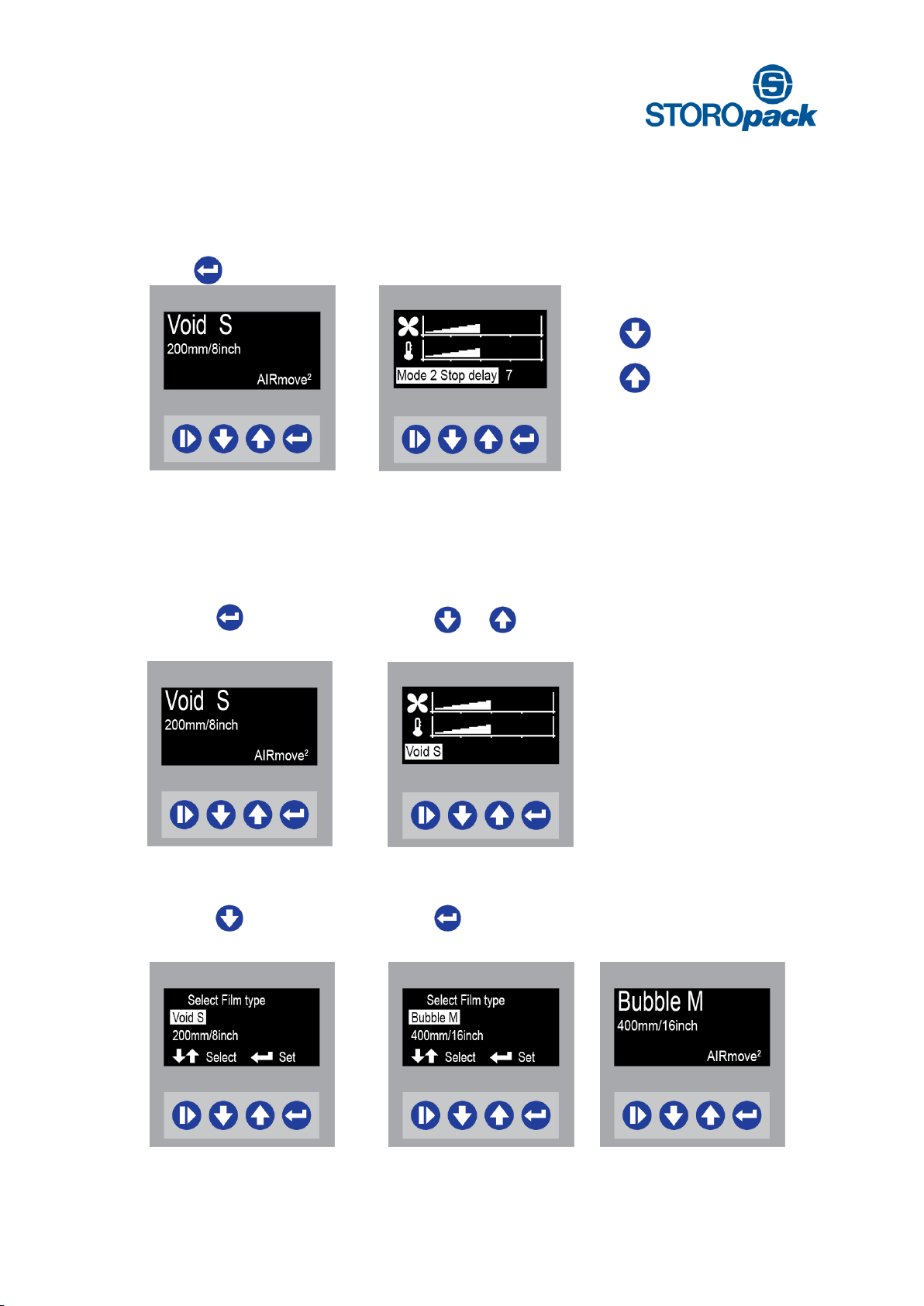

8.9 Mode 2 Stop Delay

Display Void S

ready to start

Press 5 x to change stop delay

Change Mode 2 Stop Delay

Stop delay is indicated in

seconds

Press to decrease stop delay

Press to increase stop delay

8.10 How to Change Film Type

Changing the menu to a new film type when loading a different kind of film.

Display Void S

Press 6 x until film type

shows up

Press or to change

the film type

Selection Void S

Press 1 x to change to

Bubble M

Selection Bubble M

Press and

Bubble M will be set

Bubble M

AIRmove2- Perfect Protective Packaging 17

Selection Void S

Press 2 x to change to

Cushion M

Selection Cushion M

Press and

Cushion M will be set

Cushion M

8.11 Factory settings

The ex-works setting enables resetting all choices, parameters, adjustments and changes back to the

factory settings.

Machine off

Power switch [ 0]

display off

Power switch on

Power switch on [ 1]

Press +

and hold while switching on the

machine.

Release the buttons + when

the display runs

All settings have been reset, proceed with section “First-parameter Set-up” again to choose a film type.

AIRmove2- Perfect Protective Packaging 18

9. External Start and Stop Devices

External start and stop devices enable an ergonomic operation of the machine. A foot pedal allows hand-

free production of air cushions, a push button allows easy operation when the machine is out of reach.

Foot controls allow the worker to activate the film production

manually by pressing down on a foot switch or pedal, leaving

the hands free during the production process.

The Extern IN mode of the AIRmove² is for remote control

with an external device, foot pedal or on/off knob, connected

to the machine.

AIRmove² can also be equipped with a push button which

enables easy use when the machine is out of reach.

AIRmove2- Perfect Protective Packaging 19

10. Troubleshooting AIRmove²

Other manuals for AIRmove2

1

Table of contents

Other STOROpack Packaging Equipment manuals

Popular Packaging Equipment manuals by other brands

ITW Mima

ITW Mima Girotec RDL 1800 Service and installation manual

Tepack

Tepack ?4?-12 operating instructions

3M

3M AccuGlide HST 41000 Instructions and parts list

Catoma

Catoma Switchblade Frameset Operator's manual

3M

3M AccuGlide II STD Instructions and parts list

Siebeck

Siebeck JET 2000 Translation of the original operating manual