TABLE OF CONTENTS

1. SAFETY ................................................................................................................... 1

1.1 SAFETY RECOMMENDATIONS ............................................................................... 1

1.2 PERSONALSAFETY .................................................................................................... 2

1.3 FOOD SAFETY ............................................................................................................ 3

2. INSTALLATION..................................................................................................... 4

2.1 UNPACKING .................................................................................................................. 4

2.2 MOVINGTHE MACHINE ........................................................................................... 4

2.3 MACHINE

SPECIFICATI

ONS ..................................................................................... 5

2.4 ENVIRONMENT REQUIREMENTS .......................................................................... 5

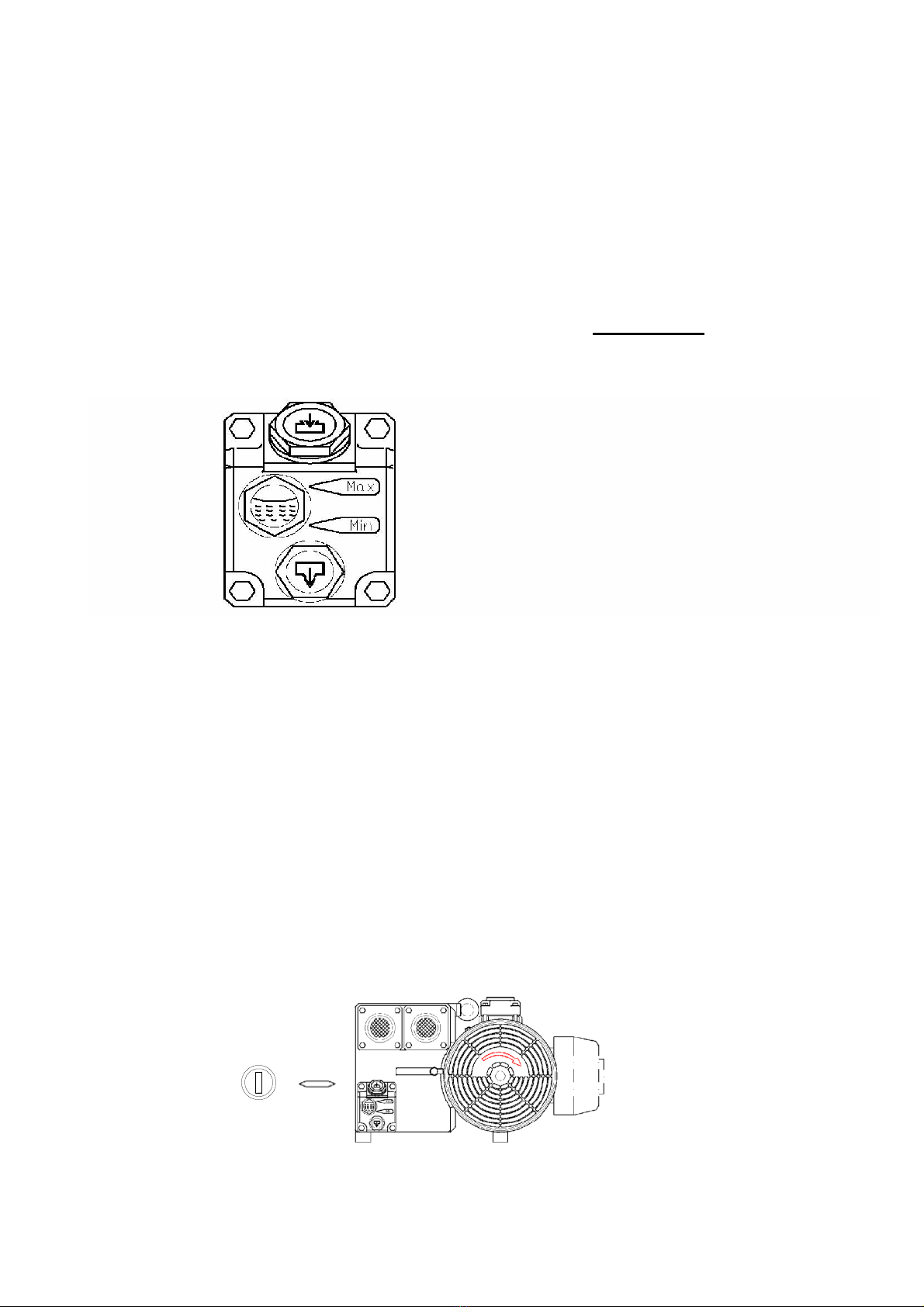

2.5 CHECK OIL LEVEL ..................................................................................................... 6

2.6 POWER CONNECTION ............................................................................................... 6

2.7 VACUUM PUMPROTATION ...................................................................................... 6

3. OPERATION........................................................................................................... 7

3.1 VACUUM SETTING GUIDELINES ............................................................................ 7

3.2 BASIC OPERATING INSTRUCTIONS ...................................................................... 7

3.3 OPTIONALDEVICE ..................................................................................................... 7

3.3.1 GAS FLUSHING UNIT ....................................................................................... 7

3.4 OPERATION OF THE PNC-01 DIGITALCONTROLPANEL ............................... 8

3.4.1 STANDARD MACHINE – BASIC INSTRUCTIONS ..................................... 8-9

3.4.2 SETTINGTHE PARAMETERS FOR THE OPTIONAL SETTINGS............ 10-12

4. MAINTENANCE .................................................................................................... 13

4.1 BASIC MAINTENANCE ............................................................................................. 13

4.1.1 DAILYVISUAL INSPECTION ......................................................................... 13

4.1.2 DAILY CLEANING ............................................................................................. 14

4.2 VACUUM PUMPMAINTENANCE ............................................................................. 14

4.3 SEALBAR MAINTENANCE ....................................................................................... 14-16

4.4 VACUUM VALVE MAINTENANCE ......................................................................... 15

4.4.1 VENT VALVE GREASING PROCEDURE ...................................................... 15

4.4.2 VACUUM VALVE GREASING PROCEDURE ................................................ 15-16

4.5 MAINTENANCE INTERVALCHART ....................................................................... 17

5. TROUBLESHOOTING ........................................................................................ 18

5.1 OPTIONAL DEVICE ..................................................................................................... 18

5.2 25 PIN D TYPE TERMINALWIRING CONNECTION INSTRUCTIONS ............ 19

5.3 PNEUMATIC DIAGRAM ............................................................................................. 20

5.4 ELECTRICALDIAGRAM (FB)..................................................................................... 21

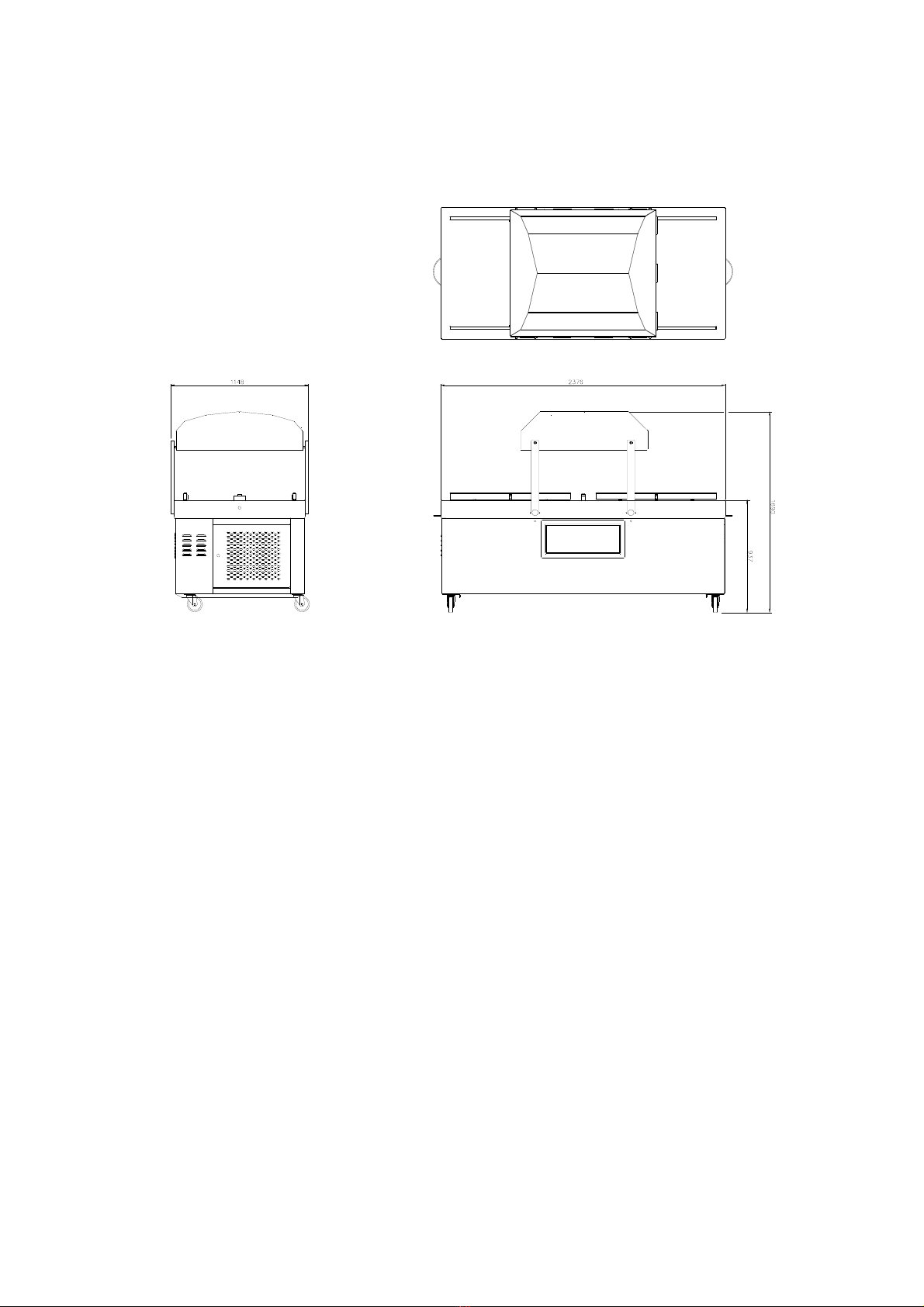

6. FABRICATION ..................................................................................................... 22

6.1 BODY DIAGRAM ........................................................................................................ 23-25

6.2 WORKING BED (BOTTOM) ....................................................................................... 26-29

6.3 SEALING BAR/ CUSHION BAR CONFIGURATIONS ........................................... 30

6.3.1 CUSHION BAR (FB)............................................................................................. 30-31

6.3.2 CUSHION BAR (PK) ............................................................................................ 30-33

6.4 CHAMBER LID,TOPDIAGRAM ................................................................................ 34-35

6.5 SEALING BAR CONFIGUATIONS,TOP ................................................................... 36

6.5.1 SEALING BAR (FB).............................................................................................. 36-38

6.5.2 SEALING BAR (PK)............................................................................................. 39-41